Precision is non-negotiable in today’s automotive manufacturing. Cars are getting more advanced, designed more efficiently, and yielding greater amounts of vehicular independence, and every component must deliver unprecedented levels of reliability and performance to fulfill that responsibility. Then enters the world of Swiss machining.

At Falcon CNC Swiss, we focus on using cutting-edge CNC Swiss machining technology to produce precision automotive components. We’ll explore why Swiss machining is becoming the essential manufacturing solution for small companies and large corporations to build the cars of tomorrow.

1. Why Precision is Critical in Automotive Manufacturing Today

Cars are computers on wheels. Advanced driver-assistance systems (ADAS) and electric vehicle (EV) powertrains all depend on components with precision parts. Even the slightest misalignment of an automotive sensor housing, or defect within a drivetrain can lead to disastrous performance and expensive recalls.

Utilizing Swiss machining means that achieving uptight tolerances and extremely complex geometries aren't just a goal, it's standard practice. The reliability, safety, and performance of all automotive systems starts with producing precision parts.

2. How Swiss Machining is Changing Automotive Innovation

Swiss machining isn't just another tool in the tool chest of the machine shops of automotive machining; it’s a game-changer. Here’s why:

Exceptional Tolerances for Critical Components

Applications such as fuel injection components, connector housings for various sensors, and fuels injectors demand micrometer tolerances. These tolerances — as consistent as ±0.0002 inches (0.005 mm) or greater! — can be produced, batch after batch, with Swiss machining.

Perfect for the Toughest, High-Strength Materials

Components of automobiles often demand strong materials like titanium, high-performance alloy, and stainless steel. Swiss lathes are made for these tough materials while holding tight tolerances.

Ideal for High-Volume Production

Swiss machining is great for both small-scale prototyping and large scale production, easily capable of scaling production whether you're evaluating a new design for an EV battery connector or running a hundred parts, or even ten-thousand parts.

Top Surface Finish Capabilities

Smoother surfaces offer more than visual appeal, they reduce friction, increase durability, and improve assembly fits. Swiss machining offers the best surface finish quality straight off the machine.

3. Trending Topics: Swiss Machining and Electric Vehicles (EVs)

Electric vehicles (EVs) aren't just the future, they are here now. In 2023, the global number of EVs sold increased by 35%; therefore, we are fully underway to a future where every major manufacturer will electrify their fleet (source: IEA Global EV Outlook 2024). These technologies will require next-gen components:

Swiss machining is imperative the EV revolution because it can precisely manufacture components that are complex and miniaturized. That's every single component from making a sure a flawless connection is made in the link between two battery brains, to lightweight coordinate brackets to enhance efficiency, we will all be a part of a greater mission in the EV revolution.

4. Examples of Real-World Automotive Components to Consider Using Swiss Machining With

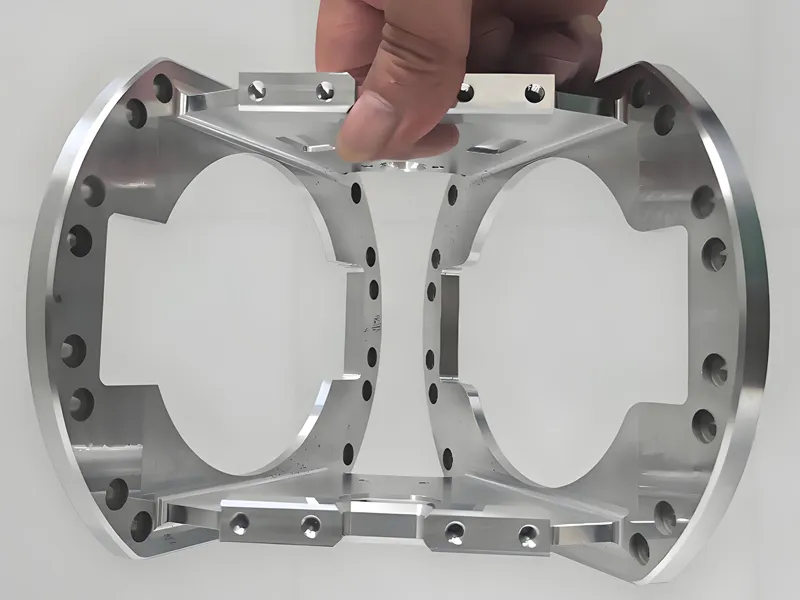

Here at Falcon CNC Swiss, we supply numerous types of precision components in the automotive sector:

Fuel injector components

Parts for ABS brake systems

High-voltage battery connectors

Parts for transmission control systems

Parts for Turbocharger inserts

Motor shafts and advanced sensor housings for EVs

Fasteners and specialty bolts at precision tolerances

We have partnered with various tier 1 and tier 2 automotive suppliers and followed OEM specifications.

5. Why Choose Falcon CNC Swiss for Automotive Projects?

Choosing a machining partner to get your project done is not a decision to take lightly. Choosing Falcon CNC Swiss provides

Experience

Decades of experience producing critical automotive parts for leading automotive manufacturers.

Latest Technology

We have the latest round of Swiss CNC lathes that can hold extreme precision and depth multi-axis capabilities for complex parts.

Materials

We can machine the most durable materials used in today's vehicles from stainless steel to aerospace-grade materials.

Quality Assurance

Thorough inspection processes and machine capabilities provide CMM analysis, optical measurement, and total traceability documentation.

When you partner with Falcon CNC Swiss, you now have another supplier that cares about precision, reliability, and on-time delivery as much as you do.

6. Key Takeaways: Precision that gets you moving

The automotive industry is continuously changing and is racing forward at full speed. Only the manufacturing partners that can responsibly assure dependable track record of precision, will continue to impact the automotive industry. Whether it's if you are developing the next EV, or more advanced technologies that could potentially save lives in critical conditions, Swiss machining gets you that one step closer to win. Overall, it's time to see for yourself how Swiss machining can benefit the vehicle you and manufacture.

Are you ready to get the next project you are working on moving and gain the efficiency you need, the precision with Falcon CNC Swiss?

�� Contact Falcon CNC Swiss today to get your next automotive precision video automotive in motion!