In the modern industrial world of fastener manufacturing, fasteners have become more essential than ever. Fasteners, like screws, bolts, and all of the pieces that fit together, are created with an emphasis on Precision and Dependability. Fasteners are crucial for ensuring Safety, Reliability, and Performance in a multitude of Applications. Therefore, companies should seek fastener manufacturers who have a proven track record of producing high-quality fasteners to meet their needs for quality and expertise in Engineering.

This article provides a discussion on the Precision Screw Manufacturing Industry and the benefits associated with partnering with an experienced Fastener Manufacturer. In addition, this article describes how modern Screw Manufacturers will leverage the latest in Swiss Machine Technologies to create high-quality precision screws.

What is a Fastener Manufacturer?

Fastener manufacturers are responsible for producing all fasteners, including screws, bolts, nuts, and other fastener components, according to precise dimensional specifications, material specifications, and surface finish specifications.

Typically, a Fastener Manufacturer will provide:

• A Custom Design Service for Fasteners.

• An Ability to Manufacture Large Quantities of Fasteners.

• A Consistent and Precise Manufacturing Environment.

• A Commitment to Adherence to Applicable Industry Standards.

Fasteners manufactured by Manufacturers are produced by utilizing reputable and reliable Suppliers to ensure that every Fastener is manufactured to the proper specifications for Performance and Safety.

Benefits of Precision Screw Manufacturing

Precision screw manufacturing focuses on creating fasteners that have extremely close tolerances, Dependable Thread Formations, and Outstanding Material Performance. Below are just a few Advantages of Precision Screw Manufacturing:

Increased Reliability of Components

Precision Screws will hold their Assemblies together Strongly under Conditions of High Stress, Vibration, or Temperature Variation.

Increased Flexibility of Materials

Precision Screw Manufacturers will produce screws from many Metals (such as Stainless Steel, Titanium, and Brass) as well as Engineering-Grade Plastics to provide Custom Solutions for Specific Applications.

Advanced Machining Techniques

With the advancements in Swiss Machining Technology, fastener manufacturers now have the ability to produce Miniature Screws and Components with Precision Tolerances and Repeatability.

Scalability

Fastener Manufacturers can produce Low Volume Prototype and Mass Production Runs, which allows for a Reliable Supply Chain.

The Role of Fastener Manufacturers in Modern Manufacturing

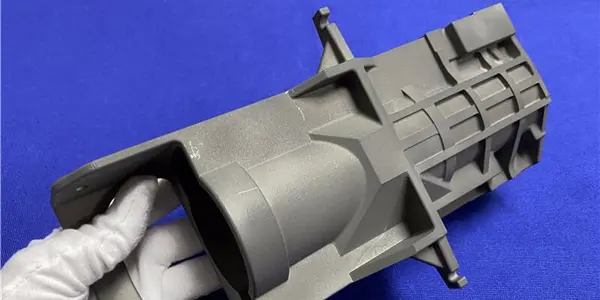

Fastener manufacturers have changed from simple assembly lines to Modern Manufacturing Facilities that have the Ability to Produce Highly Complex Parts and Maintain Qualified Tolerances. Modern Fastener Manufacturing Facilities typically have the following capabilities:

• CNC Turning and Milling for Precision Threaded Components.

• Multi-Axis Swiss Machining for Small and Complex Screws.

• Surface Finish and Plating for Anti-Corrosion Protection.

• Quality Assurance and Quality Control according to ISO Guidelines.

Selecting an established and reputable Fastener Manufacturer will provide you with Peace of Mind that your projects will be completed on schedule, to an acceptable level of quality, and with the Required Documentation for each project.

Choosing Your Bolts Manufacturer(s)

The following are the four primary considerations when choosing your bolts manufacturer(s):

1. Experience and Knowledge Base

An established manufacturer of industrial fasteners will most likely live up to your expectations for Quality.

2. Type of Products

When choosing Fastener Manufacturers verify that they manufacture many types of screws and bolts as well as Specialty Fasteners, such as Custom-Designed Fasteners.

3. Capability of Precision Manufacturing

When Selecting Fastener Manufacturers, confirm that they Utilize Advanced CNC and Swiss Machining Technology to assure Precision Tolerances and Surface Finishes on Products Produced.

4. Compliance and Certifications

Fasteners Manufactured by Manufacturers with ISO Certification are Traceable and Manufacture High Quality Fasteners.

For Companies looking for a full scope Solution to Product Development and Manufacturing, partnering with an expert Manufacturer of Precision Screws is an Excellent Method of Improving Efficiency in Product Development and Manufacturing Operations.

Types of Fasteners Produced

Professional fasteners factory companies produce a variety of fastening components, including:

Machine screws

Hex bolts and socket head screws

Nuts and washers

Specialty fasteners for medical, aerospace, or electronics uses

By using bolts and nuts manufacturing capabilities, businesses gain access to reliable, durable, and high-quality components for complex assembly.

Why Swiss Machining Ensures Fasteners Quality

Where small or intricate fasteners are required, Swiss machining is particularly useful. Swiss machines allow for:

High-precision thread cutting

Less wastage of raw materials

Tight tolerances on small diameters

Shorter production cycles, without loss of quality

More and more, modern screw factories and fasteners products manufacturers use Swiss machining for fasteners of metal and plastic types.

Check out our Swiss machining services and see how we turn out high quality screws, bolts and fasteners over and over again.

Conclusion

Whether you need to source simple screws, special bolts, or precision fasteners, you can’t go wrong working with an experienced fastener manufacturer. From precision screw factory to advanced Swiss machining, the modern screw factory is outfitted to meet the needs of the high-demand industries.

For quality bolts and nuts, and other fasteners solutions, working with professional fasteners factory partners is the best way to achieve superior performance and successful support for your projects. Find out about our precision Swiss machining services and bolts and nuts pages for the right fasteners for your business.