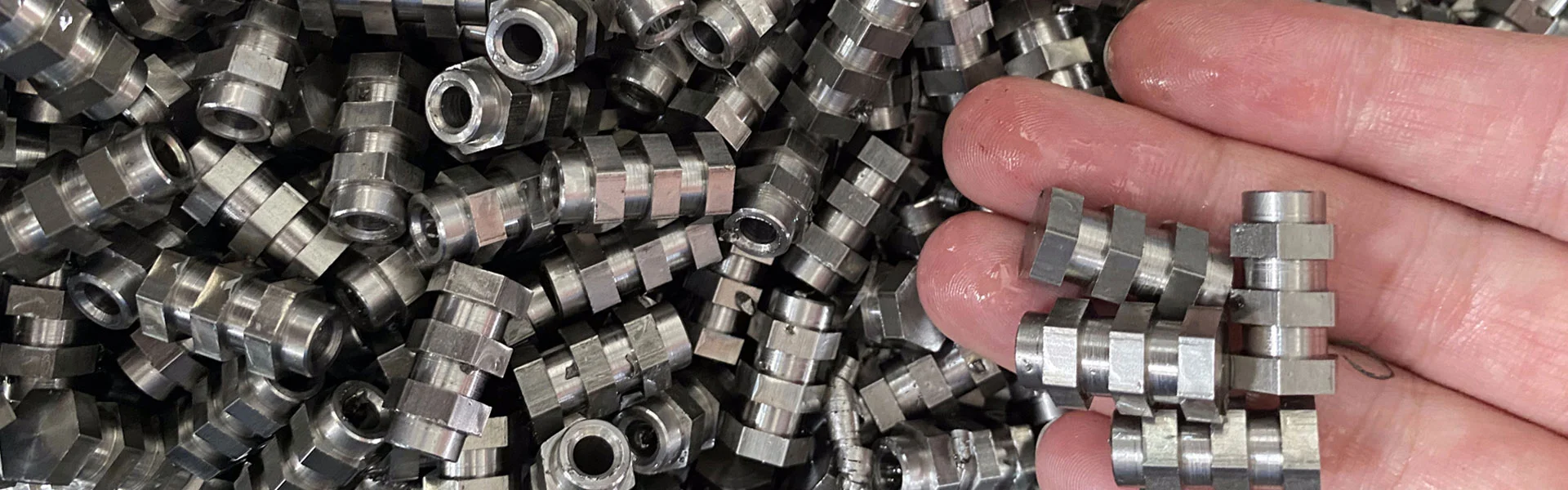

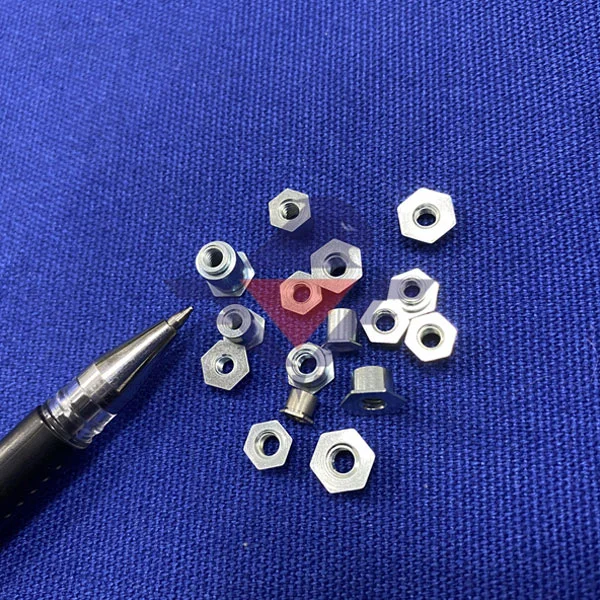

Falcon's Swiss machining capabilities offer exceptional precision and the ability to achieve tight tolerances, ensuring the production of parts with consistent and accurate dimensions. This is critical for industries that demand exacting specifications, such as aerospace, defense, and medical device manufacturing.

Search

What are you looking for?