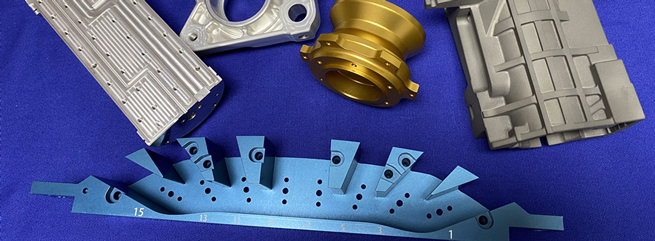

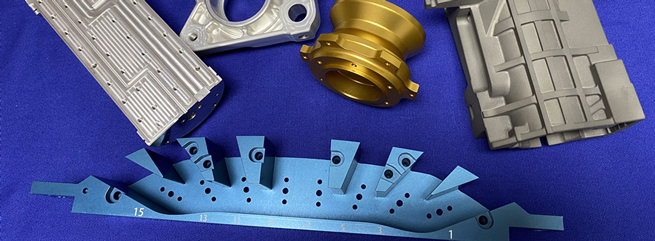

Falcon CNC Swiss is a trusted machinery parts machining supplier and manufacturer of critical high-strength components for the industrial machinery and fluid power sectors. We specialize in precision CNC machining for machinery to deliver the durable, reliable parts that keep heavy equipment, automation systems, and hydraulic circuits operating under extreme pressure, repetitive cycles, and demanding environments. When downtime is not an option, manufacturers and OEMs rely on our precision machining to deliver the quality, consistency, and performance their applications require.

Our high-volume swiss machining services for mechanical industries handle hardened steels up to hrc 60, specializing in complex geometries like differential gears and hydraulic valve bodies with ±0.002mm tolerance.

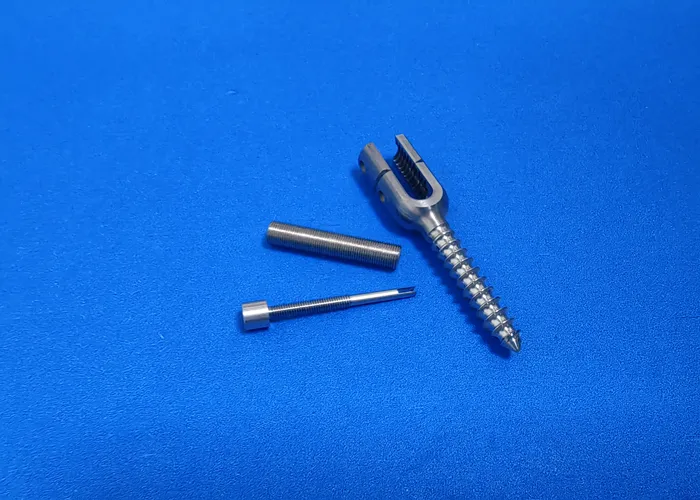

For over 20 years, Falcon's engineering team has been dedicated to providing high precision Swiss machining services for custom-made precision components such as bolts, nuts, screws, pins, shafts, and other precision parts for the global equipment industry, providing strong support for equipment R&D in various industries. We offer one-stop services from prototyping to mass production.

Machine Components Manufacturer for Hydraulic & Pneumatic Systems

As your custom machinery parts manufacturer, we produce reliable hydraulic components, reliability in a fluid power system comes from the precision of the components; leaks and breakdowns often come from poorly machined components. We manufacture components that house high-pressure seals and hold precise tolerances in order to ensure system efficiency and longevity.

Key hydraulic components we machine:

Valve Bodies & Spools: Complex valve body machining, used in directional, pressure and flow control valves, with holding the critical tolerances to operate smoothly, and prevent internal leakage from the spool body.

Piston Rods and Cylinder Components: Piston rod machining for hydraulic & pneumatic cylinders, requiring superior surface finishes for the prolonged life for seals, and straightness for optimal use.

Pump & Motor Parts: Components made for gear pumps, vanes, and pistons that hold close tolerances, and require wear resistant properties.

Manifold Blocks: Complex manifold block machining that has intricate internal passageways to incorporate plumbing, and decrease potential leak points.

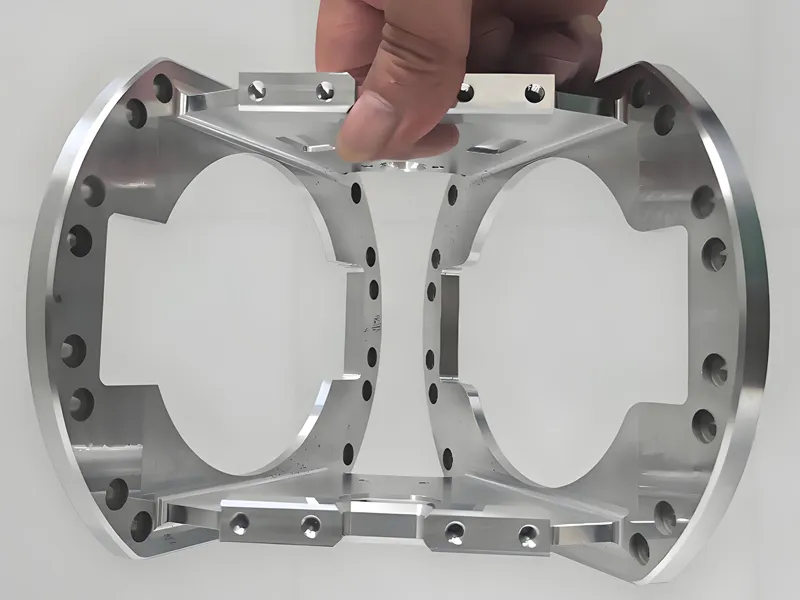

Precision Machine Parts for Industrial Machinery & Automation

We provide high precision machinery components for industrial automation and equipment, from floor production lines to construction sites, all use rugged components designed to withstand high loads, impacts, and constant use.

Key manufacturing machine parts:

Shafts and Axles: Precision CNC shaft machining for drives, conveyors, and gearboxes require strict limits, for diameter, concentricity and surface finishes.

Gears and Sprockets: Machined gears, for power transmission applications that require accurate tooth profiles and heat treating.

Custom Fasteners: High-strength threaded fasteners, studs and pins that are typically made from hardened materials to hold important connections.

Machine Tool Components: Components require for jigs and fixtures and automation equipment focus on rigidity and precision.

Our Capabilities for Demanding Applications

These comprehensive capabilities make us your ideal partner for oem machinery components machining and industrial machinery parts machining.

Material Knowledge for Strength and Durability

We are expert machinists from a large list of high strength materials used for industrial applications, including:

Carbon & Alloy Steels: (i.e. 4140, 4340) for mechanical strength and toughness.

Stainless Steels: (i.e. 303, 304, 316, 17-4 PH) for corrosion resistant.

Ductile Iron and Cast Iron: for wear resistance and damping qualities.

Bronze and Brass: for bushings, bearings, and wear plates.

Secondary Processes for Part Performance

We are a full-service provider of finishing to meet specifications:

Heat Treating & Hardening: Increase surface wear resistance, and improve core strength.

Plating & Coating: (i.e., Chrome Plating; Nickel Plating) enhance the surface properties and help with corrosion and impact resistant.

Grinding: Ultra-precise dimensions, and superior surface finishes on hardened materials.

Quality Built for Reliability

As a machinery spare parts manufacturer and supplier, we know a failed component can disrupt and stop the entire production line. Our comprehensive quality assurance program for each component includes first-article inspection (FAI), in-process check and final layout report to ensure every part meets the demanding requirements set by the industrial sector.

Why Partner with Falcon CNC Swiss?

Deep Knowledge of the Industry

Because we can do anything from Prototype to Production

We partner with you at all phases from prototyping new designs to high-volume production runs. With our support, you can be assured of a seamless transition with your new parts, while ensuring parts consistency.

Solution-Focused

Don't let failure of components be your cause of downtime. Partner with Falcon CNC Swiss for precision machinery parts built with Reliability and Performance! Need parts in 5 days? lock your production slot now →

Frequently Asked Questions (FAQ)

What tolerances can you hold for hydraulic components?

We routinely hold tolerances of ±0.0005" (0.0127mm) or tighter on critical sealing surfaces and diameters to prevent leaks and enable hydraulic components to function properly.

Can you machine and finish hard steels?

Yes. We can machine pre-hardened steels and perform secondary operations like grinding to the harder material to achieve final dimensions with exceptional surface finishes.

Do you assist with material selection?

Definitely, we can help with material selection relative to your application, comparing the various properties such as strength, corrosion resistance, wear, and cost.

How do you maintain consistency on parts in long production runs?

With our automatic CNC equipment and statistical process control (SPC), we ensure that every part in the family, from part one to part ten-thousand, is consistently, reliably, and assuredly to your specifications.