The automotive industry is currently undergoing a seismic shift prompted primarily by the transition to electric vehicles (EVs), autonomous vehicles, and higher efficiencies. At Falcon CNC Swiss, we are at the forefront of the paradigm shift within the automotive supply chain, as we provide high precision automotive machining services for not only more traditional CNC machining car parts but also for the next generation of electric vehicle parts. As a leading ISO 916949 certified manufacturer, we can deliver the quality, reliability, and volume of production that Tier 1 and Tier 2 suppliers require.

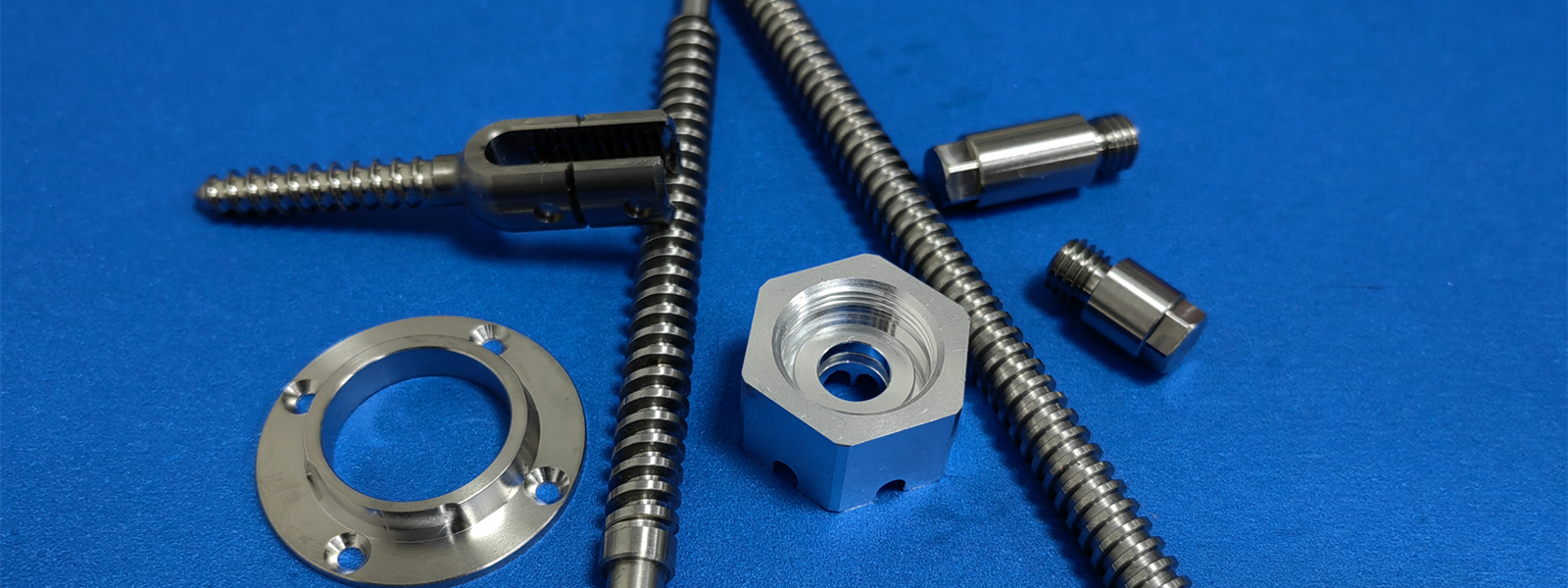

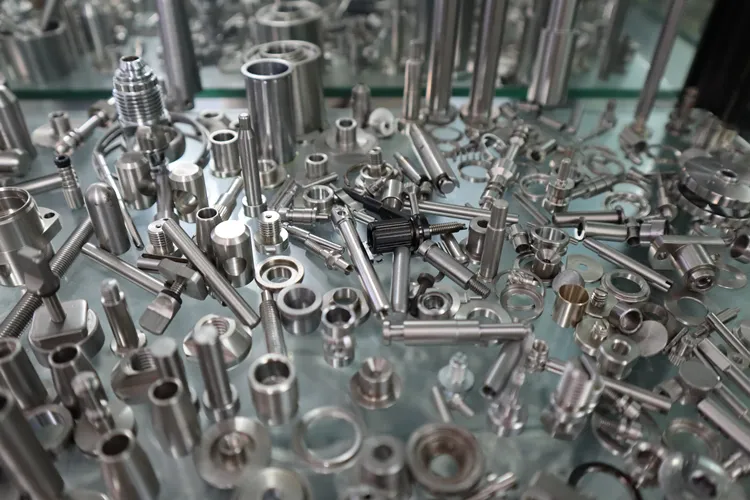

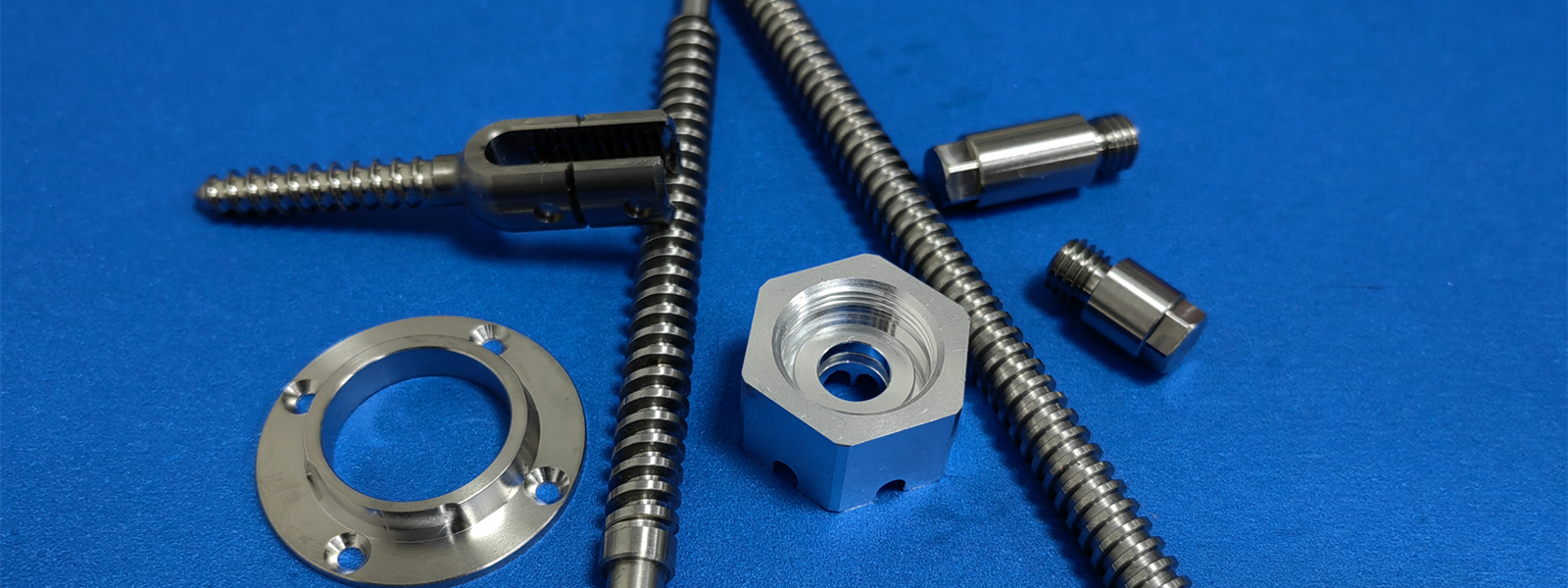

As a specialized custom car parts manufacturer and full-service CNC automotive machine shop, Falcon CNC Swiss is a premium provider of automation parts machining for automotive-grade or high-performance vehicle and Original Equipment Manufacturer (OEM) automotive applications. We specialize in custom CNC car parts in Swiss CNC machining, multi-axis turning, and traditional CNC milling, which are used to produce high-tolerance car components with precision engineering using difficult-to-machine metals and engineering plastics. We specialize in custom CNC car parts, engine and brake system components, and special machined auto parts. We provide the highest quality, and tight tolerances and some of the fastest lead times in the country for automotive customers across the globe.

Custom Automotive Machining & EV Parts Manufacturing

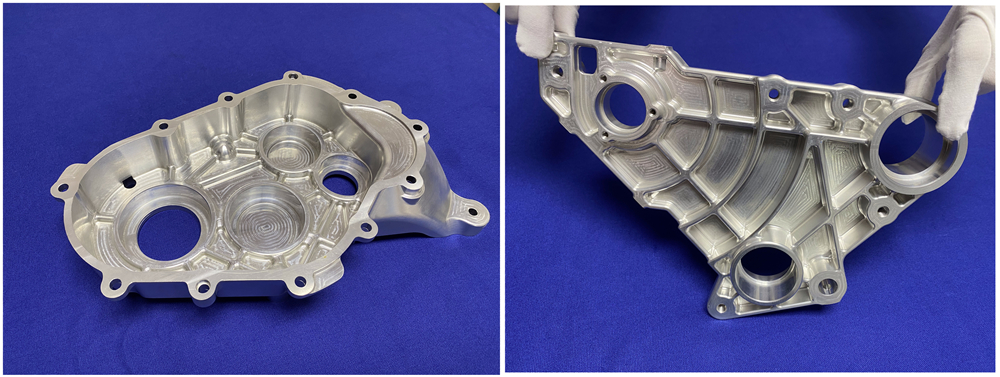

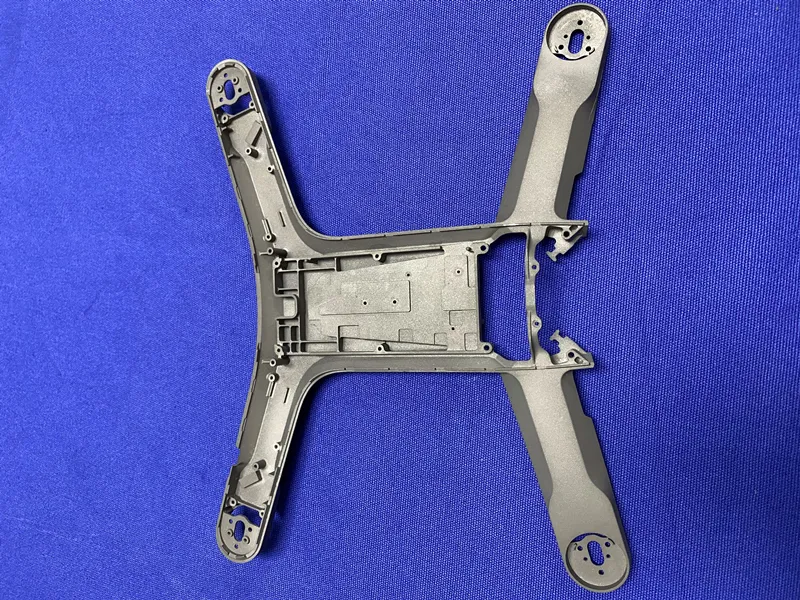

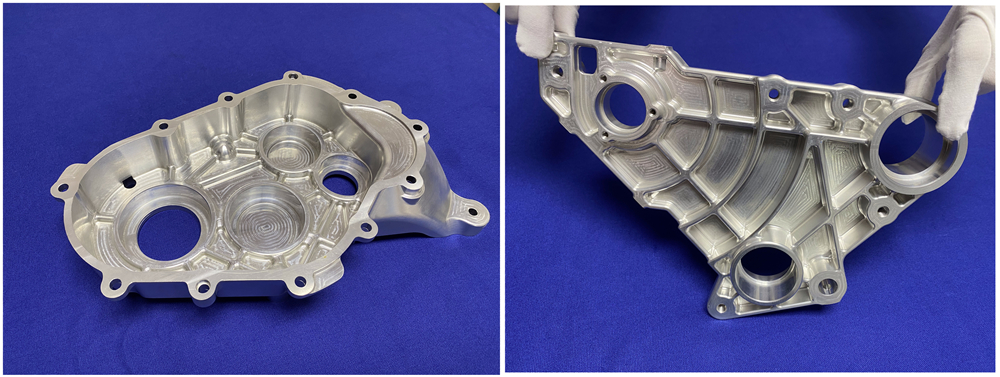

The evolution to electric powertrains will require a new angle on precision machining custom auto parts. Components of an EV typically require tight tolerancing and shipped at low variation even with very complex geometries and exotic materials in terms of application within automotive thermal management, power electronics, and sensors. Our precision Swiss CNC turn-mill machining services, and CNC multi-axis machining capabilities are well suited for manufacturing these higher valued components for the EV sector with the expectations of consistency and scale for the automotive industry.

EV Components We Machine

Battery System Components: Cases, battery connectors, bus bars, cooling plates.

Power Electronics: Cases for inverters, cases for converters, cases for ECU (Electronic Control Unit) components.

Electric Drive Units: Lightweight shafts, spacers, sensor rings.

Thermal Management Systems: Cooling systems components critical to the EV battery performance.

Our Custom Car Parts Capabilities

Swiss CNC machined custom car parts are our strength. We manufacture automotive components, including engine shafts, valve bodies, fuel connectors, and brake calipers, which require high repeatability and surface finishes that must be met for performance and safety systems in automotive engines.

We use advanced ultra-precision CNC Swiss type lathes to produce complex automotive components with tolerances down to ±0.002 mm for mass automotive production. We have experience producing components for combustion engine parts and electric vehicle (EV) drivetrains.

Swiss Machined Automotive Components

| Category | Typical Components |

| Engine System | Valve stems, timing pins, throttle shafts, EGR valve stems |

| Fuel System | Hydraulic valves and components, high-pressure, fuel rail spacers, injector retainer rings |

| Transmission and Drivetrain | Transmission shaft pins, bushings, crankshaft oil restrictors |

| Brake System | Brake caliper pistons, ABS sensor housings |

| Emission and Control | Oil control valve bodies, solenoid valve plungers |

| Electrical and Sensors | Ignition system pins, electrical contacts and screws, battery terminal posts, sensor housings |

| Steering and Safety | Steering shaft sleeves, airbag detonator pins

|

To learn more about our work experience with precision Swiss machining services, and in difficult industries such as automotive or medical.

Aluminum, Steel, and Titanium Automotive Components

We offer precision machining of automotive-grade components in various materials, including:

- Aluminum 6061-T6 / 7075-T6: Ideal for lightweight components like brackets, housing, and coolant or heat exchangers.

- Stainless Steel (304, 316, 17-4 PH): High-strength parts, including exhaust manifolds and drive shafts.

- Titanium (Ti6Al4V): High pec, high-performance, racing applications, where acceptable strength and weight value is critical.

- Engineering Plastics (POM, Nylon, PEEK): Ideal for insulating components in hybrid applications.

we know how to select the right material for the job based on application requirements for durability, resistance to corrosion, and weight factors. Looking for more about the titanium machining or plastic CNC parts we manufacture? We do both.

CNC Auto Parts Manufacturer & Factory in China

Falcon CNC Swiss is globally recognized as an excellent and trusted CNC car parts manufacturer and factory for Tier 1 and Tier 2 customers in the automotive industry. Our factory in Dongguan is certified to ISO 9001 specifications, allowing us to deliver consistent quality at scale, no matter the order size.

We offer complete CNC auto part services, from design review, prototyping, to mass production, and surface finishing. Our engineering team ensures all parts meet your expectations for precision machined auto components for aftermarket enhancements and Original Equipment Manufacturing supply chain.

Let a trusted and experienced Swiss machine shop safely handle your automotive grade production and export logistics.

Quality Assurance, IATF 16949 Certification & High Volume Capabilities

At Falcon CNC Swiss, we believe that quality and reliability pose the greatest challenges in the automotive industry.

Quality Assurance (QA)

Falcon CNC Swiss has a robust QA system to ensure that every automotive parts have been inspected throughout the production process. We utilize sophisticated measurement equipment including CMM (Coordinate Measuring Machines), surface roughness testers, and 100% in-line inspections to ensure tight tolerances and consistent quality of part. Our quality engineers work with production to ensure on-time delivery of defect-free parts.

IATF 16949 Certification

Falcon CNC Swiss has adopted the internationally recognized IATF 16949 standard, which identifies the quality management system requirements for automotive manufacturers. This certification confirms our commitment to continual improvement, defect prevention, and the reduction of variation and waste along the supply chain. Working with an IATF 16949 certified manufacturer assures you they are meeting OEM standards of both quality and process.

High Volume Production Capabilities

Falcon CNC Swiss has the industry capability to handle high volume automotive machining projects. Our newer CNC Swiss-type machines include automatic bar feeding and multi-spindle for faster cycle times and scalable production. Regardless if you need thousands of annual parts or millions annually Falcon CNC Swiss will deliver quality and on-time delivery to meet your supply chain expectations.

Why Work with Falcon CNC Swiss for Your Auto Parts?

High Volume Production

Due to the high volume needs of automotive manufacturing projects, our CNC Swiss screw machines and automation systems, ensure productivity and uniformity at a competitive price for high volume production runs.

Quality and Precision

Every part needs to deliver. Our tolerances are tight, often with microns of variation, and our inspection regimes involve using CMM for quality adhering to automotive standards and inspections to make sure every part is manufactured to precise specifications for passenger safety.

Expertise on Materials

We can machine the full spectrum of automotive qualified materials, from aluminum and stainless steels for lightweighting to copper alloys for conductive properties and high performance plastics for durability.

Get in Touch

Searching for a reliable CNC auto parts manufacturer or custom automotive machining partner?

No matter what you are looking for, prototypes, small runs, or high volume, we can assist you and support your project with our expertise in CNC machining. Request a free quote now!