Search

What are you looking for?

Plastic materials are widely used in a variety of industries due to their versatility, low cost, and ease of processing. Several types of machining processes can be used to machine plastic materials, such as CNC Swiss machining, Swiss turning, milling, and drilling. Here are some most commonly machined plastic materials used in Swiss machining:

Acetal (POM) - a tough, low-friction plastic that is often used for gears, bearings, and other small parts that require high wear resistance.

Polycarbonate (PC) - a strong, transparent plastic that is used for optical applications, such as lenses and covers.

Nylon - a tough, wear-resistant plastic that is often used for gears, bearings, and other small parts that require high strength and durability.

Polypropylene (PP) - a lightweight, flexible plastic that is used for a variety of applications, including packaging, medical devices, and automotive parts.

Acrylic (PMMA) - a transparent plastic that is often used for displays, lighting fixtures, and other applications that require optical clarity.

| √ PEEK (Polyetheretherketone) | √ PTFE (Polytetrafluoroethylene) | ||

| √ PVC | √ PE (Polyethylene ) | ||

| √ ABS | √ PET |

Falcon offers a comprehensive range of machining capabilities, including CNC Swiss Machining, Swiss turning, and micro precision machining. This diverse set of capabilities allows us to provide customized solutions for any type of machined plastic needs our customers may have. Here are some advantages of Swiss machined plastic parts:

Design Flexibility: It can be easily customized to meet specific design requirements. The machining process allows for the creation of complex shapes, intricate features, and precise geometries

Lightweight: Plastic materials are inherently lightweight, making plastic machined parts ideal for applications where weight reduction is crucial.

Cost-Effective: Plastic machined parts often offer cost advantages over other materials such as metals.

Corrosion Resistance: Many plastic materials exhibit excellent resistance to corrosion and chemicals, making them suitable materials for parts used in harsh environments.

Low Friction and Wear: Certain plastic materials, such as PTFE (polytetrafluoroethylene) or UHMW (ultra-high molecular weight polyethylene), exhibit low friction and excellent wear resistance.

Thermal Insulation: Plastic materials often have good thermal insulation properties, which can be advantageous in applications.

Swiss machining is a high-precision machining process that is commonly used to produce small, complex parts with tight tolerances. Plastics can be used in Swiss machining applications due to their excellent machinability, low coefficient of friction, and good chemical and wear resistance. Some common applications of plastics in Swiss machining include:

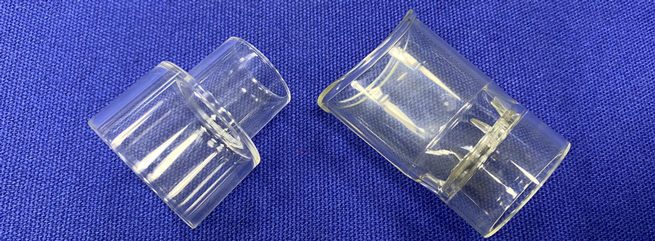

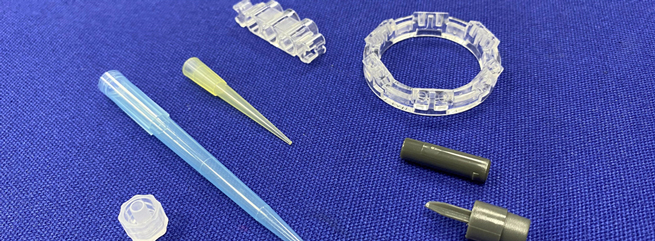

MedicalDevices: Swiss machining is commonly used to produce small, complex medical devices, such as implants, surgical instruments, and diagnostic tools. Plastics such as PEEK (polyether ether ketone) and Ultem (polyetherimide) are often used in these applications due to their biocompatibility and ability to withstand sterilization.

Electronics: Plastics such as nylon and polycarbonate are commonly used in electronics applications due to their electrical insulation properties and good dimensional stability. Swiss machining is often used to produce small, complex parts such as connectors, housings, and insulators.

Automotive: Plastics such as acetal and ABS (acrylonitrile-butadiene-styrene) are commonly used in automotive applications due to their high strength and resistance to impact and chemicals. Swiss machining is often used to produce small, complex parts such as gears, bearings, and bushings.

| Connectors | Bushings | ||

| Housings | Inserts | ||

| Gears | Knobs | ||

| Fittings | Insulators | ||

| Screws | Fasteners |

At Falcon, we understand the importance of quality, efficiency, and reliability. Our state-of-the-art machinery and advanced manufacturing processes enable us to deliver top-notch products with consistent quality over the years.

Whether you require complex and intricate parts or simple components, you can rely on Falcon for precision machining and exceptional service. We are dedicated to delivering high-quality, custom machined plastic parts that meet the stringent demands of various industries. Contact us today to learn more about our CNC Swiss machining capabilities and how we can help you with your next project.