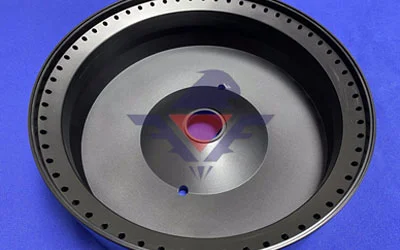

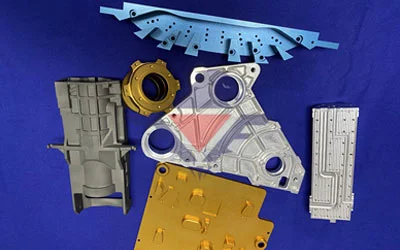

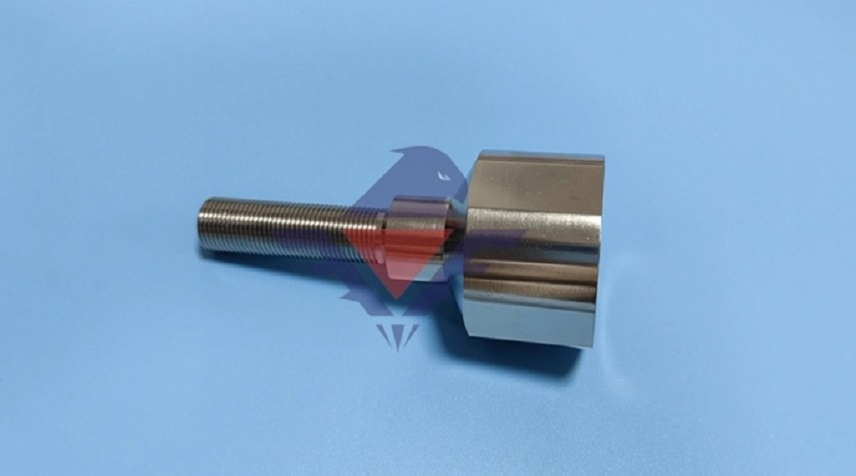

Falcon offers a wide range of surface treatment options, including coatings, plating, and finishes, to enhance the durability, corrosion resistance, and aesthetics of your components, ensuring they meet the specific requirements of your industry and application.

Search

What are you looking for?