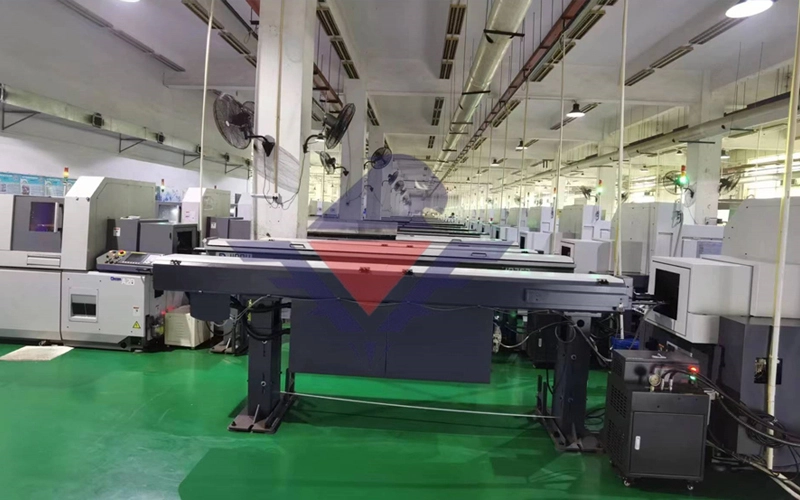

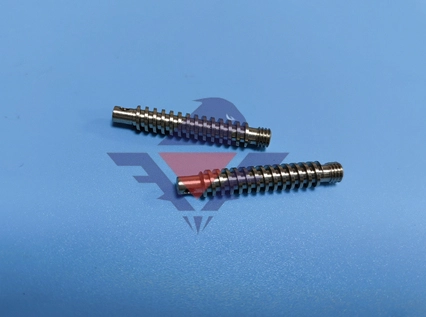

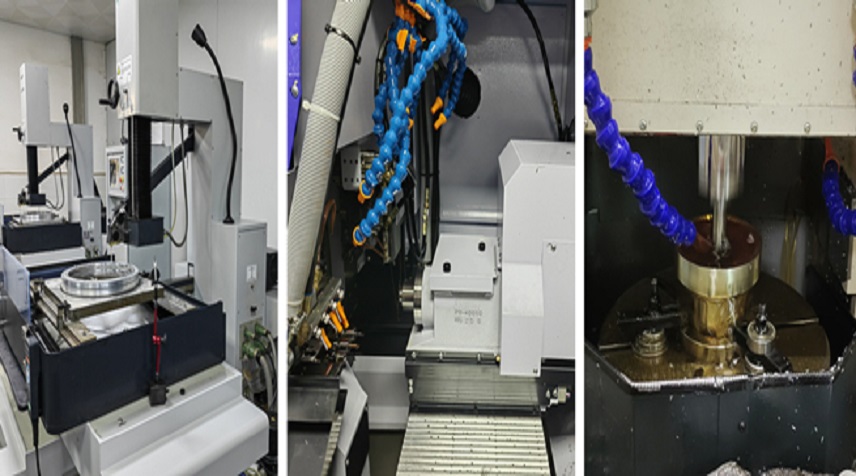

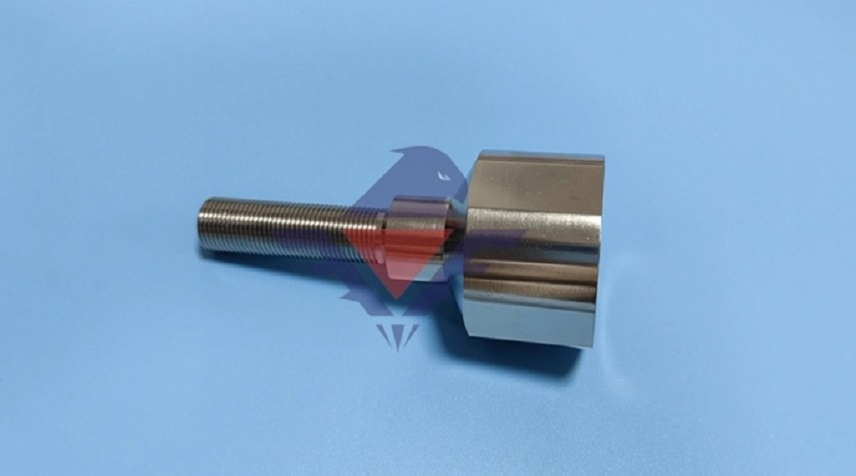

Our Swiss turning service utilizes state-of-the-art technology and highly skilled operators to produce parts with unparalleled precision and accuracy. This ensures that our customers receive high-quality parts that meet their exact specifications. With 300 machines and equipment, we are able to provide one-stop service from prototype to mass production. This means that our customers can receive their parts in a shorter amount of time, which can help them to meet tight deadlines and reduce lead times.

① On-Demand Manufacturing: With over 300 pieces of equipment, we are fully equipped to meet the demands of your manufacturing needs, whether it be for small or large batch orders.(100-1,000,000 pcs per month)

② Quality assurance: Comprehensive quality control system with strict standards for incoming inspection, process inspection, inbound inspection, and outbound inspection, ensuring that every part we produced is of high quality and high accuracy. We can provide test reports such as FAI/QC/RoHS as required.

③ Certification: Our certifications include ISO 9001 for quality management, ISO 14001 for environmental management, ISO 13485 for medical device quality management, and ISO 16949 for automotive quality management.

④ More Options: Strict compliance with PPAP and FMEA for automotive and medical clients. 475 material processing methods, 28 CNC techniques, and 30 kinds of surface treatments.