Falcon CNC Swiss is a leading optical component manufacturer and supplier of critical precision components for optics and photonics applications.. Building the complex mechanical parts behind advanced laser systems, imaging systems, spectroscopic devices, fiber optic communication, and more, requires precision and reliability. We are not making the lenses but the structures and mounting components with the precision and thermal stability demanded in the field.

Falcon CNC Swiss offers services that focus on optical precision machining. We offer high-quality optical precision machining solutions for the manufacture of often complex and delicate optical components. Optical precision machining is carried out using a variety of advanced CNC optical machining technologies to deliver the stringent accuracy and surface finish standards required by the optical industry.

The Photonics Revolution: More Than Just Optical Elements

While we have historically focused on optics lenses, photonics means the generation, detection, and manipulation of light itself, which involves incredibly precise mechanical parts that house, align, protect, mechanically adhere, and hold sensitive optical elements. Our CNC optical machining services are essential in machining those non-optical parts that are fundamental to your system's performance.

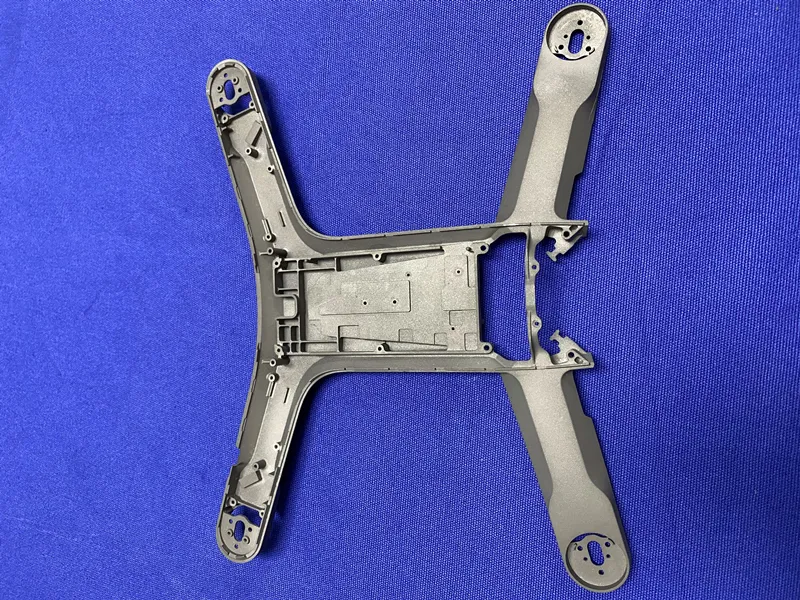

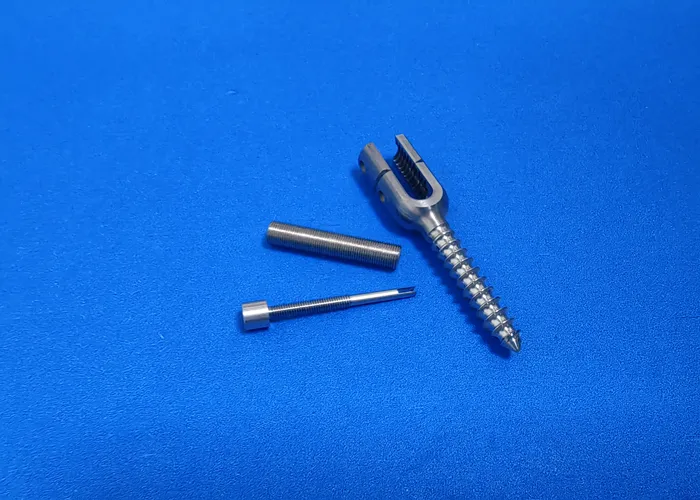

Examples of Major Components We CNC Machine for Photonics Systems:

Laser Systems - Laser diode housings, laser diode heat sinks, heat sinks and electrode isolators, resonator mounting plates. All of these components depend on exceptional thermal management.

Fiber optics assembly parts - fiber optic connector ferrules, fiber optic connector adapters, fiber optic V-blocks, fiber optic splice housings are just a few ways we help achieve precise light transmission.

Precision Mounting Hardware - kinematic mounts, mirror mounts, lens holders, optical posts, etc. All include complex adjustment features based on client designs.

Sensor & Detector Housing - This could involve enclosures for CCD/CMO sensors, photodiodes, and LiDAR sensor housing that require shielded accommodation to protect electronic sensors from light interference.

UHV (Ultra-High Vacuum) - chambers, flanges, and mounts for scientific and semiconductor equipment with specifications on outgassing and the purity of components.

Our Capabilities as a Precision Optical Components Manufacturer

Falcon is your professional precision optical components manufacturer partner, we support the optics industry at large producing critical tolerance, machining fixturing and mounting platforms for optical systems to ensure they remain aligned and functional.

Dimensional and Thermal Stability

Optical systems will have critical alignment to the precision of a scientist measuring laser energy in microns. Positioning systems and materials must address the real world effects of movement, thermal expansion, and effective long-term dimensional stability. We have on staff experts to machine the structural components to be dimensionally stable in the long term.

Complex Geometries and Tight Tolerances

Microns are common for dimensional tolerances we routinely machine. Parts may have complex geometries, sharp corners, and ultra-tight tolerances that are directly related to the integrity of optical paths and alignment.

Special Finishes

Anodizing - can provide corrosion protection, electrical isolation, or consistent durable surface.

Blackening - is applied to surfaces to reduce a surface's optical characteristics such that stray light does not reflect within an optical assembly.

Polishing - Highly polished surfaces required to ensure surfaces meet in vacuum or cleanroom workspaces.

And much more.

Why Falcon CNC Swiss for optics and photonics work?

Partner with a trusted optical component supplier that bridges innovation with mechanical precision.

Expertise in Critical Materials

We are CNC machining experts in critical materials for photonics such as:

Aluminum--- (while sufficient in light material and thermal characteristics)

Stainless Steel--- (highly durable multiple applications in structure)

Copper--- (best heat dissipation for laser systems)

Engineering Plastics, including PEEK and Vespel--- ( electrical insulating and low friction)

Unwavering Quality Assurance

We understand that an out of spec component on a critical optical system breaks the entire system, and our quality assurance includes quality control to ensure our clients expectations are achieved. Our quality assurance process includes CMM inspection, who after they optimize their configuration, inspect to ensure all parts satisfy your specifications of fit, form, and function.

Prototyping to Production

Whether requiring a prototype for an R&D project, or commercial production, our business possesses flexible manufacturing capabilities, suitable to install new programs to meet your needs and can ramp production as required. Also our hundreds of CNC machines are able to provide Swiss CNC machining service and high volume production CNC machining for optics & photonics products.

Your innovation in light needs a foundation of mechanical precision. Let Falcon CNC Swiss manufacture the important components that drive your optics and photonics breakthroughs.

Request Your Free Photonics Quote Today !

Frequently Asked Questions (FAQ)

Do you machine the actual lenses or optical glass?

No, we only machine the mechanical components and housings designed to hold and align optical elements. Our machine shop is outfitted to machine the metals and plastics necessary to build the body of your photonic device.

What tolerances can you hold for optical mounting components?

We routinely hold tolerances of ±0.0005" (0.0127mm) or closer to that for critical features. We will discuss your application with you to ensure that we deliver the precision you need.

Can you put black oxide or blackening finishes on the parts to minimize light scatter?

Yes. We offer several blackening finishes, consisting of anodizing and specialized coatings to minimize stray light reflection on internal surfaces of elements involved in optical assembly.

My assembly needs to be assembled in a cleanroom. Do you have that capability?

Yes, we can accommodate the assembly and packaging protocols required for cleanroom, providing your components clean/contaminant-free which is a critical requirement for sensitive optical & photonics applications.