Optical Companies Trust Falcon Micromachining Techniques

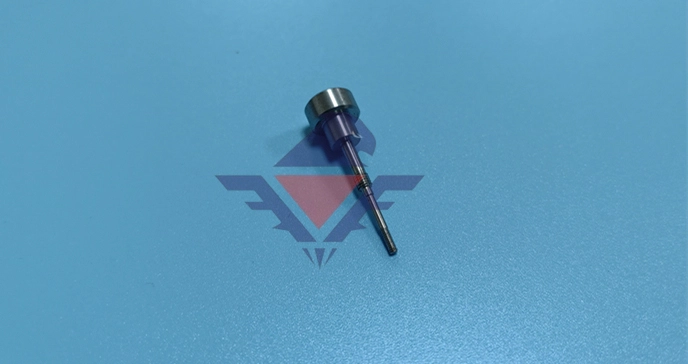

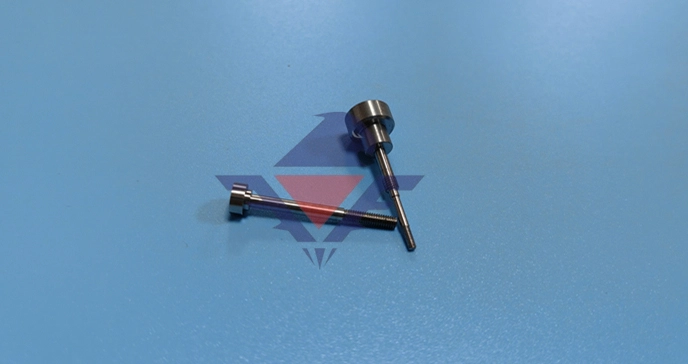

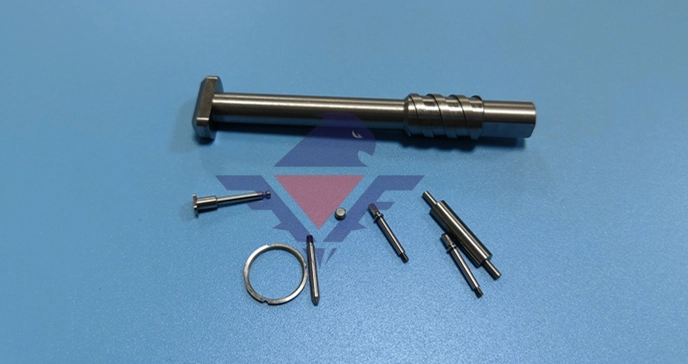

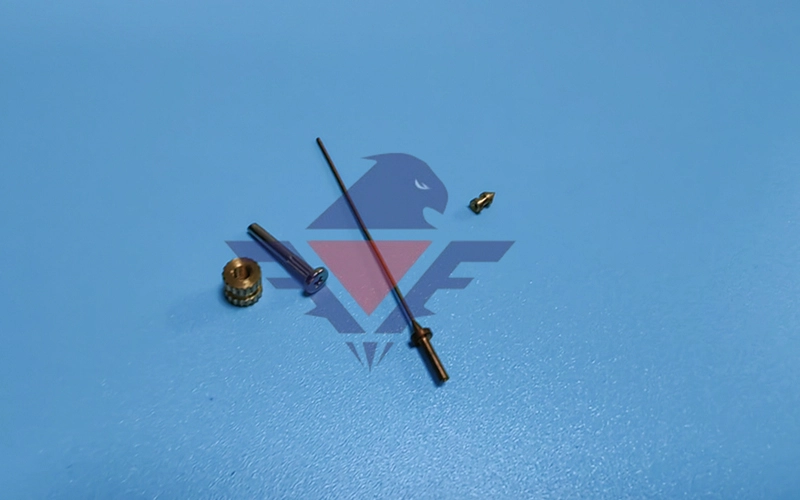

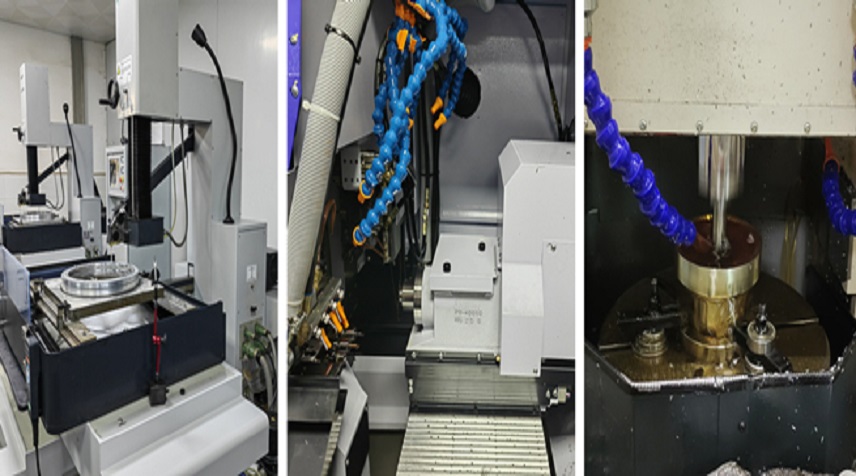

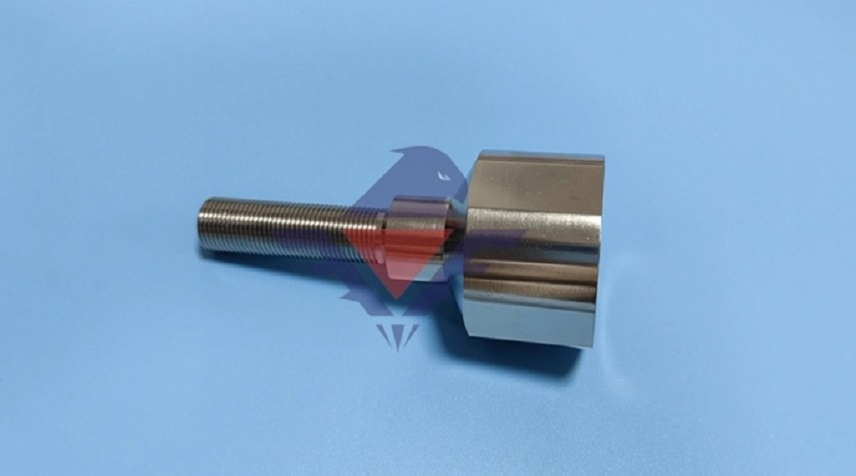

The optical components require extremely high processing precision, smoothness, and assembly accuracy to ensure a perfect match with complex equipment such as microscopes, laser displays, and telescopes. Falcon micro-processing technology is equipped with advanced 5-axis processing equipment, Swiss lathe processing, and EDM and WEDM processes, which can produce extremely complex and precise optical micro parts.

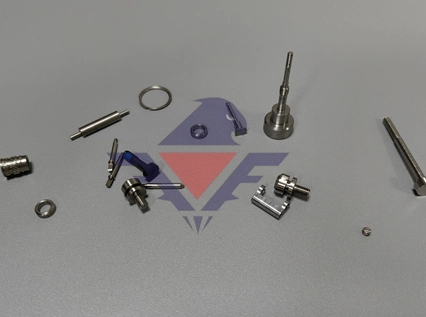

The optical parts manufactured by Falcon can be magnified up to 70 times under a microscope without burrs, which can greatly help the equipment to operate stably and quietly. Commonly produced optical components include spacers and bushings in the optical field, electron microscope accessories, fiber optic components including MEMs, collimators, and other optical switching elements, microwave ferrites (ceramics), acoustic nozzles, and VAD impellers, etc.