Falcon CNC Swiss is your experienced partner in sustainable manufacturing and precision CNC machining for Green Tech. We design and manufacture high performance and durable components for renewable energy systems, energy storage solutions, and alternative energy technologies. From harnessing nature to storing clean energy, our precision CNC machining capabilities will build the sturdy, reliable framework required for a sustainable tomorrow.

Components for Renewable Energy Generation

Our CNC and Swiss CNC machining services are desgined to manufacture product to enable energy generation that can withstand environments and still maintain the precision and reliability energy generation systems require.

Solar Energy Systems

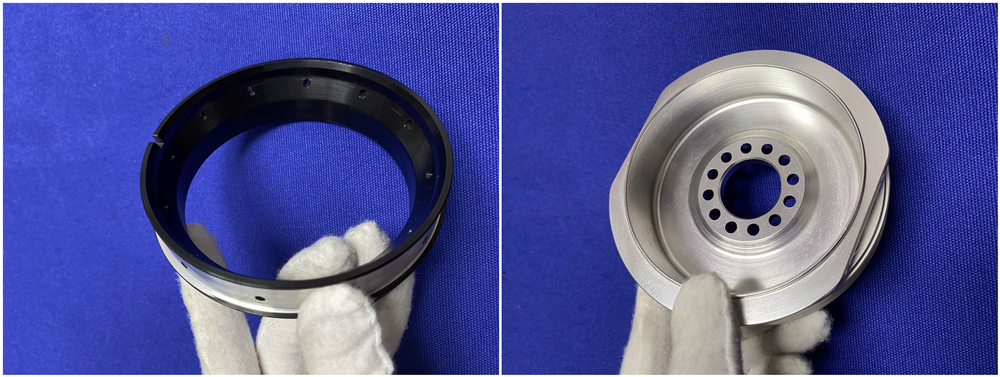

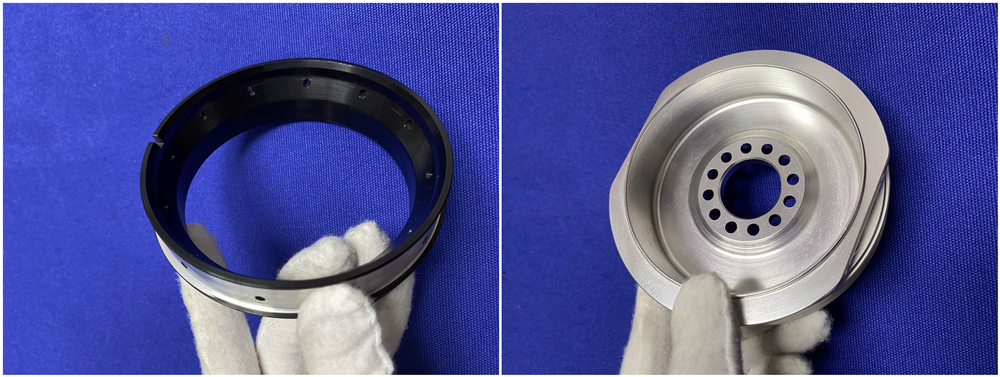

Solar Tracker Parts: Precision machined components for solar tracker actuators, bearing housings, and structural connectors that require weather resistance and long-term durability.

Panel Mounting Components: Solar panel mounting brackets and rail connector components formulated in corrosion resistant aluminum alloys for installation dependability and expected life.

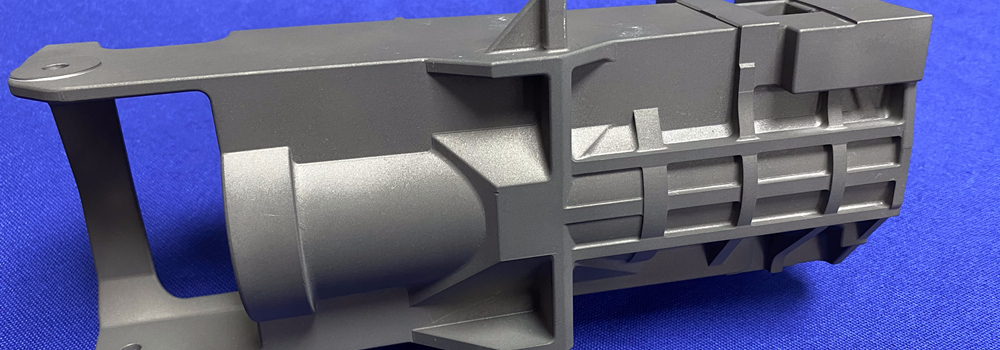

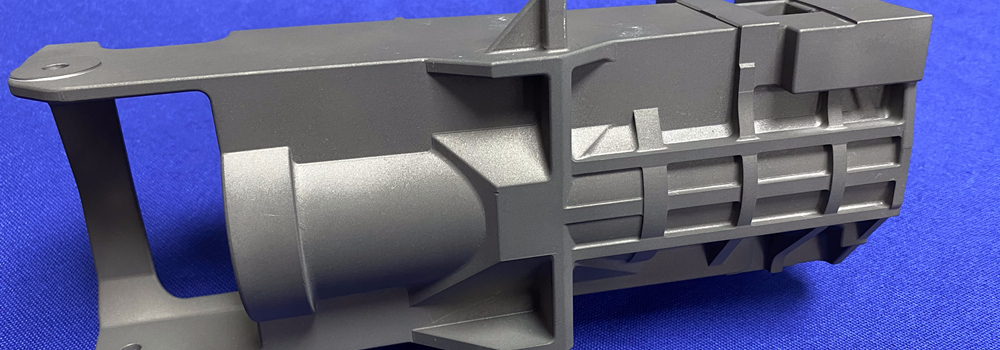

Inverter enclosure parts: Heat sink machining components and protective enclosures for power electronics involving thermal management.

Wind Power Generation

Sensor mounting components: Wind turbine sensor parts and enclosures for condition monitoring systems that provide dependability in high vibration environments.

Blade pitch control system components: Wind turbine components machining for blade pitch control mechanisms requiring exact tolerances and material consistency.

Product components for hydraulic systems: Valve bodies and manifolds for control and braking systems of wind turbines.

Other Renewable Technologies

Hydroelectric components: Corrosion resistant parts for valves, gates, and monitoring equipment in hydroelectric facilities.

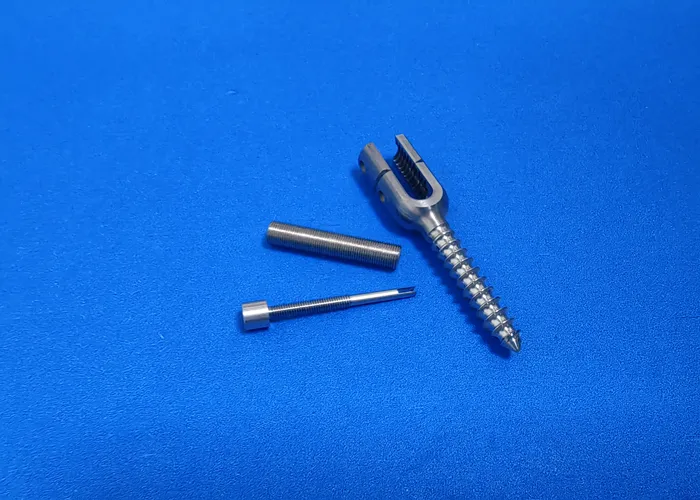

Geothermal systems: High temperature components for drilling and heat exchange equipment facing boiling temperatures, pressure, and hostile underground environments.

Energy Storage & Hydrogen Technology Components

The future of energy will hinge on storage and alternative fuels. We have experience developing products for advanced technologies.

Battery Energy Storage Systems (BESS)

Battery enclosure components: Precision machined battery housings with thermal management pedigree, and EMI shielding properties.

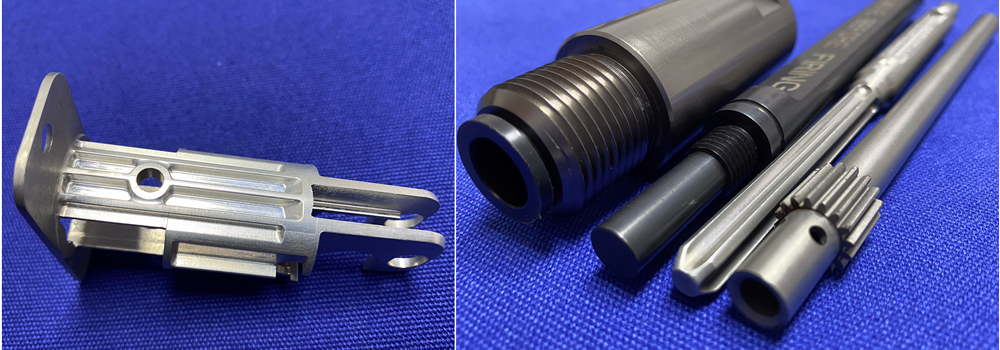

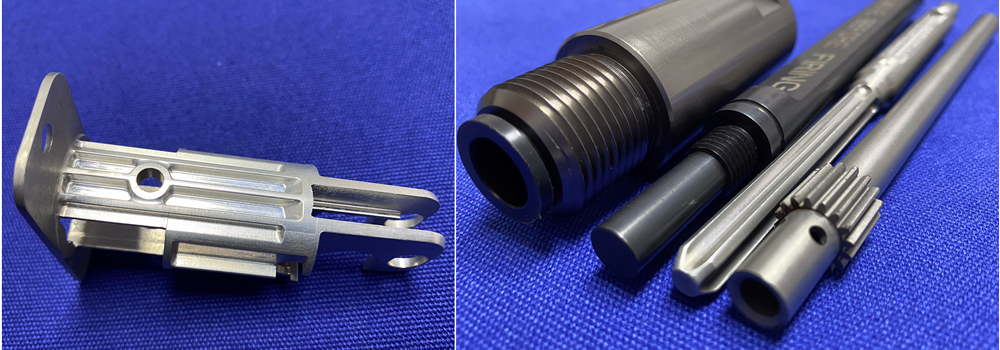

Busbars & Connectors: High conductivity components to ensure battery modules and packs made to tight tolerances perform with their exact electrical properties.

Thermal management plates: Cooling plates machining for battery systems performing liquid cooling to control temperature exposures.

Hydrogen fuel cell systems

Bipolar plates: High tolerance machining for complex geometry hydrogen energy components such as bipolar plates with troublesome raw stock due to added flow field patterns for distributing gas mixtures such as hydrogen and oxygen.

Other stack components: Precision stacked components such as end plates, current collectors, and manifolds requiring compression and sealing systems.

Reformer parts: High temperature components for hydrogen production and processing machinery.

Precision CNC Manufacturing Capabilities for Green Tech

We understand the other worldly requests of energy and green technology applications and have developed a niche specialty to exceed expectations.

Material Selection for Harsh Environments

We know how to machine select materials for demanding applications in energy:

Stainless Steel (304, 316): With extremely extraordinary corrosion resistance for outdoor and marine environments.

Aluminum Alloys: With lightweight consideration and natural corrosion resistance in structural applications.

Copper Alloys: With conductive properties related to electrical and thermal conductivity in energy conversion components.

High-temperature Alloys: For applications with extreme heating in geothermal and energy conversion systems.

Specialized Finishing for Durability

Hardcoat anodizing: To consider all operational aspects for wear resistance and corrosion resistance for aluminum components.

Passivation: To achieve the maximum corrosion resistance when working with stainless steel parts.

Environmental Coating: Coating for UV and environmental protection.

Quality And Traceability

We practice rigorous quality control and provide full material traceability for energy components that require strict reliability and integrity. Learn more about our precision CNC machining technologies for energy and green tech.

Why Falcon CNC Swiss for Energy Projects?

Specificity of Industry

We understand the technical aspects and challenges involved in energy systems (thermal management, environmental durability, etc...).

Technical Input

Our engineers provide material and Design for Manufacturability input to make your components fully optimized for success in energy applications (performance, cost, manufacturability, etc...).

Resiliency

We can support the successful evolution of your project from initial prototype development to high volume production.

Power forward with components made for sustainability and performance. Falcon CNC Swiss is your partner for energy and green technology manufacturing needs. Request Your Free Quote for Precision Energy Storage System Parts and Green Tech Components Today!

Frequently Asked Questions (FAQ)

What materials are best for outdoor solar applications?

Typically, aluminum 6061 with appropriate anodizing is best for solar mounting applications (great strength-to-weight ratio, affordability, low corrosion rating, etc...)

Can you machine components for high-pressure hydrogen applications?

Yes, we machine fuel cell and other components, from certifiable and acceptable materials capable of working within hydrogen service, that maintain tolerances for leak-free performance of high-pressure/gas service.

Do you supply corrosion resistant finishes for marine energy applications?

Yes, we provide passivation for stainless steel, hardcoat anodizing for aluminum, and offer advice on many different coatings to evaluate application and marine environments for offshore wind and tidal energy applications in particular.

How do you provide quality for critical energy components?

We have an inspection plan that typically consists of first article inspection, dimensionally validating all parts as required and certifying all material used, all to make sure the component meets the expectations of the energy industry and market.