Introduction: Why Aluminum is a Fantastic Choice for Swiss-Type Lathes

In high-volume and tightly-toleranced steps along the production cycle, we are often met with two questions: “Is aluminum good for Swiss machining” and “Are there times when to choose Swiss machining aluminum vs CNC turning?” Here at Falcon CNC Swiss, we Swiss machine aluminum on our lathes every day. The answer is quite clear: aluminum is good—but often it is more than good. It’s the best way to produce small, complicated components with the best efficiency.

In this guide, we will dig into applications of aluminum alloys for Swiss screw machining and go beyond the specifications into the engineering and practical aspects of why and when certain precision Swiss machining aluminum makes so much sense. Whether you’re dealing with small aluminum parts Swiss machining is made for or considering custom aluminum swiss machining for a new project, this guide provides a solid basis of knowledge.

The Fundamentals: How Swiss Screw Machining Works with Aluminum

Swiss-type lathes—the machines that fabricate aluminum Swiss screw machining parts—are sometimes called Swiss lathes as well. The characteristic feature of Swiss-type lathes, also called Swiss lathes, is that rather than utilizing a chuck to hold workpieces during machining, the bar stock is fed through into a bushing and the workpiece is turned from a workpiece supported only from the cutting tools via that guide bushing. This supports the machined piece closely to the cutting tools, minimizing deflection and vibration as work is done to long, slim parts that are characteristic of Swiss turning aluminum parts.

When used to machine aluminum, Swisstype lathes have certain advantages and benefits, including:

Stability: Because bar stock is supported over the way by the bushing, aluminum’s softer structure can be aggressively machined without generating chatter, creating better finishes.

Complexity in One Setup: Because multiple axes and live tooling are available on Swiss machines, it’s possible to complete the machining of complex aluminum Swiss screw machining parts—off-center holes, milling, cross-hatching—in one step.

Efficiency: Because the bar can be continuously fed, Swiss machines are suited to lots of identical pieces with little need for operator intervention.

Benefits of Swiss Machining aluminum for components

Opting for Swiss machining aluminum over other processes provides a compromise between precision, efficiency, and capability.

1. Extreme Precision for Small and Intricate Features

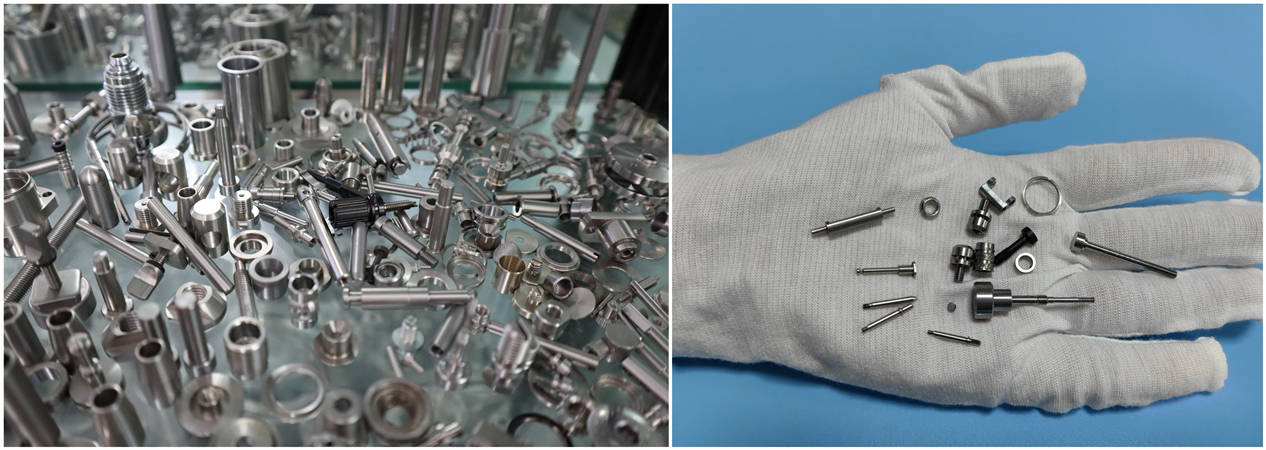

This is the most significant benefit. For micro aluminum parts Swiss machining is the go-to process. The inherent rigidity of the Swiss lathe means tolerances of ±0.0005” (0.0127mm) are held routinely, even on parts under 1mm in diameter. This is critical for connector components, cutting tools for surgery, and miniaturized aerospace actuators.

2. Improved Surface Finish and Quality

The combination of high spindle speeds (which are good for aluminum), sharp tooling, and little deflection during workholding gives superb surface finishes as the parts come off the machine. This means less or no requirement for second-operation finishing, which leads to cost and time savings per part.

3. Economical Production of Small Parts

For small aluminum parts Swiss machining is incredibly efficient. The fact that several different operations can be completed in one chucking greatly reduces the cycle time and combined with aluminum’s excellent machinability, complex parts can be produced economically at high volume.

4. Less Waste of Material

Swiss machines are quite precise in their use of materials. Because tools are close to the collet, the “bar end” that must be scrapped is small. When expensive aluminum alloys are used this conserves material costs.

Swiss Machining Aluminum vs. CNC Turning: An Engineer’s Perspective

Making this call is critical. Here’s the fine print to inform your choice:

| Feature | Swiss Machining (for Aluminum) | CNC Turning (for Aluminum) |

| Part Geometry | Best for: Long, slender parts (L/D > 3), complex parts requiring back-working, off-center features, and intricate milling/drilling in one setup. | Best for: Shorter, stubbier parts, simpler 2-axis contours, and parts where all features are radially symmetrical. |

| Precision & Tolerances | Exceptional. Superior for holding tight tolerances on long, thin parts due to guide bushing support. Ideal for precision Swiss machining aluminum. | Very Good, but can struggle with deflection on high L/D ratio parts, requiring slower feeds or secondary operations. |

| Multi-Tasking Capability | Integrated. Designed for complete part machining in one cycle with live tooling and secondary spindles. | Often Limited. Primarily a turning process. Milling/drilling may require a separate CNC milling machine and a second setup. |

| Production Volume | Excellent for High Volume. Once set up, it runs with minimal intervention, perfect for orders of thousands to millions of parts. | Flexible. Efficient for both medium and high-volume runs, but may be slower for highly complex parts. |

| Cost-Effectiveness | Higher initial setup cost, lower per-part cost at high volumes for complex parts. The "value" is in completed part output. | Lower initial setup, but per-part cost can be higher for complex parts requiring multiple machines/setups. |

The Falcon CNC Swiss Verdict: Most of the time—especially if your part is small, slender, or otherwise complex, or if you wish to machine the whole thing in a single run—Swiss lathe machining aluminum is the right call. For more basic, chunkier bits, conventional turning will do.

Best Alloy Aluminum Alloys for Swiss Machining

The world of Swiss screw machining is not one where just any old aluminum will do. Just like the metals machining themselves, choosing the right alloy is crucial for CNC Swiss screw machining. Here are some of the most common:

6061-T6: The most common all-purpose alloy. Offer a great balance of strength, machinability, corrosion resistance and weldability. Our default for a huge number of custom aluminum Swiss machining prototypes and components.

7075-T6: The high-strength choice. Commonly referred to as “aircraft aluminum” it is much stronger than 6061 but somewhat harder to machine and poorer on the corrosion resistance front. Ideal for high load structural Swiss turning aluminum parts.

2024-T3/4: Another high-strength alloy with great fatigue resistance. Machines well but poor corrosion resistance often requiring anodizing or painting. Used in aerospace fasteners.

Aluminum 5052: A non-heat-treatable alloy with excellent corrosion resistance, especially in marine environments. Good formability but lower strength. Best for specific environmental applications.

Free-Machining Alloys (ex 2011-T3): Specifically designed for machining. Additives create small, brittle chips, extending tool life and improving surface finish.The premier choice for the most demanding, high-volume aluminum Swiss screw machining projects.

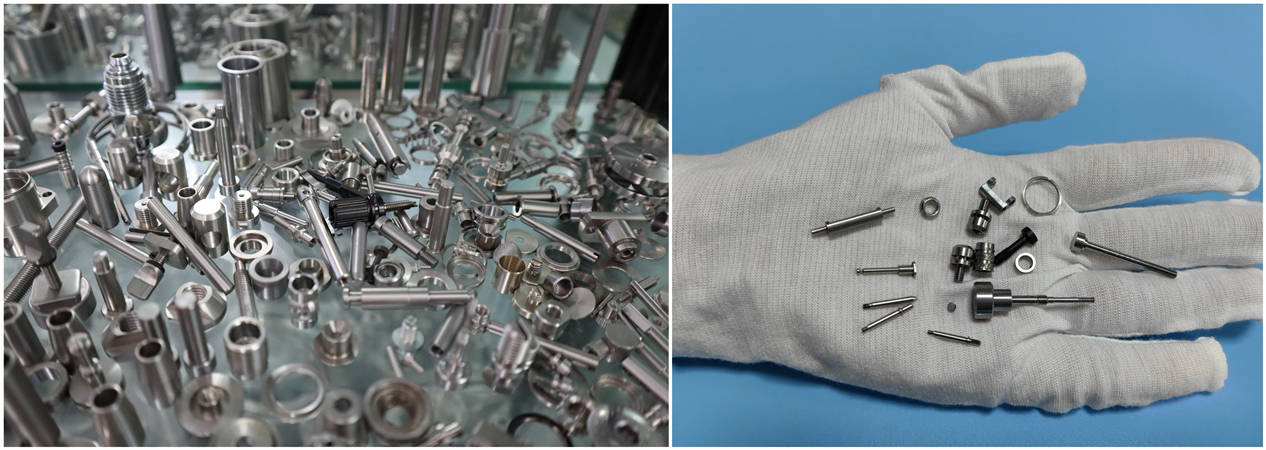

Key Applications for Swiss-Machined Aluminum

Few processes can match the abilities of Swiss machining aluminum, which shows up in the following industries:

Medical & Dental: Surgical instrument handles, endoscopic parts, dental implant abutments, and connector pins. The biocompatibility, precision, and cleanability of aluminum—two reasons why so many surgical instruments feature aluminum handles—play a big role.

Aerospace & Defense: Sensor housings, shoulder-mounted connector bodies, waveguide components, and miniature actuators. The strength-to-weight ratio of alloys like 7075, combined with Swiss precision, pays off in spades.

Electronics & Semiconductors: Heat sink pins and connector housings, RF shielding components, and probe tips for test sockets. Producing the small features found in semiconductors is Swiss machining’s forte.

Automotive: Fuel injector components, sensor housings, transmission pins, and parts for advanced lightening systems. In short, Swiss machining meets the automotive high-volume and precision standards.

Design for Manufacturing (DFM) Tips for Swiss-Machined Aluminum

To help you optimize your part for cost, speed and quality, our engineers share these tips:

Be mindful of Length-to Diameter (L/D) ratios: Swiss machines work best when the L/D ratio is greater than 3. If your part is very short, check with your manufacturer to see if it can be “chained” in multiples along the bar stock.

Specify tolerances wisely: Use critical tolerances only as function warrants—each callout for “±0.0001” adds to cost. Often a standard tolerance of ±0.001” is adequate for many features.

Consider chip evacuation: Design features so that chips will clear easily. Avoid deep, small diameter blind holes that can fill with stringy aluminum chips.

Use standard tooling: Inside corner radii should equal standard cutter sizes (ie. 0.010”, 0.015”, 0.020”). Custom tooling will be more costly.

Plan for finishing: If Anodizing is required, specify, and we can machine to the correct dimensions to allow for coating thickness.

Aluminum Components Partnering with Falcon CNC Swiss

We don’t just run machines; we engineer outcomes at Falcon CNC Swiss. Each Swiss machining aluminum project benefits from a wealth of experience in process engineering, full buy-off and lease buy-off DFM analysis, and a commitment to the rigor of process control, all informed by a deep understanding of the material science of each alloy we process. Here’s just a brief look at what you’ll benefit from when you partner with Falcon CNC Swiss for your precision Swiss machining aluminum needs:

Engineering Analysis Process Gates: Every single aluminum project is reviewed for design for manufacturing issues, presciently addressing performance parameters and material cost nuances before we ever throw down the first toolpath of code.

Full-Traceability & Quality Ownership: From validation material certifications to shop-floor inspection, our entire process allows us to guarantee that each batch of Swiss turning aluminum parts is exactly what you need.

Single Point of Contact Ownership: From the initial design details to prototypes right through full-scale productions runs, you have a single point of contact ensuring that your project is fully understood and runs smoothly and punctually.

If you have prototyping for micro aluminum parts that can benefit from the impact of Swiss machining, or if you have a production run to scale up and need reliable Swiss machining services, we employ a comprehensive service that assures precision and efficiency in part production.

Want to talk about what benefits await you in your next Swiss machined aluminum part?

Reach out to our engineering team today and request a design review and quote to see what our Swiss machining aluminum capabilities can do for you. Take a look at our dedicated capabilities for aluminum precision machining for basic details about our specific processes and equipment.