Introduction: The Rise of Screw Machine Products in an Insatiable World

At Falcon CNC Swiss, we’ve seen the signs of the times all too clearly: day in and day out, there’s no respite from the tide of demand that engulf us. Hushed whispers of great engineering feats long inscribed in history evaporate when faced with the reality of milled metals. Designers and engineers, so often our allies, seek a screw machine products company they can rely on to bring their innovations from the mind’s eye into great longevity on the market. The time has come for their dream come true, integrated through the elegant engineering of automatic screw machine products.

This guide leads you through defining screw machine products, the benefits and challenges of screw machine part production, and the criteria for choosing a screw machine products manufacturer. What are screw machine products? We start from the beginning.

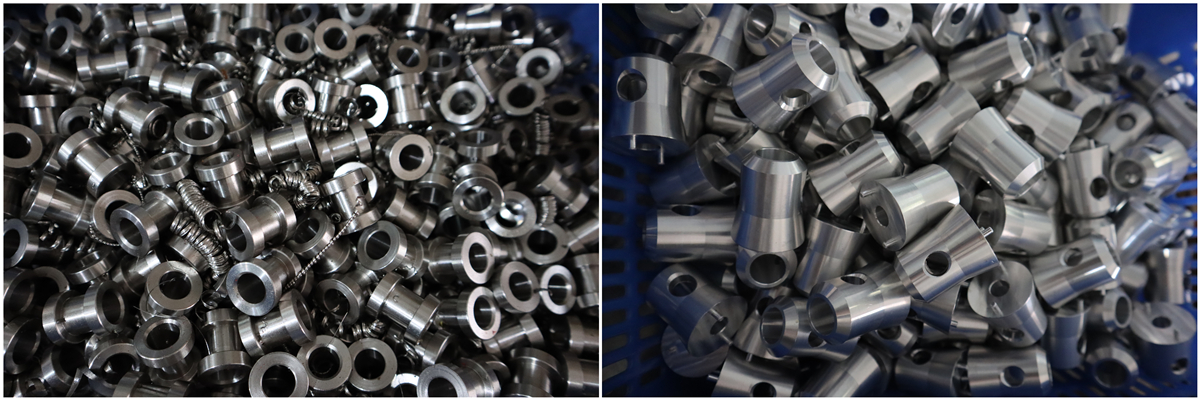

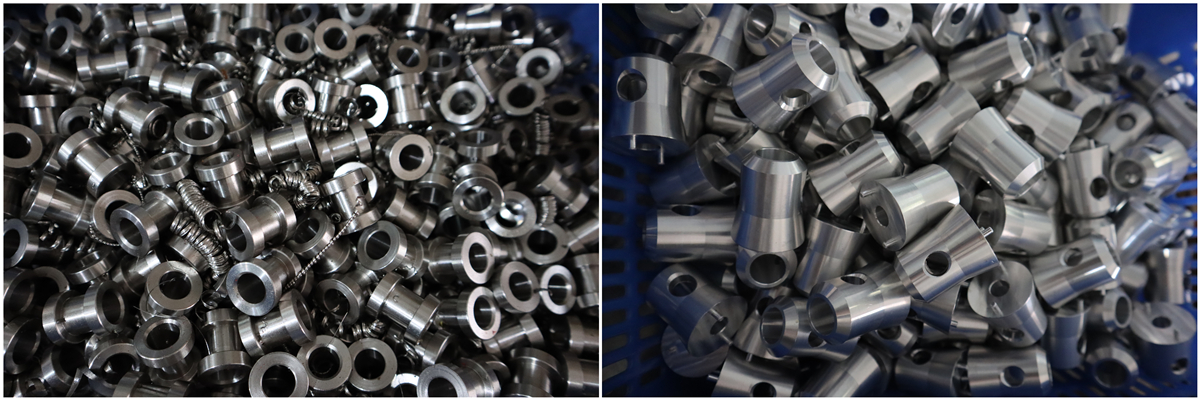

Exactly what are automatic screw machine products?

Automatic screw machines are programmable lathes for the mass production of small metal parts, typically screws, but now multi-featured precision machined parts. Recent versions, particularly CNC Swiss-type lathes, have greatly amplified the scope of these lathes. “Automatic,” means these lathes will perform several operations (turning, drilling, milling, etc., threading) in one set-up with very little human attention. The result is automatic screw machine products with:

Tight tolerances across thousands of pieces

Complex shapes in one chucking

Excellent finishes

Cheap per piece price at medium to high volumes

Examples of automatic screw machine products are precision pins, shafts, couplings, bushings, valves, and fasteners used in medical devices, aerospace, automotive, and electronics.

Engineering Advantages: Why Automatic Screw Machining

1. Unmatched Accuracy and Repeatability

Because the guided bushing supports the workpiece so closely to the cutting action, practically all tool pressure deflection is negated.Offshore parts often have tolerances of ±0.0005" (0.0127mm) maintained from part to part over long runs needed by medical, aerospace, and other industries requiring close tolerances.

2. Efficiency and Lower Labor Costs

After being programmed and set up, an automatic screw machine will run unattended for hours and is capable of producing finished parts with second operations. This situation is a big time and cost saver on a per unit basis than a conventional lathe requiring several setups.

3. Range of Materials and Waste Reduction

From brass and aluminum to stainless steels and other exotic materials, modern day automatics work with a wide range of materials. Virtually every automatic screw machine products company redirects scrap from used stock, and bar stock with optimum tool path utilization minimizes waste of materials and is a key factor in its cost and conservation.

4. Complex Parts All in One Operation

With the availability of live (rotating) tools, and/or secondary spindles, parts can leave the complete shop with front and back finished, all in one operation. This done-in-one work method lowers the chances for errors in handling, improves quality control, and shortens delivery times.

A Checklist for Engineers Choosing a Screw Machine Products Manufacturer

Finding a partner from among the many screw machine products manufacturers isn’t simply a matter of asking for a quote. Here are factors to consider.

Technical and Engineering Support

Does the manufacturer provide Design for Manufacturability (DFM) feedback? Do their engineers offer design tweaks that may improve reliability, build quality, or reduce costs without eroding performance? The collaborative engineering phase is essential to most Falcon CNC Swiss projects.

Equipment and Technology

A modern automatic screw machine products company inc will have multi-axis CNC Swiss lathes with live tooling, Y-axis capabilities, and in-process measurement and inspection systems. Ask about machine age, control systems, and how they ensure consistent geometric accuracy.

Quality

An ISO 9001 certification is a health check, but for some industries you’ll want evidence of a solid Quality Management System (QMS) and other specific quality control protocols and documentation, including full material traceability back to a certified automatic screw machine products co.

Common Materials for High-Performance Automatic Screw Machine Products

Material selection directly impacts performance, cost, and manufacturability. Here’s a brief engineering overview:

| Material | Typical Applications | Key Advantages for Automatic Machining |

| Brass Alloys (C360) | Electrical connectors, plumbing fittings, decorative hardware | Excellent machinability, high speed production, natural corrosion resistance, good conductivity. |

| Aluminum (6061, 7075) | Aerospace brackets, electronic housings, lightweight actuators | High strength-to-weight ratio, good machinability, anodizable for surface hardening. |

| Stainless Steel (303, 316, 17-4 PH) | Surgical instruments, food processing parts, marine hardware | Superior strength and corrosion resistance. 303 offers best machinability. |

| Precision Alloy Steels | High-strength pins, shafts, and automotive components | Can be heat-treated for exceptional wear resistance and durability. |

A proficient screw machine products company will guide you through this selection based on your part's functional requirements, environmental exposure, and budget.

Why Work with Falcon CNC Swiss for Your Automatic Screw Machine Products?

While we put our decades of machining experience at your service, cutting metal parts is really only part of our approach. Falcon CNC Swiss wants to be part of every project, starting with your CAD model to ensure that manufacturability, maintainability and performance are all considered.

Our technology suites feature several modern multi-axis CNC Swiss automatics that are capable of producing the most intricate automatic screw machine products. We both design and run our machines for you.

Important is our vertical integration. Falcon CNC Swiss maintains control of the entire process under one roof, from material to finishing and testing. Things get done, and when you specify your timeline, we meet it.

What’s more, you are no longer a customer, you’re a partner. A vital part of our business is what follows just-in-time delivery: it’s a commitment to you that the small components we produce for you are performing their intended duty, day after day. We’re part of your communications network, just-in-time.

Need parts for a life-saving medical device? Critical aerospace assembly? Our Swiss machining capabilities are built on a foundation of technical excellence and high standards of quality.