Aluminum CNC Machining Capabilities

As a specialized aluminum CNC machining manufacturer, Falcon CNC Swiss provides,Falcon CNC Swiss provides advanced aluminum machining using state-of-the-art CNC mills, lathes and Swiss type lathes for custom aluminum parts. We machine aluminum grades such as 6061, 7075 and 2024, providing excellent strength and machinability.

| Capability | Details |

| Tolerances | ±0.005 mm |

| Materials Supported | 6061, 7075, 2024, 5052, etc. |

| Max Part Size | Ø300 mm / up to 600 mm length |

| Surface Finish | Anodizing, bead blast, polishing |

| Equipment | 5-axis CNC, Swiss turning, EDM |

Visit our section about precision Swiss machining capabilities for high-precision, small aluminum parts!

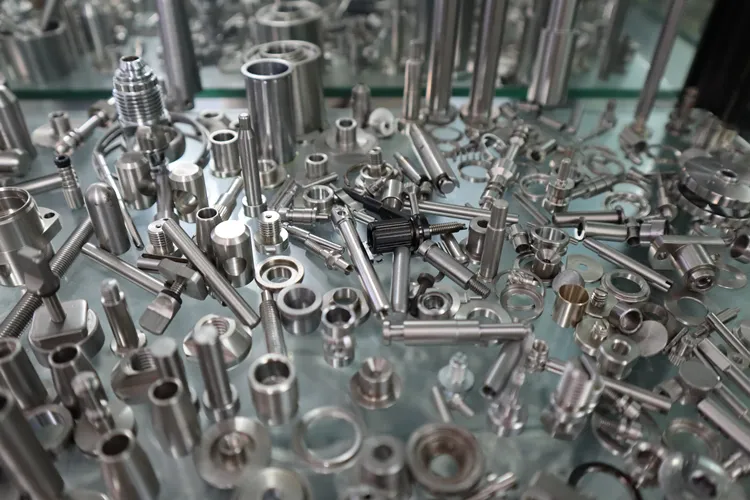

Custom Aluminum Parts Manufacturing Solutions

We are your expert partner for custom aluminum machining and manufacturing solutions, Falcon CNC specializes in custom aluminum parts manufacturing for many industries, including aerospace, medical, electronics, and automotive. Our engineers can help with DFM (Design for Manufacturability) to provide the best value without sacrificing structural integrity.

Typical components produced include:

CNC aluminum housings and enclosures

Heat sinks and thermal transfer components

Aluminum spacers and bushings in high volume

Sensor brackets, gears, casings

Visit our Custom Machining Services section for complex aluminum part solutions.

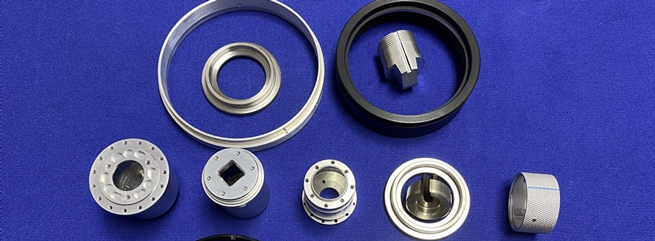

Precision Turned And Milled Aluminum Components

We provide precision aluminum turning and milling with Swiss CNC lathes and multi-axis machining centers, while consistently producing parts within tolerances. Our turning centers are great for long run parts, while our 5-axis machines allow for more complexity of design.

Key features:

Fine tolerances for RF shielding components

Smooth anodizing-ready finishes

Full traceability for aerospace and medical requirements

Batch production or one-off prototyping

Visit our Precision CNC Machining Service page to discover our quality standards!

Aluminum Component Supplier And Manufacturing Network

Falcon CNC Swiss is a premier aluminum machining parts manufacturer and reliable CNC machined aluminum parts supplier that provides a dependable supply of high quality components at affordable prices to customers at home and abroad in North America and Europe, or any other area globally.

Supplier Achievements:

ISO 9001, 16949, 13485 Certified

Aluminum parts exported to USA, Germany, UK

Flexible MOQ & quick turnaround

Fluent communication & full documentation

Collaborate and form a partnership with our Swiss Machine Shop for your source of CNC Aluminum components long term.

Why Choose Falcon CNC for Custom Aluminum Machining?

15+ years of aluminum CNC machining experience

In-house Swiss-type turning & 5-axis milling

Precision for complex designs and tight tolerances

Affordable aluminum components manufacturing in China

Complete documentation and customer support

Contact us for free quote on all your custom machined aluminum parts today!

FAQ – Aluminum Precision Machining

Q1: What is aluminum precision machining?

Aluminum precision machining refers to the use of advanced CNC machines to produce aluminum parts with tight tolerances, high dimensional accuracy, and consistent quality. The process includes CNC milling, turning, drilling, and tapping to create complex aluminum components according to engineering drawings.

Q2: What industries use aluminum precision machined parts?

Aluminum precision machined parts are widely used in electronics, automotive, aerospace, medical devices, industrial equipment, and robotics. Aluminum offers an excellent strength-to-weight ratio, corrosion resistance, and superior machinability, making it ideal for precision applications.

Q3: Which aluminum grades are suitable for precision machining?

Common aluminum grades for CNC precision machining include 6061, 6061-T6, 7075, 2024, and 5052. Aluminum 6061 is the most commonly used due to its balance of strength, machinability, and cost, while 7075 is preferred for high-strength structural components.

Q4: What tolerances can you achieve in aluminum CNC machining?

Typical tolerances for aluminum CNC machining range from ±0.005 mm to ±0.02 mm, depending on part geometry and design requirements. Tighter tolerances can be achieved for critical features with proper design evaluation and process control.

Q5: What CNC processes are used for aluminum precision machining?

We use CNC milling, CNC turning, drilling, tapping, and multi-axis machining to manufacture aluminum precision parts. These processes can be combined to produce complex geometries and high-accuracy aluminum CNC machining parts.

Q6: Is aluminum CNC machining suitable for both prototyping and mass production?

Yes. Aluminum precision machining is ideal for rapid prototyping, low-volume production, and high-volume manufacturing. CNC machining ensures repeatability and consistent quality across different production scales.

Q7: Do you provide OEM aluminum precision machining services?

Yes. We provide full OEM aluminum precision machining services, supporting custom designs, drawings, and technical requirements. From engineering review to final inspection, each aluminum CNC part is manufactured to meet customer specifications.