Search

What are you looking for?

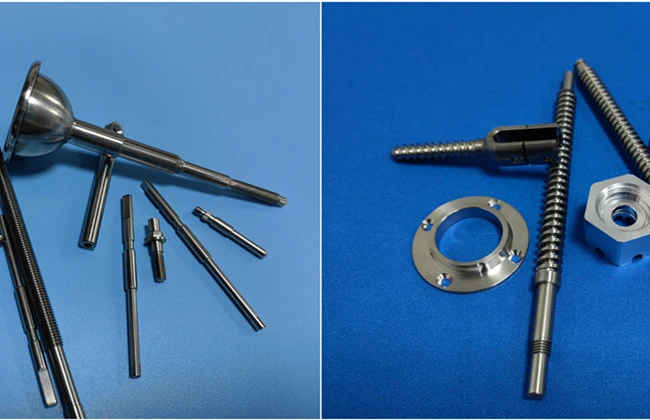

Falcon CNC is a reliable Swiss machining manufacturer located in China. We utilize CNC Swiss turning technology to produce precision pins and shafts for a wide variety of applications. Our moving headstock machines promote no deflection during the machining process to produce a very high level of accuracy and repeatability.

We are able to provide shafts with a mirror-polished finish in some applications, which can be useful for hydraulic systems that require reduced friction. Materials include 316L stainless steel, Ti-6Al-4V alloy, and Inconel 718 meeting ASTM standards and designed for durability and thermal stability.

Falcon CNC is reliable to provide a consistently high level of quality, speed of delivery, and price competitiveness for applications worldwide. Please contact us today if you would like to learn more about our custom Swiss-machined pins and shafts, or our capabilities, or request a quote.

At Falcon CNC, we focus on Swiss machining services for precision pins and shafts. Our services comes with custom designs and advanced surface treatments, with high quality materials for strength and durability. Industries we serve include automotive, electronics, and medical devices. Our CNC Swiss machining produces unsurpassed results. As a company located in China, we provide fast and low cost solutions for your precision components.

| Material | Applications | Key Properties |

| Ti-6Al-4V | Surgical robots, spinal implants | Biocompatible, 40% lighter than steel |

| 17-4PH Stainless | Automotive drivetrains, industrial valves | Hardenable to HRC 45, corrosion-resistant |

| Inconel 718 | Aerospace actuators, oil & gas tooling | High-temperature resistance (up to 700°C) |

Falcon CNC specializes in Swiss machining for the medical, automotive, and electronics industries. We manufacture implantable pins for joint replacements, surgical shafts for robotic actuators, and automotive shafts for EV drivetrains. All parts receive 100% inspection via CMM to ensure dimensional accuracy of ±0.001mm and surface integrity.

Falcon CNC has an ISO 9001 certification and is FDA registered, providing high-quality and reliable Swiss machining solutions in China and beyond.

Quality Assurance & Certifications

All components undergo 100% CMM inspection with detailed reports, including:

Dimensional Accuracy: ±0.001mm tolerance verification.

Surface Integrity: Ra roughness testing per ISO 4288.

Certifications: ISO 9001, ISO16949, FDA 21 CFR Part.

Machine hardened steel, titanium, or ceramic shafts with ±0.0003" straightness tolerances.

✅ Free Straightness Report

✅ Same-Day Quotes

✅ ISO 9001 Certified

"Falcon produced 25,000 hardened steel actuator shafts for our robotics line. Their cryogenic machining eliminated distortion, achieving 0.001mm runout across all units."

– Sophia Chen, CTO

An Auto Inc.

✓ Verified ISO 9001 Project

FAQ

Q: What materials are best for high-load shafts?

A: 17-4PH stainless steel (H900 tempered) and Inconel 718 for extreme durability.

Q: Can you grind shafts to Ra 0.1µm finishes?

A: Yes. Our robotic polishing systems achieve mirror finishes for medical and optical applications.

Q: Do you provide heat treatment services?

A: In-house vacuum hardening and cryogenic treatment available for wear resistance.