The skyrocketing adoption of industrial drone technology is impacting industries all over the map, from agriculture to defense. However, behind every nimble, rugged and highly capable Drone (UAV) lies a foundation of parts that has been manufactured to perfection. The difference between a prototype and a rugged, reliable industrial-level UAV meant for mass production rests firmly on the principles of Design for Manufacturability (DFM) coupled with partnerships with expert drone parts manufacturers. In this discussion, we will look at how the best designers, advanced machining and proven capabilities coalesce to create the next generation of UAVs.

I. How do industrial drone designs benefit from DFM?

Design for Manufacturability (DFM) is the engineering practice of designing products so as to make them more costly to manufacturer. In the case of drone applications where performance is paramount, DFM suits not just as a cost saving device, but as a performance enhancing device. The capable drone parts manufacturer such as Falcon CNC Swiss works with the engineering teams at the very early stages of the design to implement DFM principles:

Selection of Materials: We can recommend optimum materials that will offer a contrivance of strength, weight, and machinability. For example, switching from hard to machine Titanium alloys to high-strength 7075 aluminum for some non-critical structural parts will bring both cost and lead-time down to practically unmeasurable levels, without affecting performance of the UAV.

Simplicity of Design: Complex, single-piece parts can almost invariably be re-designed in to simpler, better made, and easier to machine, replace and maintain, multiple piece assemblies, thus avoiding in many cases complex (and costly) 5-axis machining where simple 3-axis machining will suffice.

Standardization of Features: By using standard tool sizes for holes, radii and threads, the need for custom tooling is obviated, production costs reduced and speed to manufacture markedly improved.

Design for the Process: By understanding the limitations and advantages of CNC machining and Swiss turn lathes, we can recommend design modifications eg slight drafts or wall thicknesses that will produce better quality and yield for the finished part.

By taking DFM into consideration, the final design can be produced for efficiency rather than simply innovation.

II. What are the industrial applications of parts manufacture for UAVs?

The manufacture of industrial production parts for UAV’s brings with it a unique set of problems that mark the differentiation between the hobbyist implicities of manufacture and that which is professional and trustworthy.

The Ratio of Strength to Weight Imperative: Every gram counts with a UAV. The basic difficulty lies in the manufacture of parts that possess great lightness of construction together with great strength of structure to withstand the effect of vibration, possible impact and stresses of load carriage. It requires an extensive knowledge of materials coupled with intensive machining ability to be capable of the removal of every needless micron of material without impairing the structure of the part manufactured.

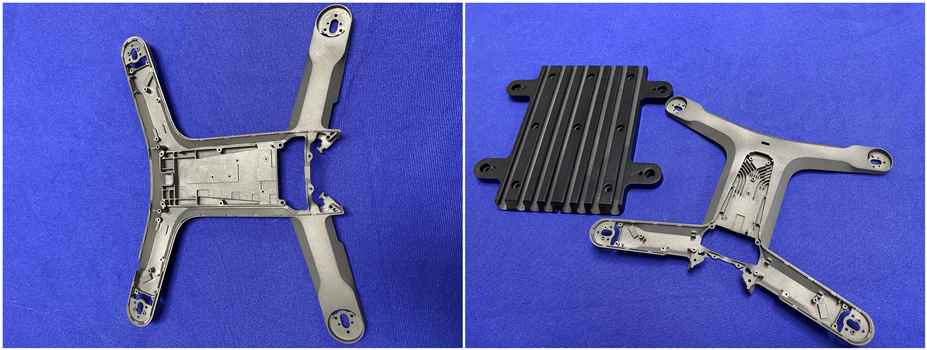

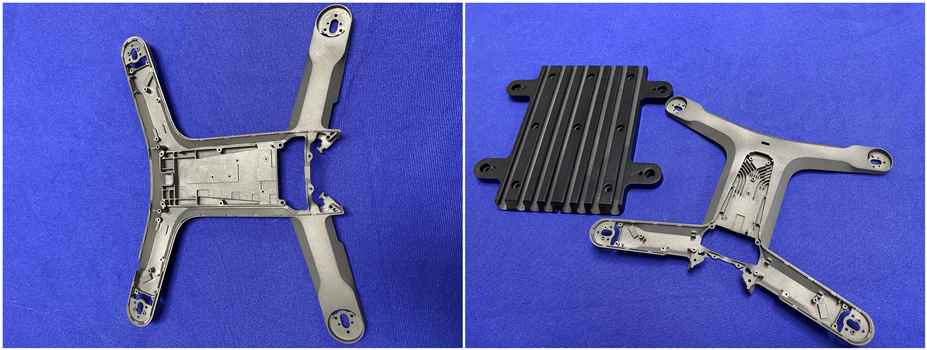

Complexity of Shape and Tolerance: UAV component parts generally speaking, such as motor mounts, arm-brackets and housings for flight-control systems, are required to have very intricate shapes having thin walls and internal channels. To make them difficult of access and impossible to machine results in holding tolerances often necessary within ±0.025 mm or less for proper alignment, vibration-damping and eventual in-flight stability.

Knowledge of Materials: Drones have a wide range of materials utilized, from lightweight Aluminum and Titanium, to advanced composites and engineering plastics. It is necessary for the proficient drone parts manufacturer to be fully conversant with the machining of these various materials and have an understanding of how each behaves during the process of cutting or shaping so as to avoid any appearance of distortion, delaminating or tool wear.

Volume Scalability and Consistency: A design that works for ten units must work exactly as well if ten thousand are made. Consistency in quality, size, and performance in large scale runs is a formidable problem that requires to be solved by effective quality control systems and automated operations.

Environmental Toughness: Industrial drones operate in such harsh environments as salt water corrosion for marine work, extreme temperature changes for mapping, and unceasing exposure to ultra-violet rays. Parts must be made and generally treated (i.e. anodizing, passivation) for these environments in a durable manner.

III. A Case History of Making Parts of Industrial Drones

Project: Making a Custom Drone Motor for a High Altitude Reconnaissance UAV.

Urgency of the Client: A project was made for a UAV, developed for high altitude topographic reconnaissance, to find a motor, which was much lighter than the original equipment manufacturer (O.E.M.) part now in use, as well as having greater vibration admittance, to protect sensitive Li DAR equipment.

The Problem: The existing aluminum mounting device was producing a harmonic vibration which, as a result, ruined sensor data. The project was a 30% decrease in weight of the part utilizing heterogeneous damping.

Solution as Precision Drone Parts Manufacturer:

Design and DFM Checking: The metallurgist then recommended the use of magnesium alloy (AZ31B) for its great damping capacity, as well as for its decreased weight as compared with aluminum. The mount was also redesigned to include lattice structures in local areas of non-vital stress to lessen weight still further.

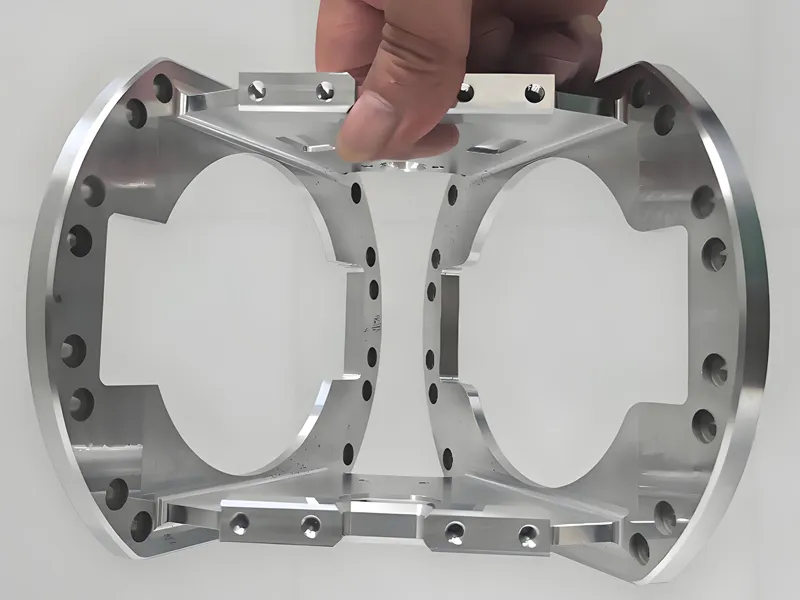

Precision Machining: The difficult shape was obtained by means of machining from a solid loading of magnesium in our 5-axis CNC mills. This required special tooling and coolants to be operated, to facilitate the working of magnesium, which is subject to fire during machining—a tribute to our work done in metallurgy.

Quality Checking: Every aluminum mounting device was machined, inspected 100% upon the CMM so that bore alignment of the motor for turn is guaranteed, as are also the mounting holes. Dynamic balance was also checked to verify the performance of the part under vibration properties.

Effect: The new custom motor mounting device obtained a weight reduction of 35% and is free form 90% of the vibrations which cause harm. This increased the flying rate of the drone by 12% and also insured a maximum accuracy in the data received during the performance of the survey, and satisfying the high demands set forth by the client in standards of performance.

IV. Falcon CNC Swiss (Manufacturers of Custom Drone Parts) capabilities.

As a manufacturer of custom parts to drones the Falcon CNC swiss is equipped for the toughest jobs possible in the components of the UAV fly “business.” Our capabilities are suited for hi-tech, extreme quality and detail required by this line of work.

Advanced Machining Technologies:

CNC Swiss Turning: Ideal for high volume, complex rotary parts, i.e. propeller, hub inserts, connector pins, fasteners of high degree of accuracies of concentricity.

5-Axis CNC Mill Work: To machine complex shapes i.e. mounting brackets camera holding gimbals, structural devices in one diameter set-up, hence complete all in one machining is utilized, to give maximum accuracy and decrease-setting time.

Metallurgical Capability: Extensive numbers of materials worked upon to adapt UAV use:

Light Metals: Aluminum 6061, 7075, Titanium (Grade 2, 5), Magnesium Alloys.

High Tech Plastics: PEEK, UHMW-PE, Delrim, Nylon.

Composite Materials: Composites of plates or sheets used for special purposes.

Servicing: Complete servicing post operational for machining—deburr and carrying out complete post machining process, heat treating, (to increase strength) surface treatment, e.g. types II, III anodizing, nickel plating, powder coating for protective and aesthetic means.

Firm Control of Quality: Our dedication to quality is ironclad. We use Coordinate Measurement Machines (CMM), optical comparators, and surface finish testers to determine that every lot of precision drone parts conforms to the most exacting specifications.

V. Use of Industrial Drones in Various Areas of Application

The reliability of an industrial drone is contingent on the quality of the parts which are manufactured for them. Here are ways in which precision parts enable success in all fields of endeavor:

In Defense & Security: The requirements in durability, signal integrity (for shielded enclosures), and ability in extreme conditions are the highest known, so that they require the utmost in limit testing of drone manufacturers for parts.

In Delivery & Logistics: If the delivery drones are ones, the biggest reliable communications and delivery system is necessary, the means of which are to attain the greatest weight-carrying capacity and the great good of a reliable delivery.

VI. Conclusion

The possibilities of the industrial drone are limitless, while they depend largely on the intricate idea of precision engineering and precision manufacture. The possibility of its progress, from a fine design to a market-leading product, must be dependent on the close industrial relations which we may possess with some manufacturer of parts of drones, possessing great technical ability, its best equipment, and a good comprehension of DFM.

At Falcon CNC Swiss, it is not our business to manufacture parts, but to manufacture the means of expression of inventive ability. We can aid customers in getting safely through the intricate means involved in manufacture of drones to a light structure, a small weight, and enormously reliable delivery mechanism. Contact us today!

FAQ

Q1: What materials do you recommend most commonly for drones?

A. For nearly all parts of construction, 6061 and 7075 Ind. Al. Make best construction both from strength to weight ratio. For very important members of great stresses. Such as landing members, or supports for motors, we make recommendations of Titanium Grade 5. If the important consideration is vibration damping, the use of magnesium or of plastic as in PEEK is superior.

Q2: You can do both jobs of prototyping and high- having production?

A. We surely can. We are prepared to assist customers through the entire life cycle of the product from the initial unfinished prototypes, when the designs are fast, to high triunational operation of continuing or rapid production in the operating part with the certainty of also rapid production by consistent quality.

Q3: What file formats are good for quotation?

A. There are many formats for which one can be prepared, but the best quotes have been furnished only for 3D CAD files in STEP or IGES format with the accompaniment of 2-D drawing for a PDF of the qualities of the critical parts and their tolerances.

Q4: What manner do you have to bring your quality of the machined part?

A. The atmosphere of quality is a transmitted feature. The inspection of process and finality are to have their tests 100% made on critical parts and features using surplus advantage of CMMs and like measuring instruments. We also make our inspection reports for the first article Inspection (FAI) with the idea of enabling our clients to be settled with their requirements and specifications.