Falcon CNC Swiss is a leading manufacturer of high-performance CNC drone parts and custom drone frames for the fast-evolving UAV industry.. It is proven that performance in drone flight, relies on a precise blend of lightweight, strength and accuracy. Our CNC machining services emphasize making reliable, strong and lightweight components for commercial, industrial and recreational drones to optimize flight performance, payload capacity and durability.

Important Systems For Drones We Manufacture

Every gram counts when you are in a aerial systems business. Our focus at Falcon CNC Swiss is mass amount we can machine components which avoid mass and maintain strength and precision required to ensure stability in flight and operation(s).

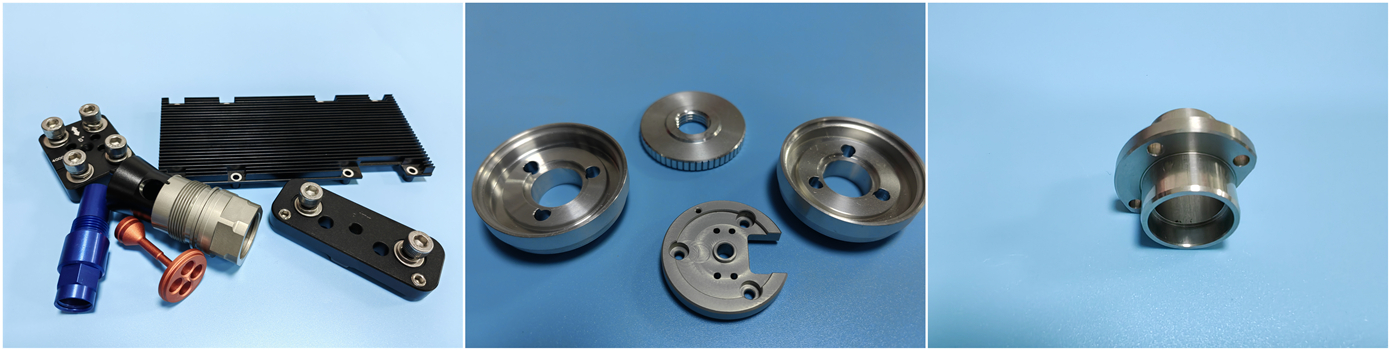

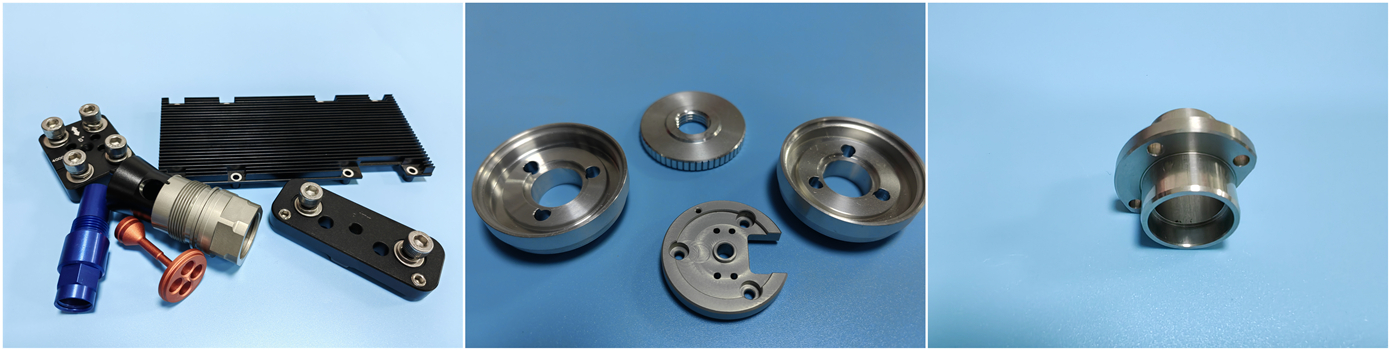

Here are our CNC drone parts:

Custom Drone Frames And Structural Components

Drone Arms & Booms: Precision machining aerodynamic arms manufactured for aerospace-grade aluminum and machined to precision to hold rigidity, while eliminating excess mass.

Custom Drone Body: The main structure made for mounting motors and electronics.

Landing Gear: Light landing gear parts that lessen impact and provide support for stable landing.

Motor And Propulsion System

Motor Mounts: High precision mounting parts for motors maintaining absolute alignment which ensure maximum thrust efficiency and minimum vibration.

ESC Mounting Plates: Thermal management components for heat dissipation from electronic speed controller (ESC).

Propeller Adapters: Introducing balance components with the most effective transfer of power to allow systems to fly smooth.

Gimbal And Payload Systems

Gimbal Mounting Brackets: Mounting brackets that introduce no new vibrations into a camera stabilization system which requires absolute certainty of no jiggle shots.

Payload Housings: Custom housing and enclosure systems specifically manufactured for sensors, camera, delivery systems and LIDAR.

Antenna Mounts: Process that allow for precision brackets components to stay as part of critical communication, for safety, but also provide no loss of transmission signal.

Our Drone Specific Manufacturing

We leverage advanced machining processes based on understanding aerial platform requirements.

Lightweighting for Custom And Metal Drone Frames

We implement advanced methods in design and machining processes to minimize unnecessary mass for a component's system while ensuring adequate structure integrity is achieved:

Use of topology optimization analysis

Material Removal in non critical areas for both lever or component where feasible

Using thin-wall machined processes to lessen mass

Vibration Damping And Management

We know vibration meaning in terms of flight and performance imaging:

Precision balancing of rotating components

Recommendations for a vibration resistant bag design

Use of isolation mounts for sensitive components

Rapid Prototyping And Iteration

We can help you move as fast within the rapid pace of the drone industry as you need to:

Validate your designs quickly by putting in a quick turn for prototypes

Provide Design for Manufacturability (DFM) advice quickly

Fast iterate either product improvements or revisions

Materials Used For Direct Use of Drone Applications

We specifically machine materials that satisfy the highest strength to weight ratio on the market:

Aluminum 6061-T6 : The industry standard as result of considered machinability with good strength v. weight ratios.

Aluminum 7075-T6: When weight is paramount, and strength is maximized as this is a material that is infamously strong. A go-to for high performance drone racing crafting.

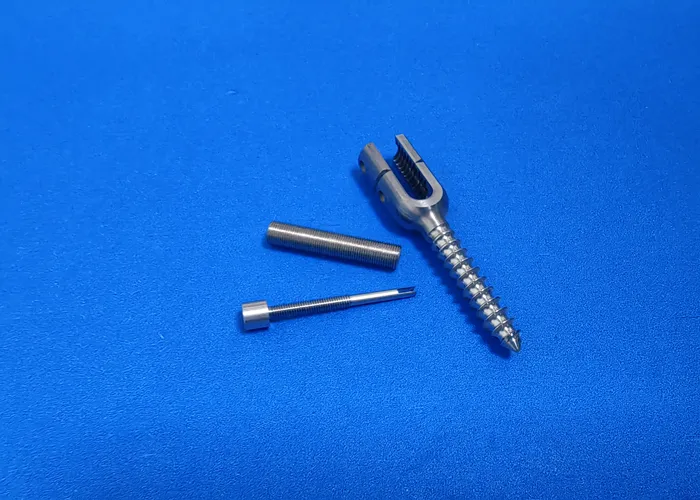

Titanium (Grade 5): Applications that require strength with weight fatigue.

Magnesium Alloys: A extreme lightweighting possibility - as aerospace application continues to blossom, there is a specialty types of application as they mix mass weight with size.

Engineering Plastics (PEEK, Nylon): An avenue that allows for electrical insulation and vibration damping.

Why Choose Falcon CNC Swiss to Machine Your Drone Parts?

Understanding Industry

We understand the drone engineering speak, while wrestling through complex challenges of aerial systems or drones with regard to stability, vibration management, aerodynamic efficiencies, and weights utilization.

Performance Precision

We routinely maintain tolerances of ±0.0005" (0.0127mm) or better will provide assurances of fit and function of every component is certain to preform on fit and function of all components on performance and ultimately stability in the air.

Scalable Manufacturing

Whether you are a startup or a well-established manufacturer, we can help you through the entire process from prototyping to low, medium, and high volume production with our outstanding CNC machining and Swiss machining capabilities.

Quality Control and Assurance

We have stringent inspection procedures at Falcon CNC Swiss, to make sure that each component meets the specifications needed to ensure reliable drone operation.

Take your drone design to the next level with precision machined drone parts. Work with Falcon CNC Swiss for manufacturing that has your UAV flying at an altitude you never thought possible. Request Your Free Custom Drone Parts Quote Today!

Frequently Asked Questions (FAQ)

What are the tolerances that are required for motor mounts?

Motor mounts require very tight concentricity tolerances (typically 0.0005" or closer), to ensure that the motors are perfectly aligned with the other components. This is important to maximize thrust and efficiency and minimize vibration on the drone.

Can you help me minimize the weight of my drone design?

Yes! Our Design for Manufacturability (DFM) feedback can help you look at weight reduction across several strategies: material choice, specific wall thickness, and removing material in the right locations

What are the best materials for racing drones?

When comparing materials for racing drone components, Aluminum 7075-T6 typically offers the best balance of weight and strength because it has a high amount of flexibility, just enough to withstand crashes while limiting drone weight.

Do you offer anodizing for the drone parts?

Yes! Falcon CNC Swiss offers color anodizing (Type II) for looks and durability. We also offer hardcoat anodizing (type III) for durability and wear resistance on items like landing gear and pieces of frame structure.