Falcon CNC Swiss is a leading manufacturer of critical components for the next generation of robotics and industrial automation. We manufacture high-precision, lightweight, and highly reliable components for robotic arms, collaborative robots (cobots), and automated systems so they can operate at high speed, accuracy, and repeatability. From prototype to production, we provide the manufacturing partnership that innovative automation companies depend on.

Enabling Innovation in Robotic Systems

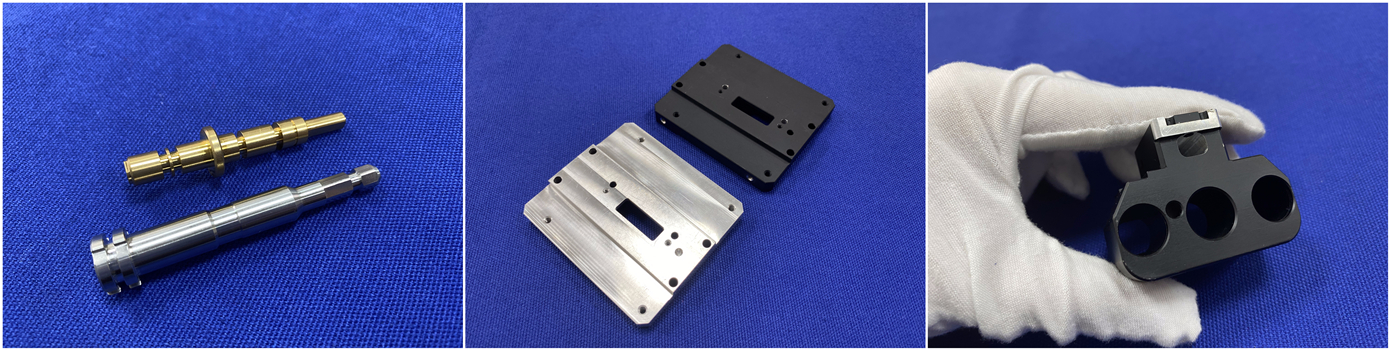

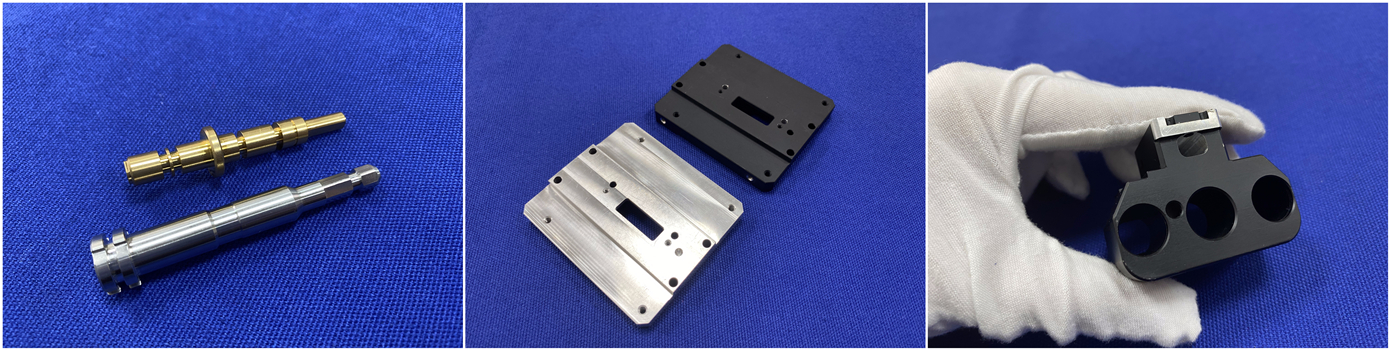

As experienced robotic parts manufacturers, we understand that system performance is defined by the precision of its industrial robot components. Every joint, actuator, bracket, etc. needs to be machined to very close tolerances to eliminate vibration, backlash, and weight while maximizing stiffness and durability. Our capability in precision multi-axis machining and Swiss machining services is well suited for the complex geometries and tight tolerances this industry requires.

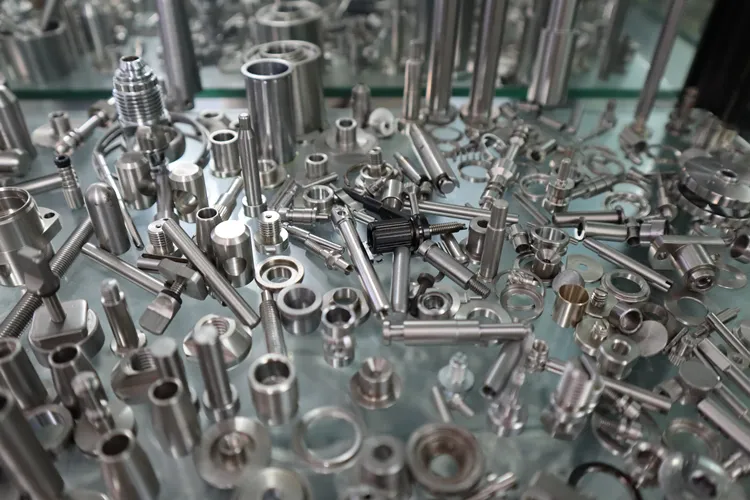

Key Robotic Components We Machine:

Robotic Arm Structures: Aluminum robotic arm links and housing units, as well as joint components that require the greatest stiffness-to-weight ratio.

Actuator & Drive Components: Parts for harmonic drives, planetary gear boxes, and linear actuators that require ultra-high precision and repeatability.

End-Effectors (Grippers): Custom end effector machining for gripper jaws, tool changers, and specialized manipulation tools.

Sensor Mounting Brackets: All mounting for vision systems, LiDAR, and force/torque sensors where absolute stability and precise alignment matter.

Our Advanced Machining Capabilities for Robotics

Whether you need simple brackets or complex assembly, our advanced machine shop can handle any robotics manufacturing for you from start to finish. We strive to make it easy for you to take your product from concept to a high volume production.

| Capability | Description | Benefit for Your Robotics Project |

| Rapid Prototyping | Accelerated turnaround for design validation and functional testing. | Get working parts in hand faster, reduce development cycles, and iterate designs quickly. |

| High-Volume Production | Scalable, automated production runs with rigorous process control. | Meet market demand with consistent, high-quality parts delivered on time, every time. |

| 5-Axis CNC Machining | Complex contouring and ability to machine multiple sides of a part in a single setup. | Produce intricate geometries (e.g., robotic arm links, sensor housings) with unmatched accuracy and efficiency. |

| CNC Swiss Turn-Mill | Simultaneous turning and milling for complex, miniature parts with extreme precision. | Ideal for small, high-tolerance components like actuator parts, connectors, and pins within robotic joints. |

Multi-Axis Mill-Turn | Complete machining of complex parts from bar stock or blanks in one operation. | Reduce part handling, minimize overall production time, and ensure superior part concentricity. |

| Complex Assembly | In-house kitting and light assembly services for multi-part components. | Simplify your supply chain and receive ready-to-install sub-assemblies, reducing final assembly time and cost. |

This complete suite of capabilities ensures that regardless of the complexity and volume of your robotics components, we have the technology, processes and experience to manufacture them to the highest standard of precision and reliability.

Precision Parts for Industrial Automation

Apart from robots, modern manufacturing also uses a wide range of automated equipment in an ecosystem. We manufacture the components that ensure these systems run properly 24/7.

Key Automation Components:

Linear Motion Systems: Components that are part of linear guides, gantry systems, and ball screw actuators.

Custom Automation Fixtures: Precision machining for jigs or fixtures that hold parts for assembly, inspection, or processing.

Feeding & Sorting Mechanisms: Parts for vibratory bowls, conveyor systems, and sorting gates.

Connection Interfaces: Precision machined connectors and mounting plates for modular automation.

Why Falcon CNC Swiss is Your Automation Partner

Mastery of Lightweighting

We help you win the battle of mass. By machining features and using chosen materials such as aerospace-grade aluminum and titanium, we allow you to machine components that reduce inertia, increase velocity, and reduce power consumption while not reducing strength or rigidity.

Uncompromising Precision

Repeatability is everything in automation. We hold a tolerance of ±0.0005" (0.0127mm) regularly, which ensures perfect fit and function batch after batch. This eliminates assembly errors and guarantees your systems operate as intended.

From Prototype to High-Volume Production

We reduce your innovation cycle times. Our rapid prototype service gives you the ability to iterate and test designs quickly.

Once you finalize the design, we transition to high volume production or high volume Swiss CNC production seamlessly through consistent and certified quality processes that will satisfy your production demands.

Full-Service Engineering Support

We are the manufacturing partner for your company. Our engineering team provides valuable Design for Manufacturability (DFM) feedback and helps you make design changes that simplify manufacturing, reduce costs, and improve performance of your robotics and automation components.

Contact us to discuss your project and experience the difference a dedicated custom robotic parts manufacturer can make.

Materials We're Good At for Robotics

Aluminum 6061-T6 & 7075-T6: The premier aluminum for its great strength-to-weight ratio as well as ability to be machined.

Stainless Steel (304 & 316): For those components requiring corrosion resistance and extra durability.

Titanium (Grade 5): For high-end applications that require maximum strength and minimum weight.

Engineering Plastics (PEEK, Delrin): For the use in specific component applications requiring electrical insulation, low friction, and chemical resistance.

Power your innovation with precision you can trust. Let's build the future of automation together.

Request Your Free Quote for Robotics Component Today !

Frequently Answered Questions (FAQ)

What qualifies a part for robotics and not general CNC machining?

Robotics parts are special in three main areas, (1) Lightweighting (to get the inertia down), (2) High Stiffness (to keep deflection and vibration to a minimum), and (3) Extreme Precision (to ensure repeatability and accuracy). Our procedures are designed to accomplish these goals.

Can you machine complex internal passages for air or hydraulic lines in robotic arms?

Yes. Our multi-axis machining centers are capable of machining complex internal channels and lightening pockets within the links of robotic arms to simplify assembly and keep system weight to a minimum.

Do you offer anodizing or any other surface finishes?

Yes. We offer hard coat anodizing for wear resistance, black oxide, and other finishes to protect the part while meeting the aesthetic or functional properties.

We are a startup and have a new robot design. Can you help with lower volume prototype runs?

Yes. We partner with start-ups, and R&D departments very actively to prototype new designs for robotics. Many times we can provide recommendations that apply a lot of cost-effective ways to simulate parts that will eventually be cast or forged and use a machined billet.