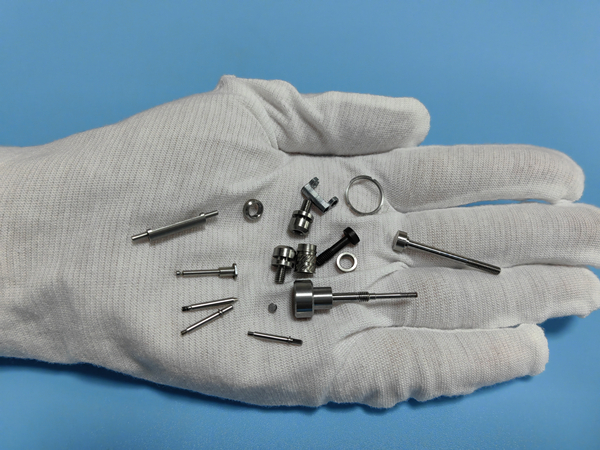

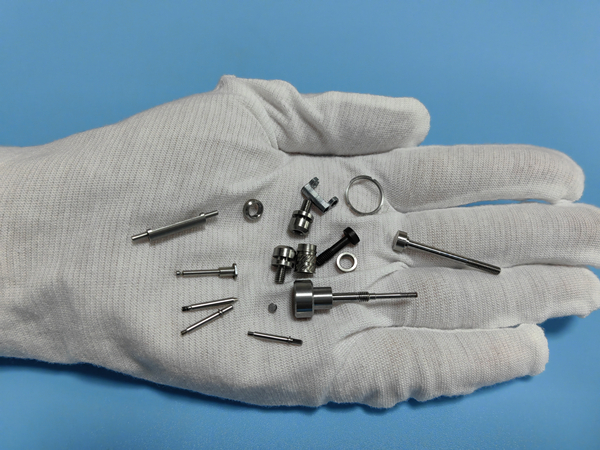

Micro precision machining is a highly specialized manufacturing process that requires the use of advanced equipment and skilled operators to produce small, precise, and accurate components. One of the critical factors that determine the quality and performance of micro machined components is the selection of materials and surface treatment.

Materials Selection

Choosing the right material is crucial to achieving the desired properties and performance of micro-precision components. The material selected must have the required strength, stiffness, toughness, and durability, depending on the application.

Common materials used in CNC precision micro machining include:

Stainless Steel - This is a highly versatile material that offers excellent resistance to corrosion, heat, and chemicals. It is commonly used in medical and dental implants, aerospace components, and precision instruments.

Aluminum - Aluminum is lightweight, durable, and highly resistant to corrosion. It is commonly used in the automotive industry, aerospace, and electronics.

Titanium - Titanium is known for its high strength-to-weight ratio, making it ideal for use in aerospace and medical implants.

Plastics - Plastics are highly versatile and can be used in a wide range of applications, including medical devices, electronics, and automotive components.

Surface Treatment

Surface treatment is another critical aspect of CNC precision micro machining. The surface finish of a component can have a significant impact on its performance, including its ability to withstand wear, corrosion, and fatigue. Common surface treatments used in CNC precision micro machining include:

Anodizing - This is a process that involves the creation of an oxide layer on the surface of the component, which provides increased corrosion resistance and improved wear resistance.

Passivation - This is a process that removes free iron and other contaminants from the surface of the component, which improves corrosion resistance.

Passivation - This is a process that removes free iron and other contaminants from the surface of the component, which improves corrosion resistance.

Heat Treatment - This is a process that involves heating and cooling the component to alter its properties, such as its hardness, strength, and ductility.

At Falcon, we have extensive experience in CNC micro precision machining and have the expertise to select the right materials and surface treatment to meet the specific needs of our customers. We work closely with our customers to understand their requirements and ensure that the components we produce meet the highest standards of quality and performance.

In conclusion, the selection of materials and surface treatment is critical to achieving the desired properties and performance of CNC precision micro machined components. At Falcon, we have the expertise and experience to select the right materials and surface treatment to meet the specific needs of our customers. If you are looking for a reliable manufacturing partner for your precision components, contact us today.