Falcon CNC Swiss is a specialist in precision machining for the semiconductor industry, manufacturing mission-critical components. We understand that microchip manufacturing requires a loyalty to accuracy, cafes, purity of material and cleanliness. Our precision CNC machining and Swiss machining services are for high-purity, high complexity parts that are utilized in wafer fabrication equipment, allowing for minimal particulate generation and maximum reliability in the most extreme environments including ultra-high vacuum (UHV) and plasma applications. Falcon will be one of your best choices for semiconductor component suppliers.

Critical Components for Semiconductor Fabrication

Semiconductor manufacturing equipment relies on precision machining with its mechanical components. There is no contamination/ contamination or failure. Our specialty is in precision CNC machining for critical applications such as:

Wafer Handling and Robotics

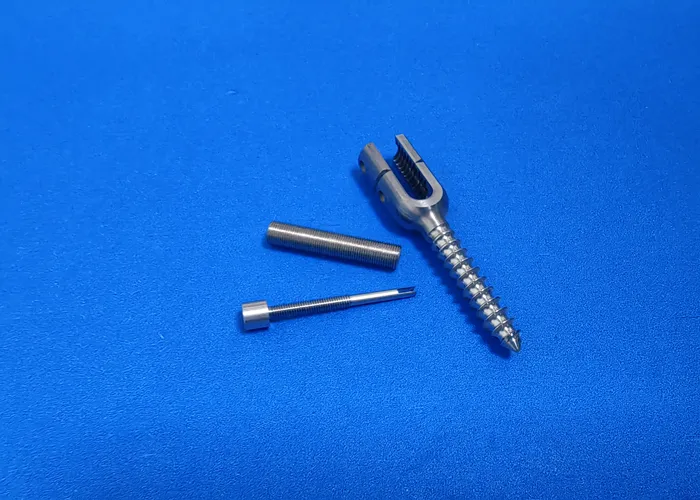

Wafer Handling Arms: The depicts robotic end effectors and blades that are extremely stiff and light to prevent particle shedding during relative wafer placement.

Elevator Pins: The precision-machined pins that execute the sensitive lift and placement of silicon wafers without exposing the surface to micro-scratching or contamination.

Chucks & Clamps: ESD-safe components and fixtures that secure wafers during lithography, etch and inspection.

Vacuum & Process Chambers

We precision machine critical semiconductor vacuum chamber components such as:

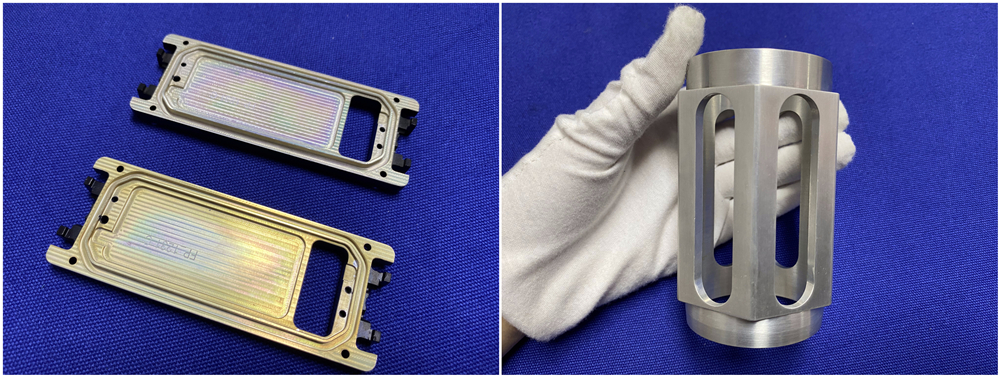

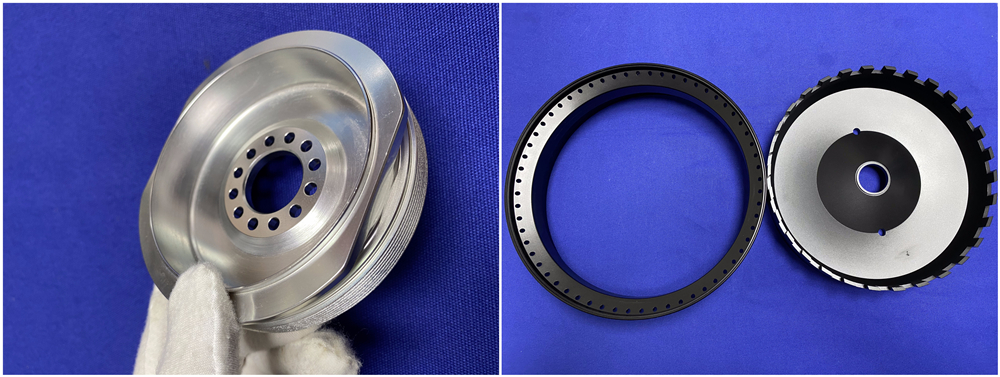

Faceplates and Diffusers: Complex and plasma resistant parts with precision gas flow channels and cooling systems for etching and CVD chambers.

Chamber Liners and Shields: Non-contaminating parts that protect the walls of chambers while still being relatively easy to replace to minimize tool down time.

Feedthroughs and Flanges: Ultra-high vacuum (UHV) aluminum vacuum chamber machining parts that maintain their integrity throughout high temperature cycles and high vacuum without losing performance.

Fluid & Gas Delivery Systems

Manifold Blocks: Complex and flowing gas delivery manifold blocks, to ensure that critical chemical delivery is conducted as intended with machined, internal passages.

Nozzles & Fittings: Chemical resistant parts for high-purity gas and high-purity liquid delivery systems that also require corrosion resistance and leak-free performance.

Our Semiconductor-Specific Capabilities

Manufacturing for semicon instead of precision machining means that semicon manufacturing requires a specialized method for every step.

Materials for demanding environments

We expertly machine materials that adhere to the stringent requirements of this industry:

Aluminium 6061-T6: Anodized to ensure corrosion resistance and particle containment.

Stainless Steel 316L: For corrosion resistance and low carbon content, stainless steel parts are often electropolished.

Engineering Plastics (PEEK, Vespel, PPS): For electrical insulation while maintaining low friction and avoiding chemical.

Exotic Alloys (Inconel, Hastelloy): For extreme temperature high performance corrosion resistance.

Specialized finishing for cleanliness

Hardcoat Anodizing (Type III): To provide a hard and non-shedding resistance to plasma erosion.

Electropolishing: Eliminates microscopic material from the surface, removes particulates and produces a passive oxide layer that creates excellent qualities for stainless steel components.

Ultra-Sonic Cleaning: We are able to effectively clean and package components in cleanroom-compatible materials, so components arrive ready to be installed!

Rigorous Quality Assurance

We have a rigid set of quality protocols, including:

Cleanroom Assembly & Packaging: For total cleanliness and to prevent contamination.

First Article Inspection (FAI): Achieves total dimensional validation with dimensional check of shop floor output will to customer drawings.

Material Certification: Total traceability with all raw materials.

Why Work with Falcon CNC Swiss?

Industry Knowledge

We understand the language of semiconductor manufacturing. We know how important it is to mitigate risks of outgassing, particulate creation, and plasma-induced damage, and we build it into our processes.

Custom semiconductor parts machining from prototypes to high-volume production

We start supporting OEMs with prototypes through High-Volume Production, maintaining design integrity through the ramp-up in production.

Technical Engagement

Our Engineers will give DFM (Design for Manufacturability) input, providing more opportunities for performance, cost, and manufacturability improvements, all within the requirements of enclose semiconductor applications.

Your equipment enables the next generation of technology. We could enable your equipment with precision components that meet and exceed the Semiconductor industry’s extreme requirement.

Request Your Confidential Quote for Semiconductor Parts Today!

Frequently Asked Questions (FAQ)

What tolerances can you hold for semiconductor components?

We routinely machine parts to tolerances of ±0.0002" (0.005mm) or tighter for critical features to make sure a perfect fit and function within complex assemblies.

How do you guarantee that parts are clean and will not generate contamination?

All our processes are clean - we utilize dedicated tooling for certain materials, have strict handling procedures, ultrasonic clean and package in ISO8 cleanroom meeting IEST standards.

Can you machine parts that resist plasma erosion?

Yes, we regularly machine parts that resist plasma erosion. For example, we machine plasma resistant from anodized aluminum, and special coatings made for aggressive Plasma Exposures for parts located in etch and deposition chambers.

Do you provide material certifications and full traceability?

Yes, we provide material certifications and full traceability for all raw materials used in your Semiconductor component. This is a critical requirement for most OEMs.