Dowel pins and shafts are critical in ensuring that assemblies are properly aligned and load is transferred properly in medical devices, automation equipment, electronics, and industrial movers. Depending on the application, even the slightest of dimensional errors can throw off assembly or closing; or place unwanted stresses and premature wear on key components. In this post we will talk about different kinds of pins and shafts, how and where they are made, and why Swiss turning is so useful for high precision applications.

What are Dowel Pins and Shafts?

Dowel pins and shafts are cylindrical components used to locate or align assembled parts, or to transfer loads between them. While appearing simple, many of these pins and shafts involve exact tolerances, high quality surfaces, and need to be repeated with similar precision to avoid problems.

Common functions include:

Manufacturers of dowels Pins & shafts know that surface finish and size matter to ensure proper fit and long life.

Common Types of Dowels Pins & Shafts

Shoulder Dowel Pins

Shoulder dowel pins are a progressive step pin with a larger shoulder diameter and a smaller pilot diameter. The step means the part serves as both a locating feature, and a mechanical stop. Typical applications include:

Tooling and fixture clamping

Molding and die assemblies

Precise mechanical placement

Localization means that the step must also be concentric, leading manufacturers to utilize Swiss machining or CNC lathes.

Precision Ground Dowel Pins

Precision ground dowel pins are manufactured to critical tolerances, in the micron range and very often undergo secondary grinding themselves for high quality operation and use. Typical characteristics include:

Tight and consistent diameter tolerance

Straightness and roundness for proper fit

Smooth finish

Usability as a press-fit or slip-fit assembly

Precision Ground pins are key in components requiring accuracy, straightforward alignment.

Materials Used in Dowels Pins & Shafts Manufacturing

Depending on the specifics of the desired application, materials for dowel pins & shafts are often selected based on:

Stainless steel for resisting corrosion

Alloy steel for high strength and wear resistance

Tool steel enhancement

Brass or aluminum for weight purposes

While material affects performance, durability and manufacture, precision turning centers help ensure best properties are preserved through value-added machining.

Why Swiss Machining is Ideal for Dowel pins and Shafts

Swiss machining isn’t always necessary for every kind of dowel pin & shaft, but when parts are small and/or require tight tolerances, what better process than this? Key benefits include:

Quality dimensional control for long, thin components

Concentricity and straightness

Repeatability in production—lots of pin!

Lower vibration during machining

Pin bodies that are complex in geometry and form depend upon Swiss machining technology for achieving production consistency.

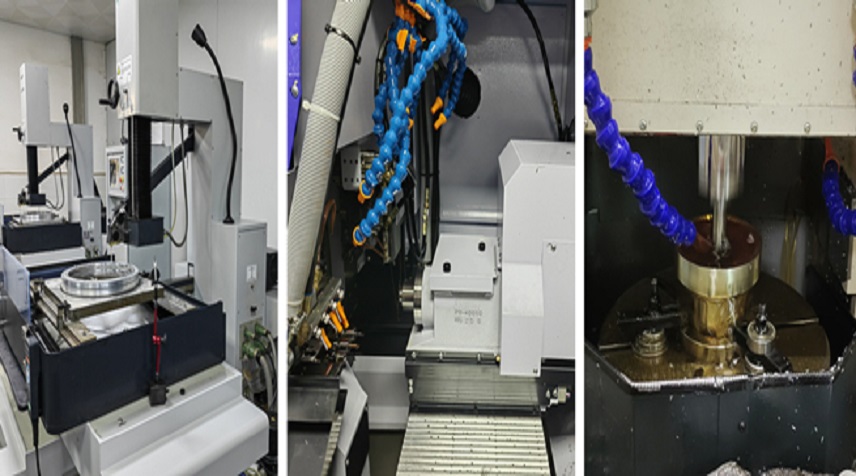

Common Precision Pins and Shafts Manufacturing Process

Production process for higher quality pins include several steps:

Material preparation—selection of certified materials

Swiss CNC Turning—Primary Forming with close tolerance control

Secondary Operations—Smoothing or cutting

For other types of custom pin and shaft applications, see pins and shafts custom manufacturing.

Applications for dowel pins and shafts

Dowel pins and shafts are used in a wide variety of industries, including:

Medical devices and surgical instruments

Automation and robotics systems

Industrial tooling and fixtures

Electronics and delicate equipment

In medical and other precision-engineered applications, a consistent level of tolerances and cleanliness of surface finishes is desirable.

About dowels pins & shafts inc. and custom manufacturing

Many people searching for dowels pins & shafts inc are instead looking for manufacturers of custom pins and shafts, rather than hardware ready to ship from stock. Custom manufacturing allows the engineer to specify as desired:

Fixed sizes and tolerances

Material and cleanliness of surface finish

Specific features, such as shoulders

Working with a custom-focused Swiss precision machining partner assures those parameters are met without risking quality or lead-time.

Choosing a manufacturer of dowel pins and shafts

When choosing a supplier of dowel pins and shafts consider:

Experience with precision pins and shafts

Swiss machining capabilities

Quality control and methods of verification

Material traceability and consistency

Your choice of supplier of shoulder dowel pins, and of precision ground dowel pins should be a trusted one, with experience in the most strict manufacturing processes.

Although physically small, dowel pins and shafts are major components of precision assemblies. From shoulder dowel pins to precision ground dowel pins requires a level of quality achievable through careful attention to machining, especially with a professional helping out through Swiss precision machining and dedicated pins and shafts manufacturing.