As a trusted surgical device components manufacturer and partner, Falcon CNC Swiss provides precision machining surgical parts and diagnostic device components machining under ISO 13485 standards.. We manufacture critical surgical instrument parts used for surgical instruments, and diagnostic devices. We manufacture components for instruments and devices that must meet ISO 13485 quality system requirements and strive for the highest precision, biocompatible materials, and lowest quality objectives that meet expectations of the medical technology industry. We manufacture components that direct medical professionals to provide patients safe and effective care whether it be through the surgical instruments used to perform life-saving procedures, or devices used to diagnose a patients condition, it is certain that a component from Falcon was used to create and facilitate that patient care.

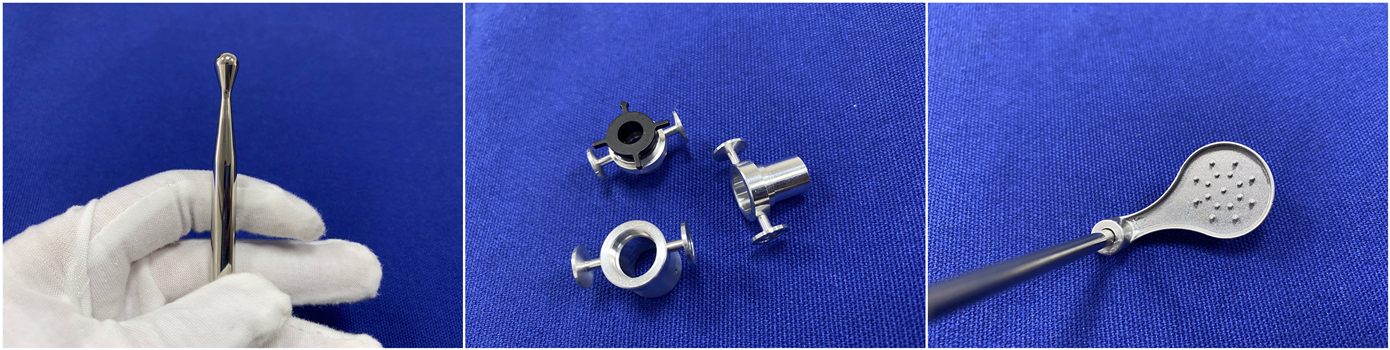

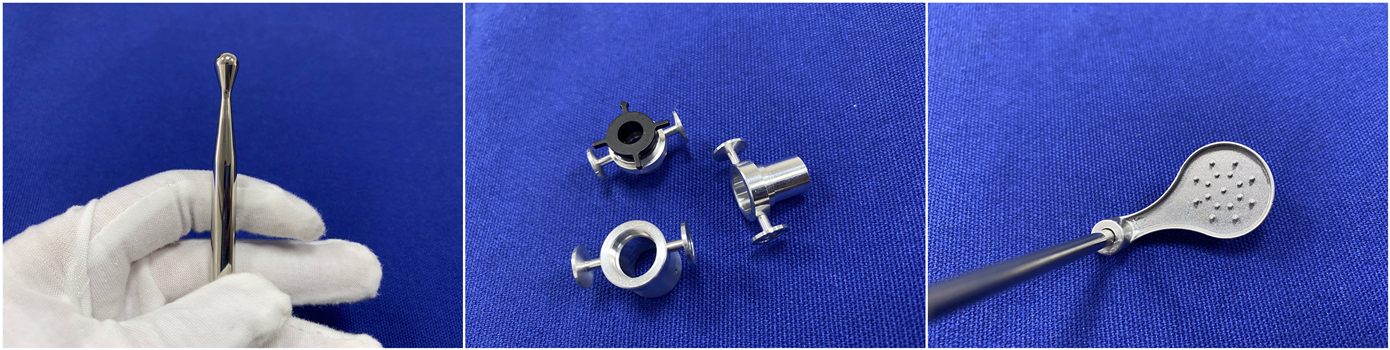

Components for Minimally Invasive & Robotic Surgery

In the recent past many procedures are shifting to minimally invasive procedures that use surgical instruments that require precision and reliability greater than it has needed to be. For this to happen, we at Falcon excel at making intricate and complex miniature components.

Laparoscopic & Endoscopic Instruments

Instrument Shafts & Tubes: Long, small-diameter tubes manufactured with precision swiss machining service, which must maintain perfect straightness and consistence of the internal channel, for more surgical instruments that I can count.

Jaws & Articulating Components: Intricate and complex miniature components for graspers, forceps, and scissors provide fine and precise motion and control at the surgical work space.

Handle Mechanisms: Developing ergonomic component and mechanism part for surgical hand tools provides tactile feedback to surgeon to provide piece of mind to engage their skill in surgery.

Surgical Robotics

Robotic End Effectors: High precision and reliable components for robotic surgical arms and instruments, where robotic surgical options are more accurate and consistant.

Sensor Housings: Miniature protective enclosure for force and vision sensors that protects critical electronics in sterile working conditions.

Drive System Components: Precision gears and mechanisms for a robotic system that provides smooth accurate actuator motion.

Diagnostic & Imaging Device Components

For reliable diagnostic equipment, it starts with manufacturing good parts in diagnostic equipment. We manufacture the components to give reliability and performance for a diagnostic device.

Diagnostic Instrumentation

Precision Machining Medical Housings & CNC Machining Medical Enclosures: Medical device housings machining that must meet the requirements of extremely strict aesthetic and functional performance such as housings for patient-safety instruments.

Fluidic Components: Precision manufactured fluidic components used in blood analyzers and lab automation where there are elaborate micro-channels with tight tolerances.

Optical Mounts: Precision components with respect to the known optical tolerances regarding lenses and sensors in imaging systems where stable and accurate positioning is critical.

Patient Monitoring & Treatment

Connectors & Interfaces: Medical-grade components used on patient monitors, infusion pumps, and ventilators that need secure connectors.

Wearable Sensor Housings: Biocompatible enclosures that come into contact with human skin for some devices used for continual monitoring.

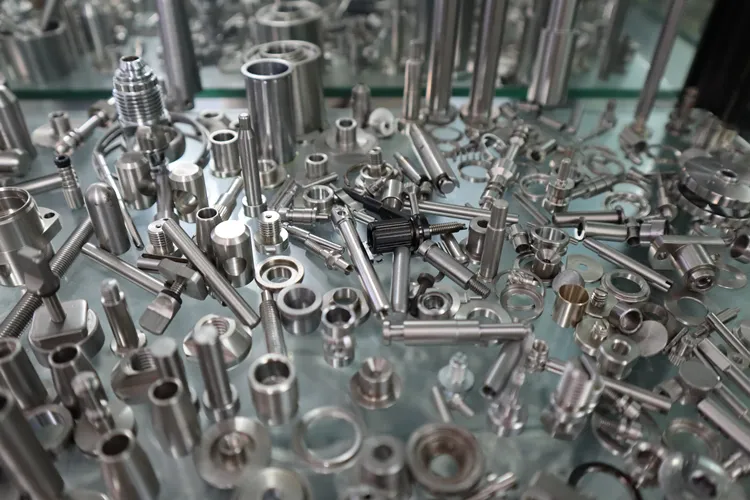

Our Medical Device Manufacturing Expertise

We know that medical components have to be manufactured with precision however, they must be manufactured with extreme quality and compliance.

Biocompatible Materials Mastery

We machine material using certified medical materials and standards.

Surgical Stainless Steel CNC Machining (304, 316, 316L VM): with respect to corrosion resistance and durability in surgical instruments safety and performance

Titanium (Grade 5, Grade 23): with unprecedent strength to weight ratio and biocompatibility for implantable components

Medical Plastics (PEEK, PEI, PPSU): that have very special properties include radiolucency, electrical insulation, and chemical resistance

Aluminum Alloys: used generally for the structural components of diagnostic device, needs to be a material that is light weight.

Medical-Grade Finishing

Electropolishing: Used to provide the component an improved corrosion resistance, deburring, and cleaning of stainless steel components.

Passivation: Used to improve the corrosion resistance of stainless steel, where an acid is used as a chemical treatment.

Bead Blasting & Mechanical Polishing: Used to achieve a desired aesthetic appearance or functional surface requirements.

Rigorous Quality Management

ISO 13485 Certified: Our quality system has been designed to for medical devices.

Full Material Traceability: We provide certification of the materials providing complete traceability of materials from raw material to finished part.

Validated Processes: All manufacture processes which are critical to the component have been validated to present expected results.

Cleanroom Packaging: Parts are cleaned and packaged within controlled establishments to prevent contamination.

Explore more about our capabilities of our medical precision CNC machining →

Why Partner with Falcon CNC Swiss?

Regulatory Knowledge

Design for Manufacturability

Variable Volume Production

Surely you will relinquish your critical medical components to a manufacturer that knows the stakes. Not everyone can provide precision at life-saving exigence standards like Falcon CNC Swiss. Request Your Confidential Quote for Custom Surgical Instrument Machining and Diagnostic Components Today!

Frequently Asked Questions (FAQ)

Are you ISO 13485 certified?

Yes, we specialize in machining components for Medical Devices to ISO 13485 standards. The ISO 13485 certification allows us to meet and demonstrate to medical device manufacturing partners, a commitment to the highest quality standards in medical device manufacturing processes.

What documentation do you provide for medical components?

We generally will include material certifications, certificates of conformity, first article inspection reports and, if required by the medical device, complete device history records.

Can you machine components for implantable devices?

Yes, we can machine components for implantable devices from biocompatible materials, such as titanium, and stainless steels. There are protocols and documentation that need to be followed for compliance in this area.

How do you protect cleanliness and continuity?

We have validated cleaning process and can package parts in cleanroom environments to ensure parts are free of contaminates and prepared for sterilization.