Falcon CNC Swiss is a specialized manufacturer of precision swiss machined electronic components, serving the world's most respected consumer technology brands in the world. We make high-precision, aesthetics-focused components that help define the user experience of aesthetic beauty devices and modern consumer electronics and wearables. In this business, aesthetic form factors and perfectly fulfilling functions go hand-in-hand, and Falcon CNC Swiss has the micron-level tolerances, inventive materials, perfect surface finishes to deliver compliant products to market.

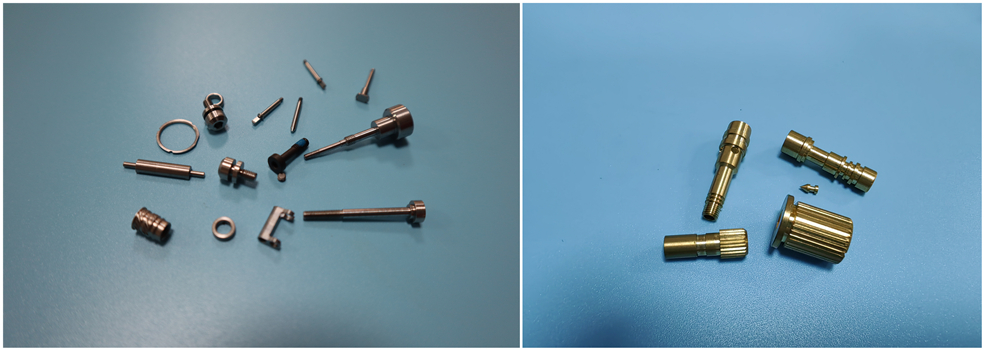

Swiss machining for electronics industry is important, because it allows for the precise and efficient production of small, complex components that are critical to the operation of electronic devices. In the electronics industry, Swiss machining is used to produce small components such as connectors, pins, and other precision parts. These components are often used in electronic devices such as smartphones, laptops, and medical equipment. They need to be produced with a high degree of precision to ensure that they function properly and reliably. The high precision and speed of Swiss machining make it possible to produce parts quickly and accurately, which is essential in the highly competitive electronics industry.

Precision Machining for Wearable Technology

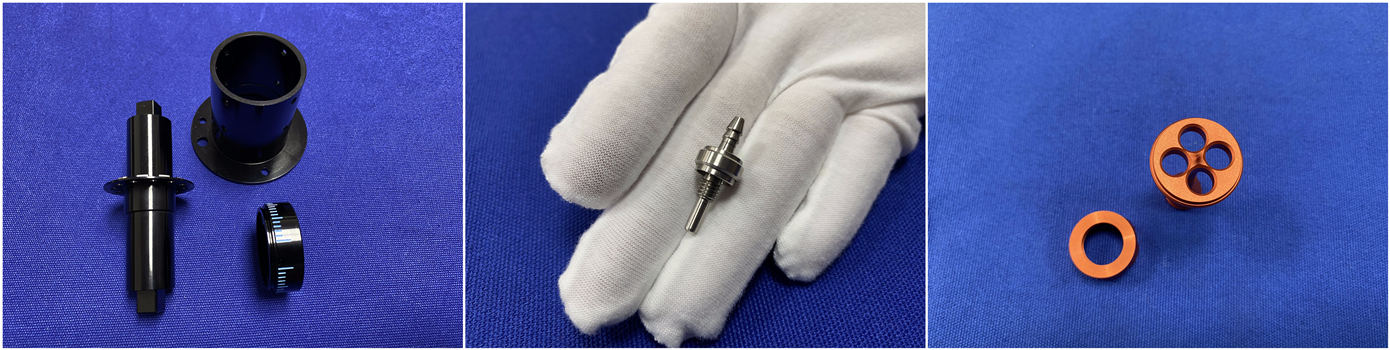

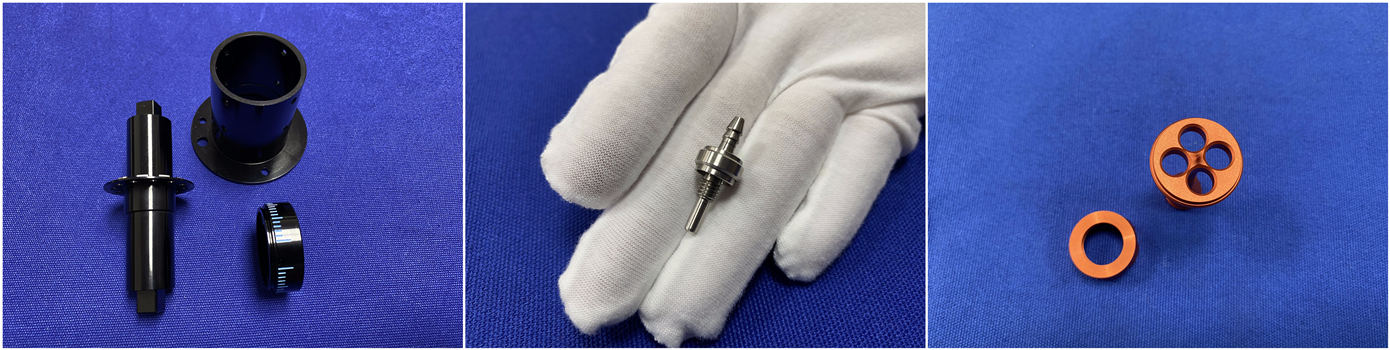

As the wearable technology category has grown, miniaturization and wearability have reached new levels. Our process capabilities in micro-machining and swiss CNC turning lend themselves perfectly to the reliability and performance of the miniaturization movement in the wearables area.

Key Wearable Components We Machine:

Smartwatch & Fitness Wearables: Casing/lugs/button shafts/sensor rings/internal structural components/service parts

Hearables (TWS Earbuds): Precision electronic contact pins, hinges, microphone casings, nozzle tips, frame structures

Augmented & Virtual Reality (AR/VR): Headset assembly components, adjusting mechanism components, sensor mounts with ultra-low weight and high accuracy requirements

Precision Engineering for Beauty and Personal Care Devices

The beauty device and medical device industry requires a delicate balance of biocompatible material, ergonomics, and an aesthetically beautiful finish that communicates luxury and efficacy.

Key Beauty Device Components We Machine:

Handheld Device Casings: Ergonomic casing for the handheld facial cleansing brush, anti-aging device, laser hair removal

Precision Nozzles and Tips: Components to control the fluid delivery systems for skincare providers and consumers.

Where Internal Mechanisms: Micro-gears, rotors, and shafts bring function to the device

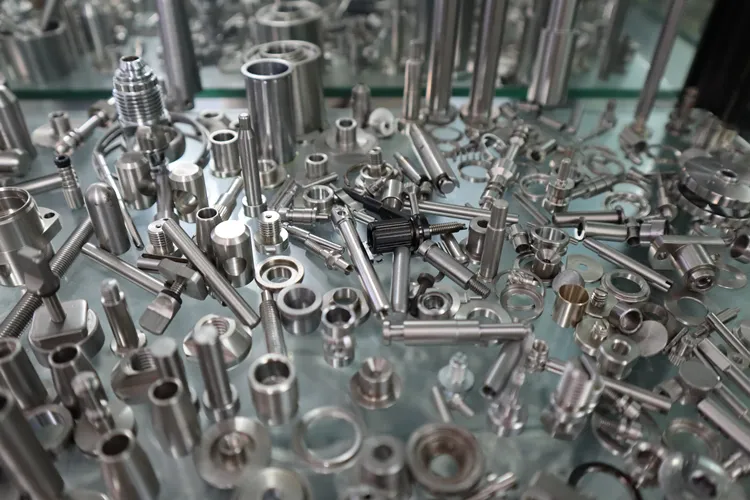

Our Core Consumer Electronics Capabilities

We support the broader electronics industry's larger parts and components that create the touchpoints to consumer electronic products.

Enclosures & Housings

We machine enclosures and housings for electronics in thin-walled, light weighted designs in aluminum, engineering plastics, or other durable/almost indestructible material without compromising on strength.

Connectors and Interfaces

Internal Assembly Components and Shielding

We provide critical parts and assemblies for the internal components of electronics or e-devices including heat sinks for thermal performance, EMI / RF shielding cans, structural supports or mounts, etc.

Why Falcon CNC Swiss is the right partner for your projects in the Electronics Products

Aesthetically Excellent

We know that surface finish is the single most important feature of the device for consumers. For that reason we can machine to aesthetic surfaces, available in these cosmetic grades:

Bead Blasting: Matte/fine texture

Precision anodizing: In many colours for branding and durability

Polishing and Brushing: Looks, feels, and performs like a premium product experience.

Leaders in Miniaturization

Our Swiss-type CNC lathes and multi-axis machining centres are optimized to machine very small, complex geometries and tolerances that no other conventional means can achieve. This makes us the ideal partner for micro electronic components machining and swiss screw machining electronics

We Are Built for Volume

We service the entire electronics industry! To support the consumer electronics industry in high volume manufacturing, we bring automated production cells and rigorous quality processes to every run of manufactured parts as part of the the consumer electronics supply chain.

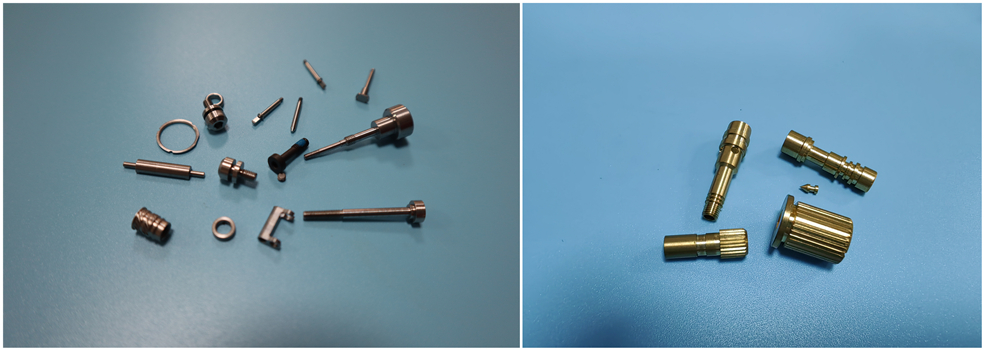

Swiss Machined Electronic Components: Pins, Connectors, Housings & More

Our Swiss machining services are a precise and efficient manufacturing process that is commonly used to produce electronic components, which can produce a wide range of precision electronic components.

Here are some types of Swiss-machined electronic components:

Connectors

Pins

Terminals

Screws

Housings

Contacts

Antennas

Sensors

Actuators

Client Success: High-volume machining of 5g antenna components (2M+/month) with 99.98% yield rate using in-process vision inspection. Check more electronics components made by our Swiss machining service→

Frequently Asked Questions (FAQ)

What materials are best for wearable technology?

Aluminum is lightweight and yields a nice finish quality and is therefore a common choice. Another common choice is stainless steel which has very high strength characteristics for small components. When biocompatibility is critical, such as in skin contact applications, medical grade PEEK and titanium are both commonly used for their strength to weight ratio.

What are your capabilities on "Apple-level" cosmetic finishes?

Absolutely. As an organization, we specialize in cosmetic surfaces and high-end finishes that meet the aesthetic requirements of the best consumer brands. Essentially, we will work with you to figure out the material and finishing process that achieves your intended look/feel.

Do you provide full assembly services for components?

We will provide value added services and packaging options including light assembly and ultrasonic cleaning of your components to get a complete sub-assembly for your production line and minimize part of your supply chain.

How do you ensure consistency in high volume runs?

Whether an order is big or small in high volume runs, we can ensure that every part in a production run - 1st to a millionth - is identical from component size, to make-up, to within specification, etc. Factory automation, CNC systems, and statistical process control (SPC) are just a couple of verification tools and methods we utilize.