Search

What are you looking for?

Falcon CNC's Swiss machining services provide unrivaled precision for valves and couplings in critical industries. Swiss machining guarantees superior accuracy, exceptional surface finish, and close tolerances — all of which are excellent attributes for precision components such as fluid control valves and fluid couplings.

As a manufacturer based in China, Falcon CNC combines the economic benefits of production with state-of-the-art CNC Swiss lathes, making us an expert and supplier of choice for companies worldwide looking for high accuracy valves and coupling components. We also serve customers that require Swiss turned components for a range of demanding industries including medical devices, automotive systems, and industrial machinery with reliability and quality performance.

As a result, our customers can enjoy local knowledge and expertise about machining and machining for your valves and couplings, while relying on global approach to quality and precision. Using Falcon CNC allows you to improve your product and process challenges with Swiss machined valves and couplings.

At Falcon CNC, we specialize in Swiss machining valves and couplings in China for demanding automotive and medical applications. We also offer material customization for the valves, such as Ti-6Al-4V valves (ASTM F136) for implantable ports, and 316L stainless steel couplings for sterile fluid systems.

For the automotive sector, we Swiss machine Inconel 625 couplings for electric vehicle battery cooling, and PEEK couplings with Vespel® seals for hydrogen fuel cell applications. All parts are precision Swiss-machined, precision-tested, and ISO-certified to meet or exceed qualification standards to ensure no risk to our customers and proper performance for clients around the globe.

Whether you need a high-performance valve or precise fluid connectors, Swiss machining valves or couplings, or both, Falcon CNC specializes in custom-engineered solutions in China.

| Material | Applications | Key Properties |

| Ti-6Al-4V | Implantable drug delivery valves | Biocompatible, MRI-safe |

| Inconel 625 | High-temperature fuel lines (EV batteries) | Resists oxidation up to 980°C |

| PEEK | Semiconductor chemical delivery systems | Electrically insulating, chemical inert |

Falcon CNC is an ISO-certified Swiss machining company in China that specializes in the manufacture of valves and couplings for end-users and manufacturers around the world. We adhere to a consistent commitment to quality assurance to ensure that each part is manufactured in accordance with rigorous international standards. Whether it is an OEM client requiring high-tolerance valves, couplings, or Swiss-turned parts, we have robust inspection systems to assure quality and quality assurance certifications in place to give our customers peace of mind. As a supplier of precision Swiss machining services in China, we serve the OEM marketplace including medical device manufacturing, fluid control, and general industrial systems with precision Swiss machining along with a focus on consistency and cost.

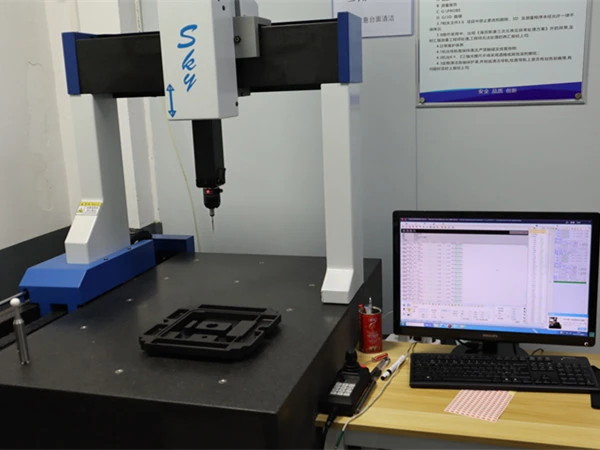

All components undergo 100% CMM inspection with detailed reports, including:

Dimensional Accuracy: ±0.001mm tolerance verification.

Pressure Testing: Hydrostatic testing to 10,000 PSI for hydraulic valves.

Certifications: ISO 13485, FDA 21 CFR Part 820, RoHS

Optimize your hydraulic, pneumatic, or fuel systems with Swiss-machined valves and couplings.

✅ Pressure-Tested to 10,000 PSI

✅ AS5202 & SAE J1926 Compliance

Download Now →

"Falcon delivered 50,000 Inconel 625 fuel line couplings for our hydrogen-powered vehicles. Their cryogenic machining prevented embrittlement at -40°C, and the ITAR-compliant documentation accelerated DOD approvals."

– James Park, Senior Engineer

✓ ITAR-Registered Project

FAQ

Q1: What tolerances are achievable for valve spools?

A: We hold ±0.001mm on spool diameters and 0.005mm cylindricity for smooth operation in hydraulic systems.

Q2: Can you machine anti-vibration couplings?

A: Yes. Delrin® AF couplings with Swiss-machined dovetail grooves reduce NVH by 30% in industrial pumps.

Q3: How do you test valve leak rates?

A: We use helium mass spectrometry and ISO 5208 protocols to certify leak rates <0.1 sccm.