Injection molding is a high-stakes process which relies on the perfect function of product construction, to achieve a successful molding run. A prime example of such minutely engineered and manufactured components are the mold pins; and molded pins to be precise in those of the ejector pin and core pin varieties, which have for function a very important, yet overlooked work. Falcon CNC Swiss a leading Mold Pins, Ejector Pins and Core Pins Manufacturer, understand to the fullest how the efficiency of such pins greatly influences cycle time, efficiency of part design, product durability with respect to the mold itself.

In this guide we will explore the various and interesting features of mold pins including their various functions and differences plus the special manufacturing technique employed which makes a high performance pin from the average run of the mill pins.

What is a Core Pin in Molding?

A core pin is a essential part of a injection mold which is used to create internal features or hollow internal areas in a molded part. A core pin should be thought of as the male part which fits into the female cavity and forms the interior configuration of the molded plastic part.

Core Pin Main Functions:

Creation of openings, holes and females threads: This may consist of through holes, blind holes, or internal features.

Configuration of complex geometries: These pins form the complex internal geometry which is not dictated by the main cavity block.

Control of wall thicknesses: They serve the purpose of occupying internal space and by virtue of that serve to produce the desired thicknesses in the wall section of the injected part.

Without the properly designed and manufactured core pin, parts would have to be made heavy and solid, not possessing the internal complex structures needed for the myriad uses which they lend themselves to such as in automotive and medical component construction.

What is difference between Core Pin and Ejector Pin?

This is a point often confused and rightly so, but it is one of those points of differentiation which is very necessary A good understanding of the difference will help to clarify the position of the core pin and the ejector pin. Both of them belong to the family of essential mold pins, but they have a function and operational period altogether different.

| Feature | Core Pin | Ejector Pin |

| Primary Function | Forms the shape of the part (internal features). | Releases the finished part from the mold. |

| Stage of Operation | Active during the injection and cooling phase. | Active during the ejection phase, after cooling. |

| Contact with Material | In direct contact with molten plastic. | Contacts the solidified plastic part to push it out. |

| Typical Wear | Wear from abrasive materials and high pressure. | Wear from friction and mechanical stress during ejection. |

Simply stated, the core pin makes the part and the ejector pin takes the part out. It goes without saying that for the proper production of a quality molded part, both of these pins have to be made to the highest possible standard of precision and durability.

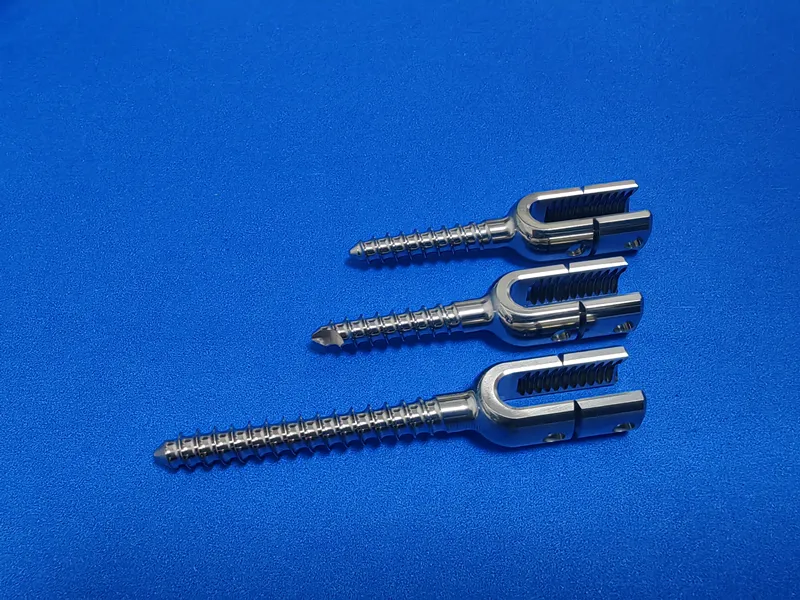

What are the different types of Ejector Pins?

Ejector pins are not of the one type fits all quality. As a specialized Ejector Pins Manufacturer, we produce various types in order to manufacture dextrously the configuration of the part, and the varying difficulty of the ejection process.

Standard Ejector Pins: The commonest variety of ejector pins, these are of cylindrical form with the head. They are used where it is desired to exert the ejector force upon the flat or slightly contoured surface.

Shoulder Ejector Pins: (Sleeve Ejector) A head of larger diameter (shoulder) which by virtue of a large area gives strength and also more stability and effectiveness in the withstanding of large ejector forces which have to be put forth in the case of large molds.

Blade Ejector Pins: Thin and flat profile these ejector pins are of great value where excelling ejector pins are needed to eject parts which for instance contain rib like features or where the round pin would be excessive and leave an ugly scarring effect of the molded part.

D-Cut Ejector Pins: A standard pin with a portion of the cylindrical body but ground flat to form a D shape. This increases the surface area presenting to ejection and serves to eliminate rotating cause of pin rotation.

Core Pins having Ejector Function: In consideration of the varyious demands of core pin designs, one type of pin may serve to fulfill the function of core pin (formings a feature) and the ejector pin (to eject the part) which serves very well to lessen the design of mold complexity for certain applications.

The Timing and Ejection Process

This ejection process is a classic case of mechanical timing and accuracy.

Complete the molding cycle. After the melted plastic is injected into the mold cavity and cooled and solidified enough, the two halves (the cavity side and the core side) of the mold separate.

Activate the ejection system. The ejection system of the mold, a plate that has all of the ejector pins on it, is driven forward by hydraulic cylinders or knock-out bars or whatever mechanism is used.

Have the pins contact the part and exert force. As the ejection plate forces forward, the tips of the ejector pins are protruded through holes in the core side of the mold and contact the injection molded part with force.

Release the part. The pins have uniformly pushed the part, having broken the vacuum seal and any small adhesion to the surface of the mold, and have cleanly ejected it.

Retraction of the system. Before the next cycle is begun, the ejection system retracts, pulling the pins back into their position, clear of the mold surface, thus allowing the process to repeat itself.

Materials for the High Performance Mold Pins

The selection of the material is of utmost importance for both durability and performance. At Falcon CNC Swiss we select the materials based upon the specific requirements of the application, wear resistance, toughness and stability with respect to temperature, etc..

H-13 tool steel. The established standard in the industry because of its great toughness, great wear resistance and great resistance to thermal fatigue. This is most often used for core pins and for standard ejector pins.

SKD-61 (AISI D2). A high carbon, high chromium steel that has excellent wear resistance and a very good material for injection molding of abrasive plastics or high volume production runs.

DC-53. An improved version of D2 that has improved toughness and a lessening of tool chipping, especially useful for the complex and delicate core pin geometry.

Stainless Steel (420, 440C). Mandatory for applications requiring great resistance to corrosion such as for the medical industries or when molding PVC or other corrosive materials.

Carbide. Necessary for the most severe applications working with highly abrasive filled plastics (fiberglass) in which this type provides unmatched wear resistance at a greater expense than introduced.

Surface Finishes for the Enhanced Performance

Now that the precision machined pin has been produced, it must receive the proper surface finish. Surface finishes serve to provide lower friction, greater corrosion resistance and increased life of both the pin and the mold.

Nitriding. A thermochemical method of applying nitrogen to the surface to produce there an extremely hard wear resistant element in addition to excellent anti-galling properties.

TiN Coating (Titanium Nitride). A golden PVD coating that increases the surface hardness of the pins and dimensionally reduces the friction forces to produce smoother ejection and less marking of the part.

Polishing. Most core pins are given a mirror finish in order to produce an excellent surface on the internal features of the injected molded parts and allow easier release thereform.

The Falcon CNC Swiss Manufacturing Process: Accuracy from the Ground Up

As a committed manufacturer of Core Pins and manufacturers of Ejector Pins, we are committed to quality every step of the way in our manufacturing.

CNC Precision Machining: This enables us to achieve extremely tight tolerances (many times within ±0.0002” inch) and perfect concentricity, which is critical element to preventing premature wear and failure.

A Strict Quality Control Program: Every pin is thoroughly inspected. We use sophisticated CMM’s and Optical Comparators to insure that we check every critical dimension, enabling us to assure you of complete consistency from one production run to another.

Expert Heat Treating: We use only certified Heat Treating companies to guarantee that we obtain the core hardness and surface strength that our pins need to achieve maximum life.

Expert Surface Finishes: Our finishing department applies the specified coatings and polishes the pins with expert care to insure you receive a perfect final product, ready for installation.

Optimize Your Mold with Falcon CNC Swiss

Don’t let a small component like a mold pin create major production headaches. Partner with a manufacturer who understands precision, durability and the importance these small components play in your business.

Contact Falcon CNC Swiss today for a quote on your next project. Let us show you the difference that precision manufacturing can mean to you.

Frequently Asked Questions

Q. Can you manufacture custom mold pins that aren’t in the standard catalogs?

A. Certainly, customization is our forte. We can manufacture mold pins to any print you may have, including unique geometries, special head designs and non-standard lengths.

Q. What kind of information do you need from me to be able to give a quote for mold pins?

A. If you will furnish a detailed drawing (CAD file preferred), the specifications for the material desired, the quantity you will require and any additional surface finishes needed, we will be happy to quote the job accurately and quickly.

Q. What are common causes for an ejector pin breaking?

A. Common causes include: misalignment in the mold, insufficient pin strength for the ejection force, faulty heat treatment which may result in brittleness, or fatigue from long term use. Our precision manufactured pins are designed to eliminate failure due to manufacturing defects.

Q. How about your quality as compared to other manufacturers?

A. Our emphasis on CNC Swiss machining gives us an advantage over others in concentricity and tolerancing that is difficult to match. When combined with our strict QC and material expertise, we are able to present mold pins which give superior performance, longer life and greater reliability, thus reducing your downtime and maintenance costs.