At Falcon CNC Swiss, the investment and efforts we put into advanced manufacturing technology is our commitment to you and your success. We are not a machine shop, we are your scalable CNC production partner for your high volume CNC production runs with consistency, speed, and accuracy like no other.

We have built our facility with automated CNC machining for the highest volume, utilizing over 300 of our advanced machines with lean manufacturing principles to become the best contract manufacturer for high volume.

1. Equipment & Processing Capabilities for Automation

We believe our suite of equipment is specially selected for high volume CNC machining services, speed, automation, and reliability.

No. | Equipment Name | Brand & Manufactory | Model | Q'ty | Tolerance (mm) |

1 | CNC Machining Center | Brother / Japan | S500Z1 (21 tools) | 50 | 0.005 |

4 | 5-Axis | Tsudakoma / Japan | TN-101 | 1 | 0.005 |

5 | 5-Axis | Kitagawa / Japan | TT101ASV01 | 45 | 0.005 |

6 | 5-Axis | Tanka / Taiwan | FAR-125-HVP | 4 | 0.005 |

7 | 4-Axis Rotary Table | Tsudakoma / Japan | RWE-160L | 12 | 0.005 |

8 | 4-Axis Rotary Table | Tsudakoma / Japan | RWE-200L | 4 | 0.005 |

9 | 4-Axis Rotary Table | Kitagawa / Japan | MR162RAS71 | 5 | 0.005 |

10 | CNC Swiss Machines | Tsugami / Japan | B0205 | 134 | 0.005 |

13 | CNC Turn machines | Jiecheng / China | Model 36 | 87 | 0.005 |

15 | CNC Lathes | Saints / China | Model 45 | 1 | 0.005 |

16 | CNC Swiss Lathes | Jiecheng / China | D206 / 366 | 3 | 0.005 |

18 | Gear Hobbing Machines | Milet / China | N120H | 9 | ISO6 |

19 | Wire EDM | Susanguang / China | HB400 | 1 | 0.005 |

20 | Surface Grinder | Okamoto / Japan | ACC350II | 1 | 0.002 |

21 | Laser Engraver | Chongtian / Han's Laser / China | CTL-M20F

CTL-M15W-355

HM20-S | 4 | 0.01 |

Your Automation and Tooling Advantages:

Robotic Loading: Unattended high-volume production with automated part loading/unloading.

Tool Management: Industry-leading tool presetters and monitoring tools calculate use and waste of tools to prevent costly stoppages.

Quick-Change Fixturing: Non-proprietary workholding fixtures providing a spacecraft-standard free job changeover cost without long lead times between very large quantity jobs.

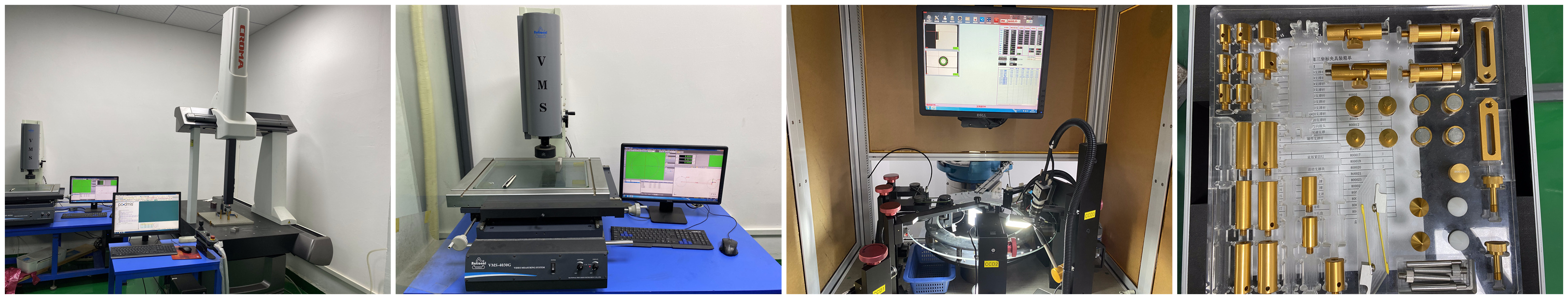

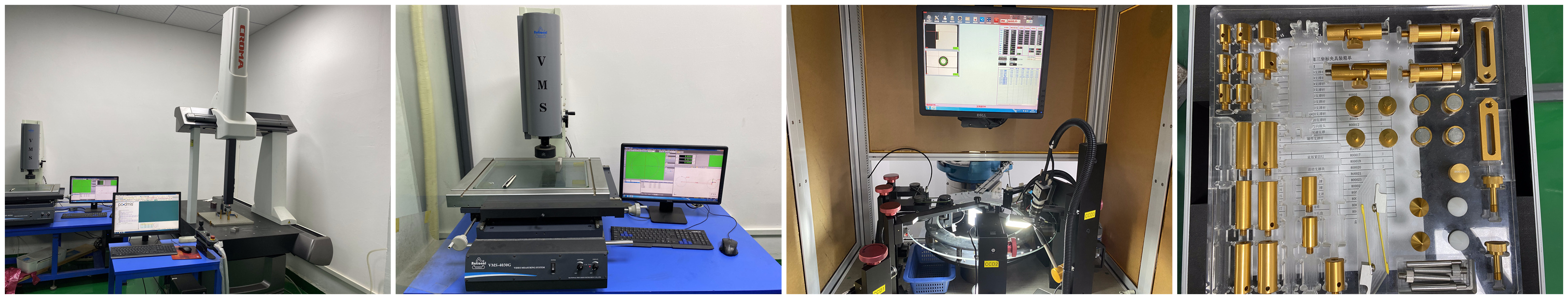

2. Inspection and Quality Capabilities

What's the point of being able to have precision at scale if you don't have any system to confirm it? Our quality systems allow that in every part in a production run of 10 or 10,000,000 will be the same.

In-Process Control: All of our high volume precision machining lines employ Statistical Process Control (SPC) to capture unique trends, to help with real-time failure prevention.

First Article Inspection (FAI): What we do for you includes 3D comparison of the first article with your CAD model.

Metrology Lab: Our lab is equipped with CMMs, optical comparators, and surface roughness testers for full dimensional inspections.

Full Traceability: We can provide material certifications and inspection records for every production run, and that's not just for compliance we're serious about quality and traceability for high volume automotive and medical.

Testing and Measurement Equipment

Testing and Measurement Equipment

| No. | Equipment | Brand & Manufactory | Qty | Tolerance / Spec | Purchase Date | Comment |

| 1 | Projector | Wangmin / China | 5 | 0.004mm | 2018.06 | Travel: 300*200mm |

| 2 | CMM | Hexagon / Global | 1 | 0.002mm | 2018.11 | Travel: 600*800*600mm |

| 3 | Gear Rolling Tester | Hāliàng / China | 1 |

| 2019.1 |

|

| 4 | Gear Measuring Center | Jinda / China | 1 |

| 2019.1 |

|

| 5 | CCD Inspection Machine | Ruike / China | 1 |

| 2021.5 | 5 HD cameras (1x12MP, 4x1.3MP) |

| 6 | CCD Inspection Machine | Ruike / China | 1 |

| 2022.5 | Dual laser + 4x12MP HD cameras, height measurement capable |

| 7 | Video Microscope | Oumite / China | 6 |

| 2021.6 | 8MP |

| 8 | Salt Spray Test Chamber | Tianyi / China | 1 |

| 2018.12 |

|

| 9 | UV Aging Test Chamber | Tianyi / China | 1 | ±1°C | 2020.5 | Temp Range: 10°C~70°C |

| 10 | Thermal Shock Test Chamber | Tianyi / China | 1 | ±1°C | 2020.5 | Temp Range: -45°C~70°C |

| 11 | Surface Roughness Tester | Mitutoyo / Japan | 1 |

| 2023.5 |

|

| 12 | Gloss Meter | 3NH / China | 1 |

| 2020.1 |

|

| 13 | Color Difference Meter | Shenzhen Gaoxin / China | 1 |

| 2023.4 |

|

| 14 | Standard Light Booth | 3NH / China | 1 |

| 2020.1 |

|

| 15 | RCA Abrasion Tester | Deka / China | 1 |

| 2020.6 |

|

| 16 | Electromechanical Test Stand | Shanghai Siwei / China | 1 |

| 2020.7 |

|

3. Production Management and Control

Let us manage your complexity, you don't have to. Our digital backbone is designed to make all the complexity of managing your very large batch CNC production error free, every time.

Integrated MES/ERP System - allows us to provide you with with instant insights into your scheduling, job status, and material availability from quote to delivery.

Lean Flow Manufacturing - our facility is organized for optimal material flow minimizing work in progress (WIP) and lead times.

Supplier Collaboration - we support Just-In-Time (JIT) and Just-in-sequence (JIS) delivery methods and can act a trusted extension of your organization.

4. Cost and Efficiency Control

Using us for your high volume machining should provide you with a lower total cost, and here is how we are able to do that:

Value Engineering: our Engineers will evaluate your design and provide comments where we believe we could minimize machining effort and alleviate wasted material costs.

Efficient Tooling:Latest carbide and advanced coatings to maximize feed rates, engagement rates, and tool life.

Economies of Scale: Our size in relation to our supply chain means we having pricing leverage with our suppliers and guaranteed supply to your project.

5. Comprehensive Service Capabilities

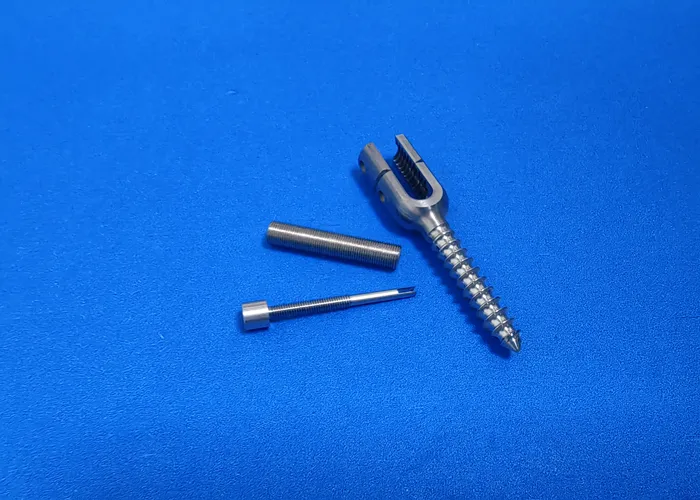

We have an end-to-end solution to assist in the simplification of your supply chain.

Secondary operations: we have established partner networks of vetted trusted experts in anodizing, plating, heat treatments, and finishing.

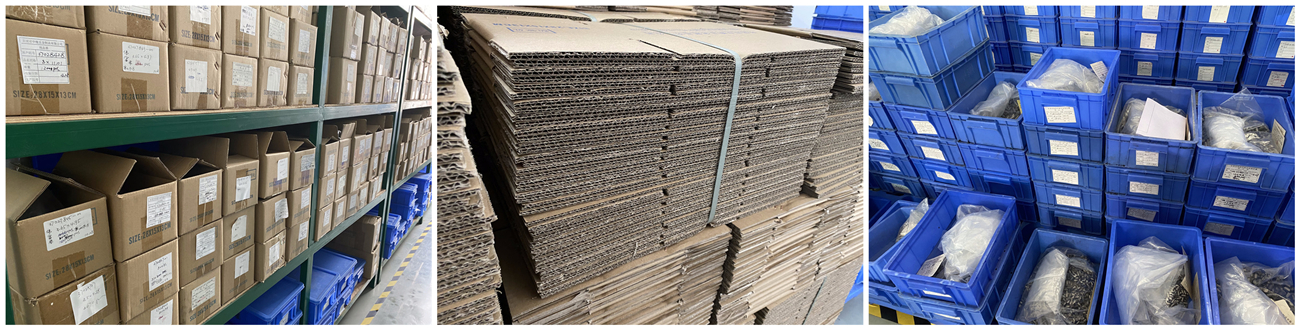

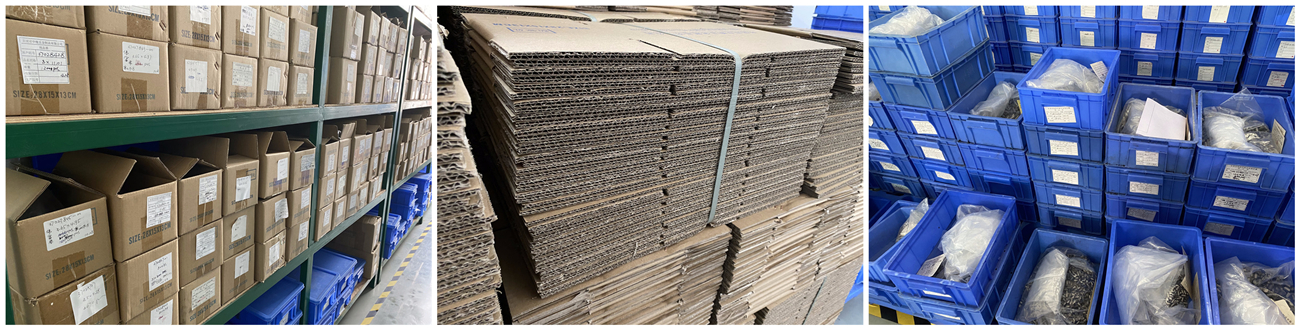

Assembly and kitting: we are available to provide limited assembly and packing for our clients and can provide complete subassemblies for you to your production line.

Technical Partner: our engineering team undertakes expert analysis of your component to ensure you take important steps in ensuring your product is high volume production ready for cost-effective manufacturing right from Day 1.

Why this this makes us your ideal partner

This entire ecosystem of technologies, processes, and people is why we are a high volume contract manufacturing leader. By outsourcing high volume machining to Falcon, you become relieved of a supplier status, to a truly vested status to lower your costs, and improve your quality and protect your supply chain.

Want to feel the Falcon difference?

[Request a Quote for Your High Volume Project]

Testing and Measurement Equipment

Testing and Measurement Equipment