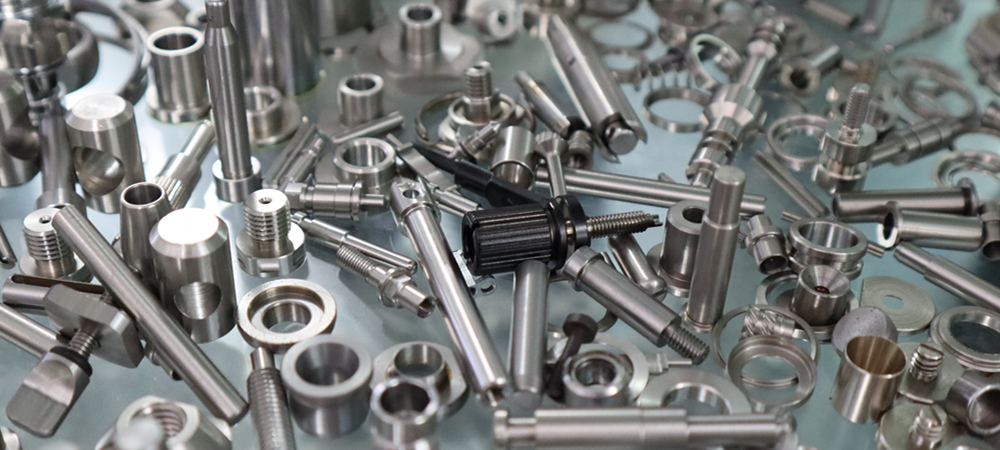

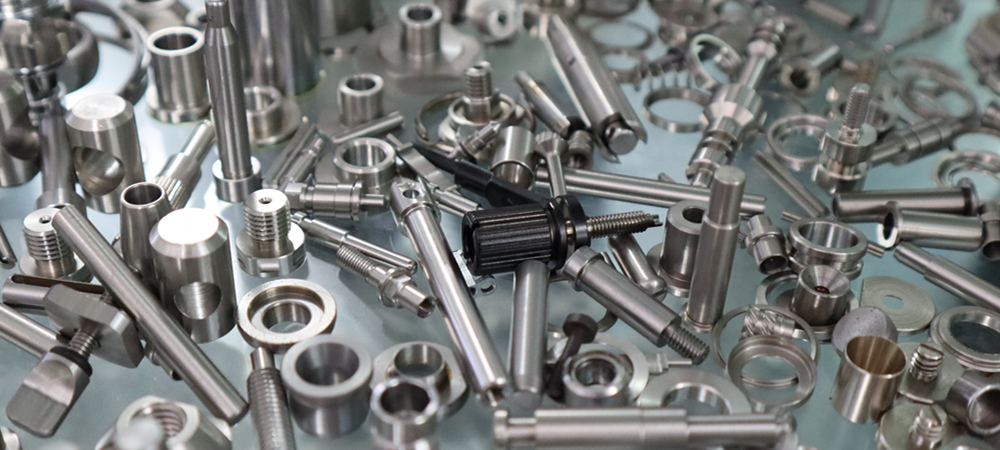

Taper dowel pins and threaded dowel pins are prevalent in precision mechanical assemblies wherever accurate or repeatable re-tooling and position fastening and size stability are imperative. From industrial CRTs to automation & robotics and specialty tooling, these parts find use.

This recap will take a look at the kinds of taper/and threaded dowel pins and applications, and how precision manufacturing processes like Swiss are making quality consistent for closer-tolerance engineering applications.

What is a Taper Dowel Pins?

Taper dowel pins are precision pins that are turned or similarly produced to give them a bit of a taper along their length, permitting them to achieve a snug, self-retaining fit when driven into a matching tapered hole. This pin geometry is commonly found in applications where positioning repeatable from an existing fit or avoiding shaking/vibration are necessary.

Applications for taper dowel pins include:

Precision fixture and tooling alignment

Machine element positioning

Mold and die assembly

Accurate replacement of members needed in mechanical systems

As a function of their use, taper pins must be made under strict diameter control with a good surface finish.

Threaded Dowel (and Threaded Tapered Dowels) Pins Explained

In some assemblies, the act of assembly itself may not be the entire story. Facility in joining and also easily removed and. positioned, may be as significant. Threaded dowel pins (and threaded tapered dowel pins) fulfill that task.

Threaded Dowels

“Common” (as opposed to specialty) threaded dowel pins have internal or external threads in their body to allow pins to be readily inserted, as well as easily pulled or screwed out with regular tooling. The “body” design of standard threaded pins is particularly appropriate in long-term situations, or extreme precision in assemblies in which members may periodically be disassembled.

Threaded Tapered Pin

Threaded tapered pins permit the equity of position of a tapered pin while allowing serviceability of a common threaded design. For areas of close approach or limited space, this feature is particularly desirable, as is the resultant addition of a screw hole in the side removed taper

For complex assemblies, members with internal threads are often preferred, as they avoid bodies of rippling threads projecting from the assembly.

Internally Threaded Dowel Pins

Internally threaded dowels are designed with a threaded hole at all or part of the length at one end of the body. This permits use of a screw or puller for accurate placement and/or removal, an invaluable feature in tight assemblies and other precise arrangements avoiding damage or alteration of the pin.

Most dowel pins are of durable material and common entries in this group are:

Stainless Steel

Alloy Steel

Carbon Steel

Tool Steel

Selection is according to load, corrosion resistance, and all aspects of the operating environment, while turning permits a ready extent of thread in each element of diameter and surface finish for quantity runs.

Common uses for tapered pins include:

Automation and robotics

Industrial machinery and equipment

Mold and die manufacture

Precision fixtures and jigs

Automotive and general mechanical assembly

In those apply the characteristic of a good die control and size, reliable thread, and true taper dimensions are all primary to enabling a yield such as that desired in those applications, and taper pins like the “common” of assembly are credibly used for many of those applications over, as are principal good suppliers/quality tapered pins’activites for standard and custom pins as is required above.

How Quality Dowel Pins are Achieved Through Precision Machining

Producing segmented dowel pins, both tapered and threaded, requires dedicated Swiss machining capabilities and quality execution. Swiss machining is widely used to produce these types of precision components, allowing manufacturers to create:

Strict tolerances on diameter and taper angle

Excellent concentricity from the body of the pin to the threaded features that mate to it

Clean appearance for good press or slip fit performance

Consistent repeatability for producing parts in volume.

Swiss machines excel for quality dowel pins of small diameter where the overall size of the pin itself becomes a factor in the accuracy of the assembly.

Custom Machined Pins and Shafts

Many uses for dowel pins don’t fit the general catalog pin sizes and characteristics found in many parts bins, such as:

Different taper angles and/or body shapes

Internal threads

Other lengths and diameters

Requirements imposed by particular manufacturing, material, or surface treatment

Manufacturers of properly designed custom pins and shafts can accommodate these requirements through flexible CNC and Swiss machining processes.

Learn more about precision machined pins and shafts designed for demanding mechanical and industrial applications.

Choosing Suppliers of Tapered Dowel Pins

Engineers and other buyers should consider when sourcing tapered dowel pins suppliers:

Machining Background – Extensive Swiss machining background assists in producing close tolerances on small pins

Materials – Flexibility in working with various steels and other alloys.

Tolerance Inspection – Proven process for testing parts with respect for particularing

Non-Standard Designs – Ability for producing other pins and shafts characterized for a particular application

Repeatability – Proven quality of production process for in quantities for handling parts.

Selecting a supplier who has experienced with pins and due to assembly related issues assists in eliminating problems and maintenance costs of the finished assembly.

Conclusion

Taper dowel pins, threaded dowel pins, and threaded tapered dowel pins are essential components for precision mechanical assemblies that require accurate alignment and secure positioning. From internal threaded designs to durable threaded metal dowel pins, quality manufacturing directly impacts performance and reliability.

By leveraging advanced Swiss machining services and precision CNC processes, manufacturers can produce high-quality dowel pins that meet strict engineering requirements. For applications requiring custom designs, partnering with an experienced precision machining supplier ensures consistent quality, accuracy, and long-term value.