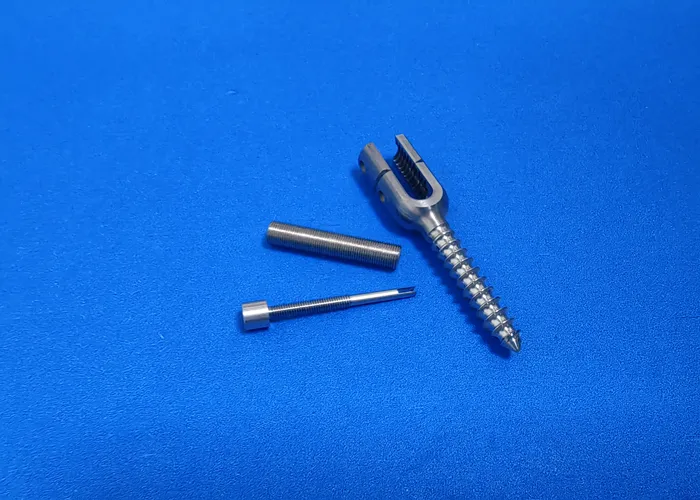

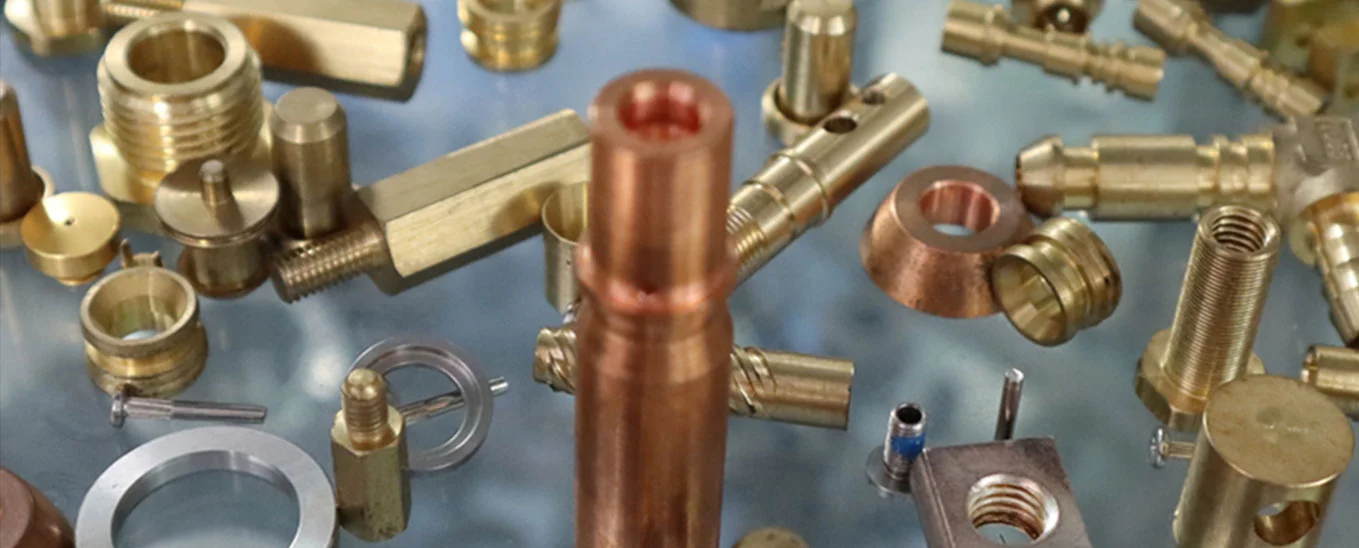

Welcome to Falcon Swiss Machining Factory, your premier source for high-precision manufacturing solutions. With a commitment to quality, reliability, and customer satisfaction, we provide a wide range of services including Swiss Machining, Screw Machining, Micromachining, and EDM/WEDM. Our advanced technology, skilled machinists, and state-of-the-art equipment allow us to produce even the most complex and challenging parts with unmatched precision and accuracy.

At Falcon Swiss Machining, we understand the importance of quality and precision in manufacturing, which is why we hold certifications in ISO 9001, 13485, and 36949. These certifications are a testament to our commitment to quality and our dedication to providing exceptional service to our customers.

Our machining precision factory is equipped with over 300 sets of Swiss machines and other advanced equipment, allowing us to handle any project, no matter the size or complexity. Our team of experienced and highly skilled machinists is committed to delivering superior quality parts with a focus on efficiency, accuracy, and consistency.

As a leading provider of precision machining solutions, we cater to a wide range of industries including aerospace, medical, and electronics, among others. Our ability to work with diverse materials and produce parts to tight tolerances makes us a go-to choice for precision engineering needs.

At Falcon Swiss Machining Factory, we pride ourselves on providing high-quality precision machining services with a focus on excellence in everything we do. Contact us today to learn more about how we can help take your manufacturing needs to the next level.

Jill

Jill