Search

What are you looking for?

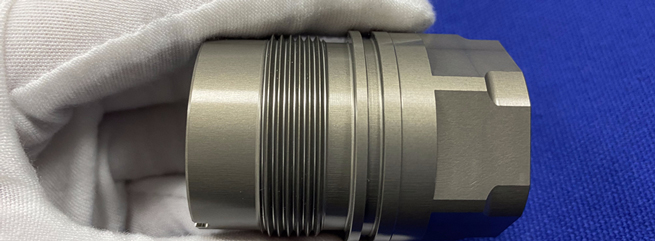

Titanium, as a challenging material, has a unique combination of properties in terms of high strength, high temperature, chemical reactivity, and elasticity. Due to its strength and tendency to harden during processing, it is difficult to cut using traditional machining techniques. Therefore, Swiss machining is the best choice in general.

Falcon Swiss machine shop is an expert in titanium machining and can ensure successful and efficient processing of titanium materials. We have a deep understanding of the unique properties and challenges of titanium and have developed specialized techniques and tools to overcome these challenges. Contact us now for your titanium manufacturing needs!

Titanium is a widely used material in Swiss machining due to its unique properties and numerous advantages. Here are some of the advantages of using titanium materials in Swiss machining:

High Strength-to-Weight Ratio: Titanium has an excellent strength-to-weight ratio, making it a popular choice for parts where weight reduction is critical. It is approximately 40% lighter than steel but has similar or greater strength.

Corrosion Resistance: Titanium has excellent corrosion resistance, particularly in harsh environments such as seawater or acidic environments. This property makes it a popular choice in the aerospace and marine industry. Using titanium materials in Swiss machining ensures long-lasting, corrosion-resistant parts.

Biocompatibility: Titanium is biocompatible, meaning it does not react with biological tissues or fluids. This property makes it an ideal choice for medical implants and devices. Swiss machining allows for the precise fabrication of complex medical components using titanium, ensuring a high degree of accuracy and compatibility with the human body.

High-Temperature Resistance: Titanium has a high melting point and can withstand high temperatures without deforming or losing strength. This property makes it suitable for use in high-temperature applications such as jet engines and gas turbines.

Low Thermal Expansion: Titanium has a low coefficient of thermal expansion, which means it expands and contracts minimally with temperature changes. This property is advantageous in applications where dimensional stability is critical, such as precision instruments or optical devices.

In Swiss machining, different grades of titanium can be used based on the specific requirements of the application. The selection of titanium grade depends on specific application requirements, such as strength, corrosion resistance, and biocompatibility. Here are some Falcon commonly used titanium grades in Swiss machining include:

Grade 2: Commercially pure titanium with excellent corrosion resistance and high strength.

Grade 5 (Ti-6Al-4V): Titanium alloy with a balance of strength, corrosion resistance, and formability.

Grade 9 (Ti-3Al-2.5V): Titanium alloy with good weldability, high strength, and corrosion resistance.

Grade 23 (Ti-6Al-4V ELI): Variant of Grade 5 with extra-low interstitials, commonly used in medical applications.

The best grade of titanium for machining depends on the specific requirements of the application and the machining process being used. However, Grade 5 and Grade 2 titanium are the most commonly used grades for Swiss machining due to their excellent properties and availability.

Swiss machined titanium parts find application in various industries due to their exceptional properties. Their superior properties make them an ideal choice for applications that demand strength, durability, corrosion resistance, and lightweight characteristics. Here are some common applications:

Aerospace components: turbine blades, structural components, and engine parts

Medical components: surgical instruments, dental implants, spinal implants, and orthopedic implants

Automotive components: engine valves, connecting rods, and suspension parts.

Consumer electronics: smartwatch cases, lens mounts and tripod sockets, audio components

Oil and Gas: Offshore drilling equipment components, valves, pumps

Optical components: mounts, telescope components

Equipment components: gears, screws, shafts.connectors

By applying surface treatments to titanium components in Swiss machining can enhance their properties and improve their performance in specific applications. The treatments help protect against corrosion, enhance wear resistance, improve lubricity, provide aesthetic options, promote biocompatibility, and facilitate adhesion or bonding, ultimately ensuring the quality and longevity of the Swiss machined titanium parts. Some common surface treatments for titanium include:

Bead Blasting

Anodizing

Powder coating

Passivation

Polishing

Plating

and more...