Titanium CNC Machining Capabilities

We are experts in CNC machining titanium parts for high-performance and high-precision components in a wide range of industries including aerospace, medical, energy, and defense. While titanium boasts a remarkable strength-to-weight ratio, further increased corrosion resistance, and biocompatibility, it has different machining considerations and issues due to work hardening and poor thermal conductivity.

To achieve precise repeated tolerances, Falcon CNC Swiss relies on the following factors:

Swiss type CNC machining for small-diameter titanium components

Multi-axis CNC milling and turning to achieve more complex geometries

Wire EDM to machine features of titanium to critical tolerances

Full capabilities for Grade 2, Grade 5 (Ti-6Al-4V), and medical-grade titanium

| Capability | Details |

| Max Tolerance | ±0.001 mm |

| Surface Finishes | Polishing, bead blasting, passivation |

| Precision Machining Process | Swiss turning, 5-axis milling, wire EDM |

| Supported Grades | Grade 2, Grade 5, Grade 23 (ELI) |

| Part Size Range | Ø0.2 mm – 200 mm, up to 500 mm length |

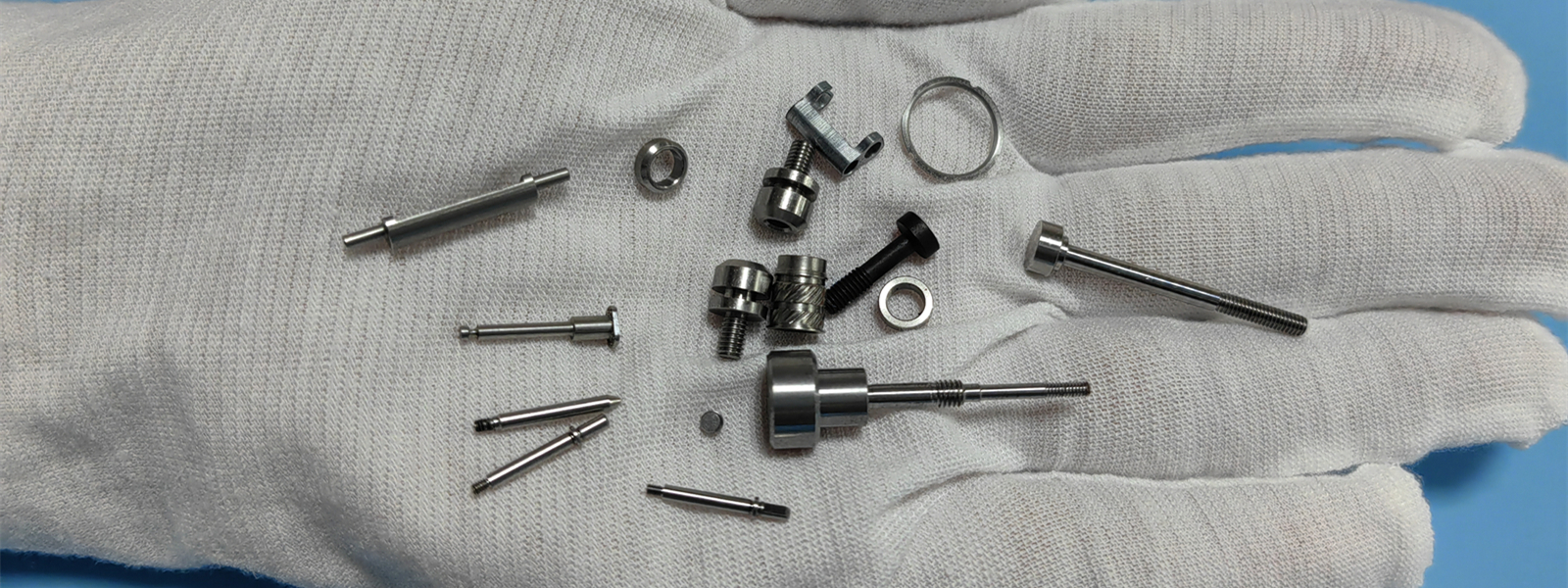

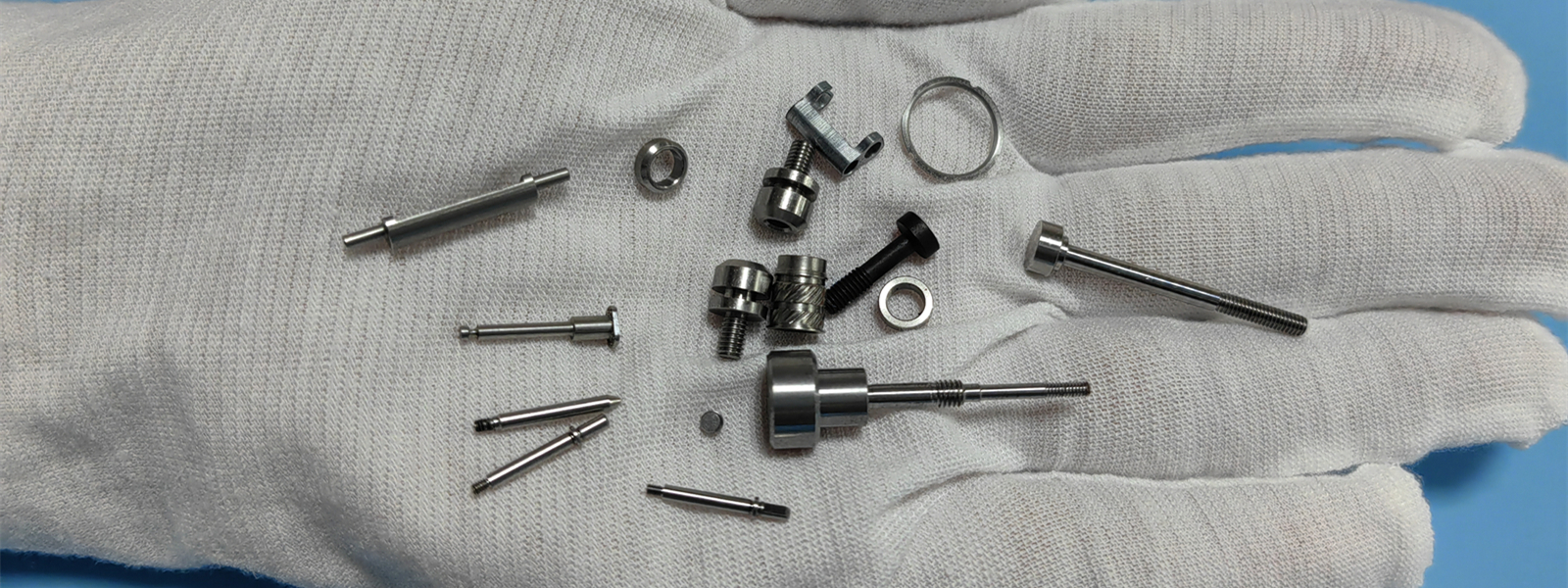

Custom Titanium Components Manufacturing

We deliver custom machined titanium components to your exact specifications, CAD drawings, or 3D models! We'll manufacture for prototype development or OEM production and provide precision machined, clean, titanium parts.

Materials and services we provide:

Rapid prototyping of CNC titanium components

Complete batch production of titanium components with tight tolerances

Material sourcing with mill certification

Inspection reports, including compliance with ISO 9001:2015

Common components we manufacture:

Titanium surgical devices and implants

Aerospace fasteners and structural components

Titanium housings and fittings for industrial applications

Heat exchangers and tubing connections

Our Custom CNC Machining Services are excellent for your project when high strength, low weight, and corrosion resistance are paramount.

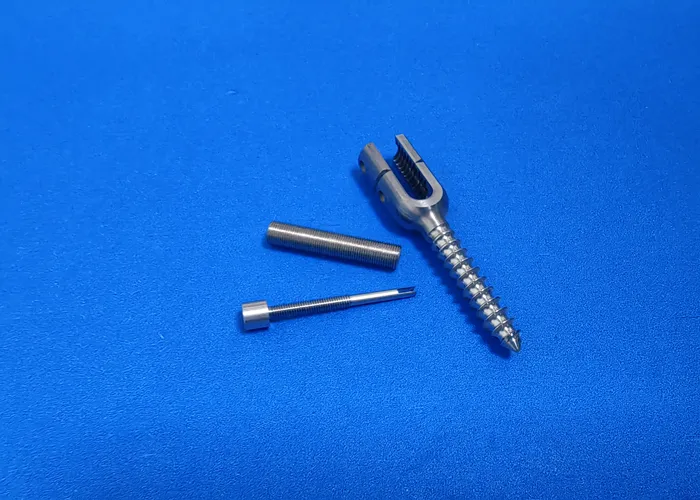

Highly Precise Turned Titanium Components

Turning titanium is complex – it requires specialized tooling, speed control and chip management. Falcon CNC has years of experience in refining all three. Our precision turned titanium components are made on advanced Swiss-type CNC lathes and multi-axis turning centers.

Examples of precision applications include:

- Orthopedic screws, pins, rods

- Robotics titanium shafts and sleeves

- Fluid system connectors and pressure-resistant components

- Aerospace RF shielding housings

We offer:

- Surface finishes to Ra 0.2 μm

- 100% dimensional inspection and traceability

- Tight tolerances for concentricity and roundness

- View our precision Swiss machinning services to see examples of our titanium work.

Titanium Component Manufacturer Network

As a trusted titanium CNC parts supplier and manufacturer, Falcon CNC Swiss works with a large network of B2B clients across North America, Europe, and Asia. We work with companies to reduce costs, and improve lead time by vertically integrating titanium machining under one roof.

Manufacturer benefits:

- ISO 9001:2015 certified titanium machining facility

- Global delivery to the USA, Canada, Germany, UK, and others

- Support for low, medium, and high volume production

- Dedicated project managers and engineering support

We welcome inquiries from:

- OEM buyers searching for titanium part manufacturers in China

- Medical device developers looking for biocompatible titanium components

- Distributors looking for titanium fittings and turned parts

Connect with our CNC Swiss Machine Shop for your international supply chain.

Why Choose Falcon CNC Titanium Machine Shop?

Falcon CNC Swiss brings extensive knowledge of titanium machining to deliver precision parts, with high repeatability and savings in machining costs. Our engineering department is familiar with titanium's physical properties and adopts tool strategies to prevent wear, plan to generate heat, and protect material integrity.

Why clients choose Falcon CNC Swiss:

- 20+ years of titanium machining experience

- High-end equipment - Citizen, Tsugami, Star Swiss lathes

- DFM assistance, 3D simulation, and CAM optimization

- Titanium parts manufacturing from prototype to full production

- Delivery on time, flexible minimum order quantity. Global delivery to global supply chain partners.

Whether you need titanium components, custom titanium parts or a certified titanium machining supplier, Falcon CNC Swiss is there to work with you. Contact us now for a quote on your CNC machining titanium project.