Introduction: Why Brass Dominates in Swiss Screw Machining

In small batch, precise screw machining, brass stands out as the material of choice for engineers and manufacturers alike. At Falcon CNC Swiss, we’ve learned in the trenches of the shop floor that for complex, small diameter child parts, nothing seems to fit better into the Swiss screw lathe ecosystem than brass. Why has brass come to reign in this domain? In this guide, we’ll adopt a practical engineering perspective to demystify the reasons for brass’s preeminence, its particular applications, and offer some practical tips on making your next custom brass Swiss machining project a total success.

The unique properties of brass along with the inherent stability of the Swiss screw machine combine to create a perfect pitch for small run parts. Whether you’re building electronics brass Swiss machining or a life or death medical component brass Swiss machining, understanding this pitch is key to building a bridge toward cost effective, high volume manufacture of perfect parts.

Why is brass the ultimate Swiss screw machining brass for precise and accurate components?

It all comes down to metallurgy, and how brass behaves when being cut by machining tools.

Three machined features free-cutting: Certain brasses, such as C36000 (Free-Cutting Brass) contain particles of lead blown as the rods are extruded. These act as effective chip breakers, and small grains exiting the tool and clear of the cutting zone and guide bushing are ideally suited to the unmanned, high-speed production of brass Swiss screw machining components.

The powerthirsty brass: Brass machines with less power and less heat than either steels or some aluminums. This reduces wear on the tools, permits increased spindle speeds and feed, reduces thermal distortion—and permits tolerances to be held with regularity and precision.

Cold drawn surface finish: Many brasses have a natural lubricity and yield a grear finish straight off the machine. Frequently no finishing operation is required at all.

This trifecta of benefits translates directly to lower cost per part, extended tool life, and predictable, high-quality output—the core objectives of any precision Swiss machining brass project.

Choosing a Brass Alloy for Your Swiss-Turned Part

Not all brass is appropriate for you. Heading to the right choice of alloy is the first major step; of course you will be assisted by your Swiss machined custom brass provider. Check out some options below.

C36000 (Free-Cutting Brass). Swiss machining royalty. Best possible machinability (100%). Default for virtually all of your Swiss turning brass parts including connectors, fittings, most complex mechanisms where productivity is key.

C26000 (Cartridge Brass). More copper gives cold workability and adequate resistance to corrosion. Good but not at the level of C360. Lathed out for items that might need bending or forming later.

C46400 (Naval Brass). Nice tough strong, and corrosion resistant wellful (due to the healthy plot of tin). Swiss machinable, but tougher and harder than free cutting. Need some different settings. Mainly relevant as plumbing brass Swiss machining components meeting the rough side of life.

Engineer’s Choice. In that ideal world where you need to plan the whole of your Swiss lathe machining brass regime, start with C36000. Certainly, only go off this if some very special property (perhaps corroding seawater if you are machining naval parts) makes this a “highest priority” property that beats the potential productivity cost of not using C360.

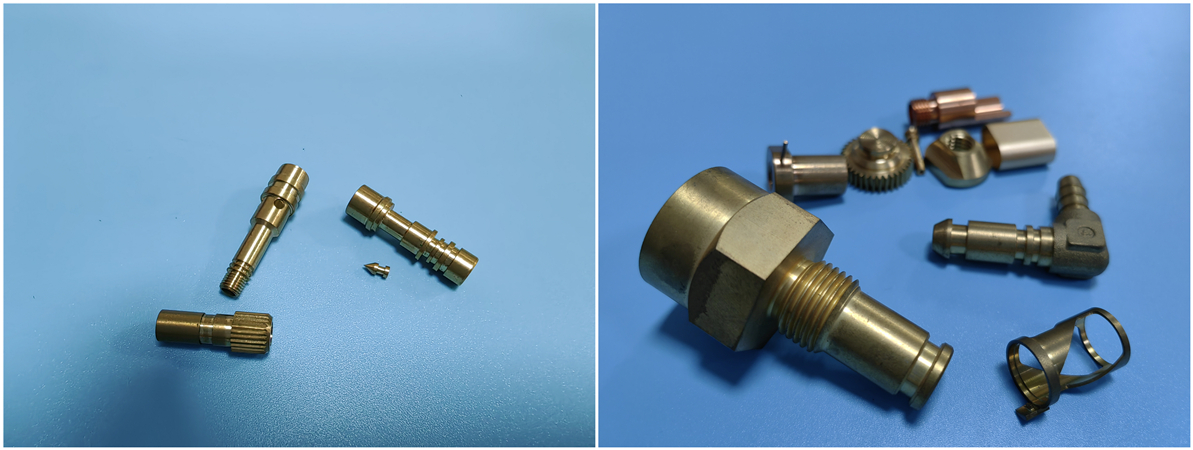

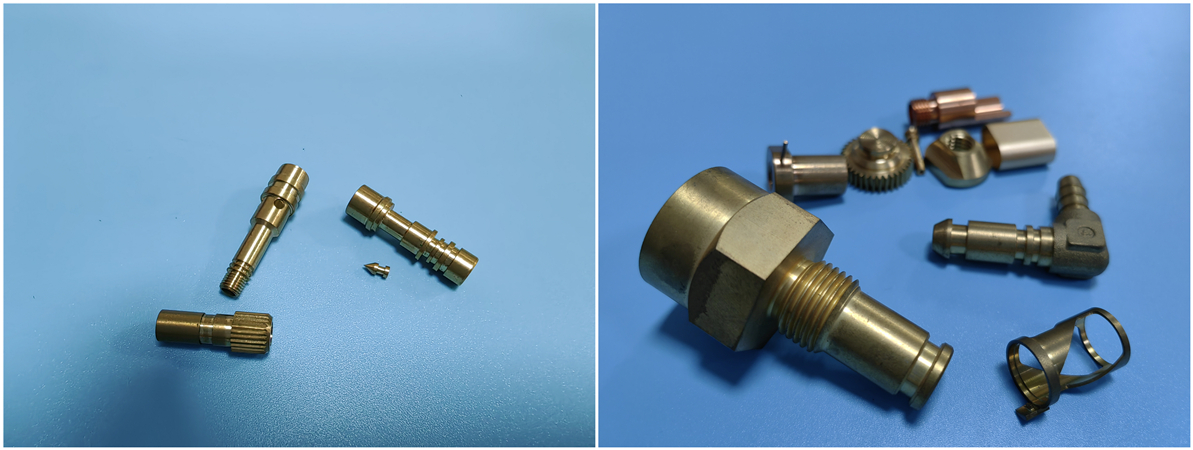

Critical Applications: Brass Machining Domains

Tight tolerances and limited waste offered by swiss machined brass tackle problems that matter to manufacturers.

1) Medical & Dental Device Components

Medical brass Swiss machining finds exploitation in medical, dental and diagnostic applications not only for good machining to complex form, but also ease of sterilization. Examples might include:

Pin-point surgical instrument components

Connectors and housings for diagnostic equipment

Dental instrument components that require fine finish.

2) Electrical & Electronic Connectors

Brass is once again the backbone of electronics brass Swiss machining applications, with the added twist, or pinch, in tiny threaded or slotted connector parts born of swiss lathe tolerances.

Precision pin connectors, sockets, terminals

RFI/EMI shielding

Miniature conductive housings, busbars.

3) Automotive Fuel & Safety Systems

Brought to you by automotive brass Swiss machining parts, because when reliability under pressure really counts, that’s what you can depend on.

Fuel injection components (sensors, connectors)

Pneumatic or hydraulic fittings for braking or drive train use

Valve cores, pressure relief.

4) Plumbing & Fluid Control Fittings

Easy to machine brass gets turned into plumbing brass Swiss machining components for use in plumbing applications, where corrosion resistance is essential.

Precision valve bodies and stems

Compression fitting nuts and ferrules

Metering jets and nozzles with tight diameter tolerances.

5)Precision Instrumentation & Controls

Instrumentation brass precision machining, where the material is critical in gauges, calibration devices, intricately machined gears, cams and actuators.

Pressure gauge components.

Calibration device parts.

Precision gears, cams, and actuators in control systems.

For most Swiss machining brass applications, explore Falcon's dedicated brass machining expertise.

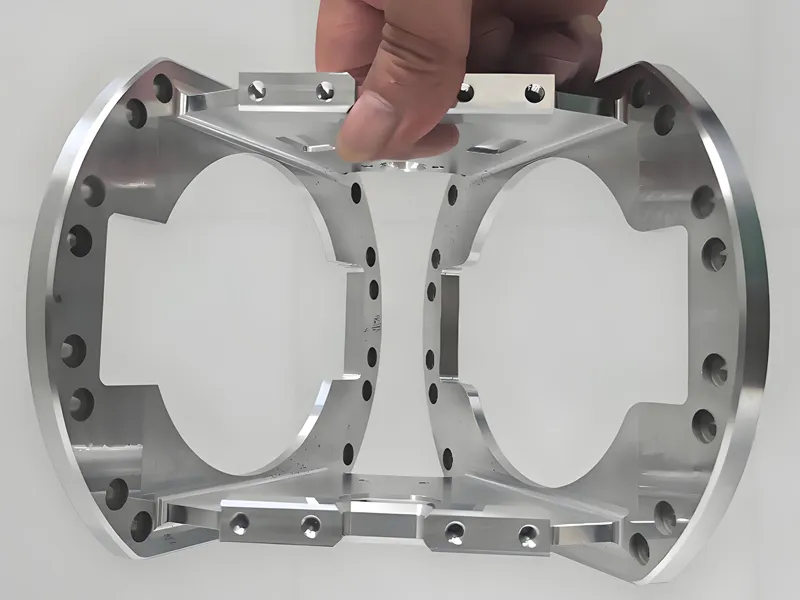

Maximizing the Value of Swiss Machining Brass Parts (DFM Ideas)

To get the most out of your design for Swiss (turning) brass parts, heed the DFM guidelines our engineering team suggests:

Respect the Diameter: Swiss machines are generally most effective cutting parts that have a large ratio of length to diameter; design with the major diameter in mind for the guide bushing.

Watch Out for Deep Holes: Deep holes of small diameter in brass are possible but difficult from the standpoint of chip removal; consult with our engineers when designing a part with holes deeper than 8x diameter.

Specify Tolerances Judiciously: Swiss machines can deliver very tight tolerances; ±0.0005 in. or better is possible, but use only where function mandates. It’s a waste of time and money to specify tight tolerances when close tolerances will do.

Think About Secondary Operations: Brass parts usually have no finish requirements, but if plating (nickel, chrome, passivation), or other coating, is specified, let us know early. Likewise, our Swiss turning services are well-integrated with secondary operation services.

Work with Engineers for Your Swiss Machined Brass Parts

Everyone wants to find a good machine shop when they look for a partner in a project. Instead, you should look for an engineering partner. At Falcon CNC Swiss, we apply decades of materials science experience together with our latest technologies.

Swiss-Turn Platforms: Our multi-axis Swiss-type lathes with live tooling and Y axes have the capabilities to complete most complex Swiss turning brass parts in one setup, so they are as accurate as they can be and leave no need for subsequent operations to turn down additional tolerances.

DFM Analyses: We’ll quote your project, sure. But then we’ll educate you on it, too. Our engineers take a look at your designs and recommend ways to get the part to you a bit more easily, at lower cost, and meeting requirements attached to brass Swiss screw machining.

Quality Assurance: From laser micrometres in-process checks to CMM checks at the end of the run of parts, our oilfield brass Swiss machining parts, and automotive brass Swiss machining components meet tight specifications.

Conclusion: Brass and Swiss Machining — A Match with a Record for Precision

The relationship between brass and a Swiss-type lathe is about as good as it gets in precision manufacturing. From the machinability of C360 brass to Swiss screw machines available today, with increased precision, speed, sophistication and sophistication, makes components that power medical, electronic, automotive and industrial technologies.

Success in Swiss machining brass components come with picking out the right alloy, designing for the Swiss process and working with a supplier that is a technical expert, welcoming their insights.