In the rapidly changing landscape of 5G and data center markets, where performance, reliability, and thermal efficiency are paramount, we deliver precision CNC machined parts that meet the stringent requirements of world-leading telecommunications equipment manufacturers and data center hardware providers and we are uniquely positioned to support signal integrity, thermal dissipation, and EMI protection - always.

Enabling Next-Generation Communications

The launch of new fiber optic and 5G networks require components that have higher frequencies and higher power densities than before and we deliver precision parts that enable these technical capabilities.

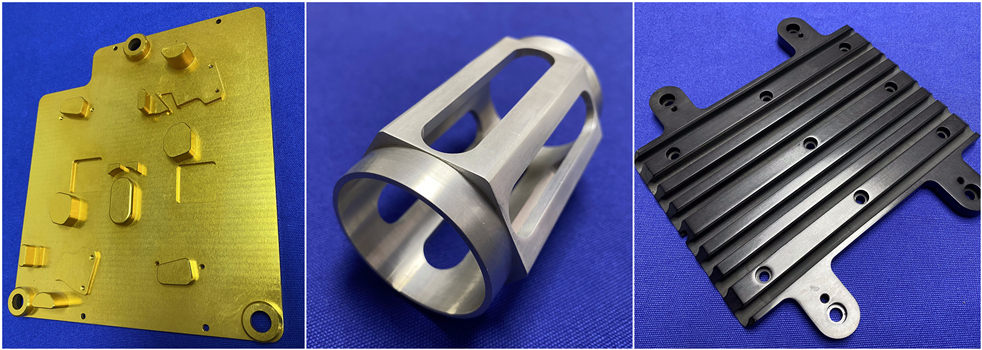

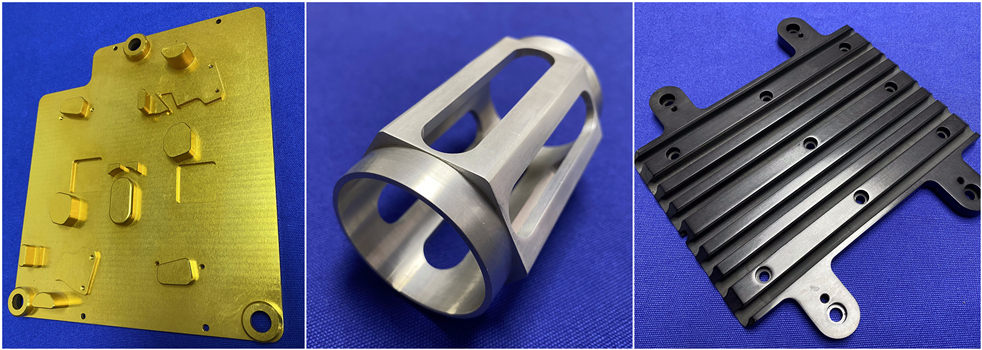

5G Equipment Enclosure Machining and RF Components

Antenna Systems: Antenna housing and radome components machined with the dimensional stability and environmental sealing required for precision antenna systems.

RF & Waveguide Components: Waveguide machining components for filters, diplexers, and communications base station antennas with the finish quality and dimensional accuracies that maintain signal integrity.

Base Station Equipment: Base station structural components, structural components, brackets, and housings of base station equipment that provide rigidity and protection for electronics.

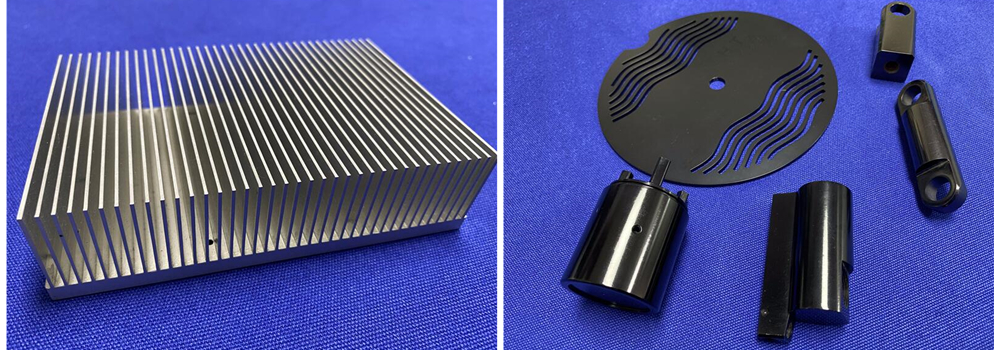

Fiber Optic Network Components

Fiber Enclosures / Cassettes: Fiber optic enclosures machined to spec for ONTs, OLTs, and distribution frames incorporating precision alignment features for connectors.

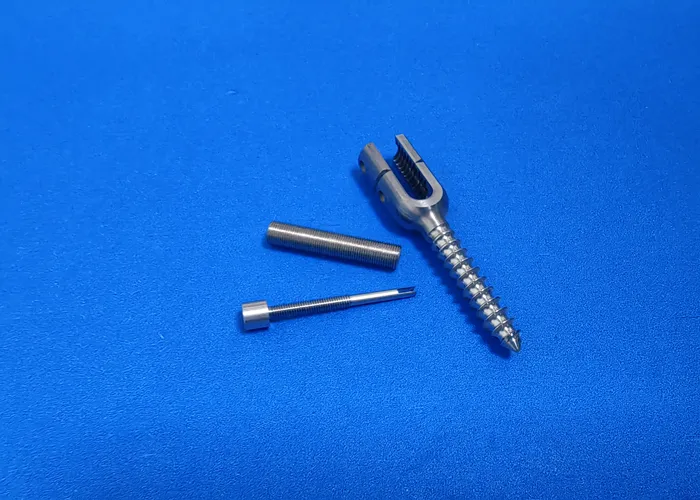

Optical Transceiver Components: High-accuracy machined components for optical transceivers including housings, lens barrels and inner ferrules.

Splice Trays & Adapter Plates: Fiber management components designed to maintain organization and protect weak fiber splices.

learn more about our CNC capabilities or high volume Swiss machining services to meet your requests!

Powering The Data Center Ecosystem

Data centers demand hardware components that deliver density, reliability, and efficiency. We manufacture the components.

Server Heatsinks & Enclosure Components

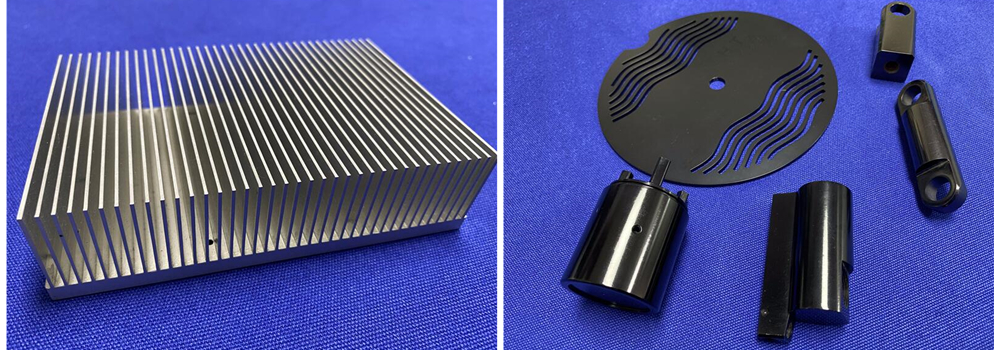

Server Heat Sinks: High-performance heat sinks can have complex fin structures and we are able to machine complex geometries to maximize dissipation in tight spaces for CPUs, GPUs and ASICs.

Server Rails & Chassis: Precision machined server rails with structural chassis components purposefully engineered to provide resilience for roll-in/out and excessive density.

Backplanes & Connectors: Backplane connectors require components machined to maintain precise alignment in order to ensure the fastest throughput possible across multiple server blades.

Networking & Switch Components

Network Switch Chassis: Structural enclosures and housing machined from materials that will provide EMI/RFI shielding for routers, and switches.

Cooling Solutions: Cold plate manufacturing is becoming more essential with liquid cooling systems increasingly being implemented in high-performance computing.

Our Capabilities in Telecom & Data Centers

We utilize precision manufacturing capabilities, and an understanding of the unique industry needs.

Telecom Heatsink Manufacturing & Thermal Solutions

We engineer and manufacture cutting-edge thermal management solutions using materials with high thermal conductivity, like aluminum and copper alloys, to dissipate heat efficiently from high-powered components.

EMI/RFI Shielding Solutions

High-Volume Precision

Materials We Work With

Aluminum 6061 & 7075: Excellent strength-to-weight ratio and conductivity best serves heat sinks and enclosures.

Copper Alloys (C11000, C14500): Excellent thermal conductivity best serves cooling applications.

Zinc Alloys: Excellent properties in EMI shielding applications.

Stainless Steel: Where strength and corrosion resistance are required in structural components.

Why Work with Falcon CNC Swiss?

Industrial Knowledge

End-to-End Support

Quality & Reliability

Keep the world connected with performance and reliability built into the components. Work with Falcon CNC Swiss for your important telecom and data center needs.Request Your Free Quote for 5G Base Station CNC Parts and Enclosures Today!

Frequently Asked Questions (FAQ)

How do you make sure components address the EMI shielding aspects?

We use the right materials selected (like zinc alloys), achieve tight tolerances to ensure mated surfaces fit seamlessly, and we can use specialized finishes to help address EMI/RFI shielding.

What tolerances are critical to waveguide components?

Waveguide components often require very tight tolerances (typically ±0.0005" or better) and very fine surface finishes to support high-frequency performance and reduced signal loss.

Can you help optimize a heat sink design for manufacturability?

Absolutely! Our engineering team gives Design for Manufacturability (DFM) feedback on the design itself to help optimize the fin, base thickness, and design as a whole to maximize thermal performance with the associated cost and time it takes to machine.

Do you have anodizing or other protective finishes?

Yes. We offer hardcoat anodizing to improve wear, chemical film (Alodine) for corrosion protection, and electroless nickel plating for a variety of plausible functional requirements.