Search

What are you looking for?

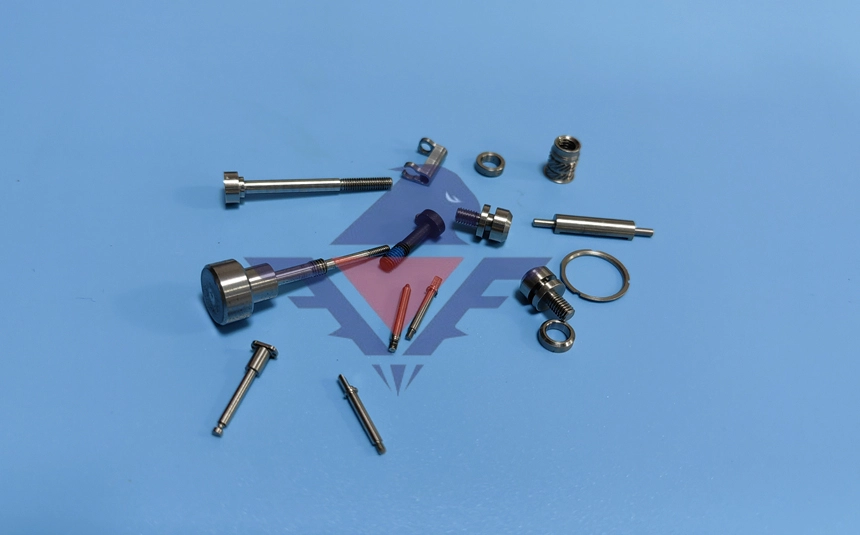

Swiss machining is a type of precision machining that utilizes specialized lathes to produce small, complex parts with high accuracy and surface finishes. The process of precision swiss machining involves the use of a sliding headstock that holds the workpiece and rotates it while a series of stationary cutting tools remove material from the rotating part. This method allows for the creation of intricate designs, tight tolerances, and consistent quality in high volume production.

The main difference between Swiss machining and traditional machining techniques is the way the workpiece is held during the machining process. In traditional machining processes, the tool and the workpiece are both moving during the cutting process. In precision Swiss machining and screw machining, the workpiece moves through a guide bushing while the tools remain stationary. This allows for greater precision and control of the cutting process, especially for small and complex parts.