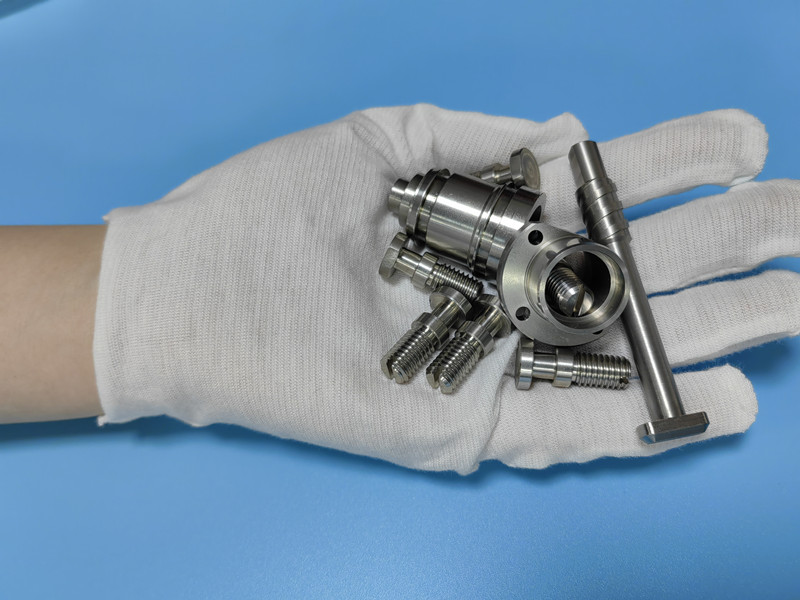

If you’re dealing with something remotely associated to valves or couplings in your business—whether it’s aerospace, medical, or automotive—you understand that precision isn't always simply a nice-to-have. It’s the must-have. And that’s the place Swiss machining comes in. It’s essentially the golden toddler of manufacturing strategies when you’re searching for perfection.

Let’s speak about why Swiss machined valves and couplings are definitely well worth considering. Spoiler alert: They’re extra than simply a incredibly face.

What Makes Swiss Machining Stand Out?

Imagine making an attempt to carve out a tiny piece of rings with a sledgehammer. Messy, right? That’s what ordinary machining feels like in contrast to Swiss turning. Swiss machining is like the use of the sharpest scalpel, the sort physicians desire they had. It’s precise—no, ultra-precise—and cuts thru any fabric like a warm knife via butter.

And, here’s the thing: Valves and couplings? Well, they’re like the unsung heroes of any industrial system. One incorrect move, and it’s like your car’s engine throwing a tantrum. So, let’s get into why Swiss-machined components hold your structures from crashing and burning.

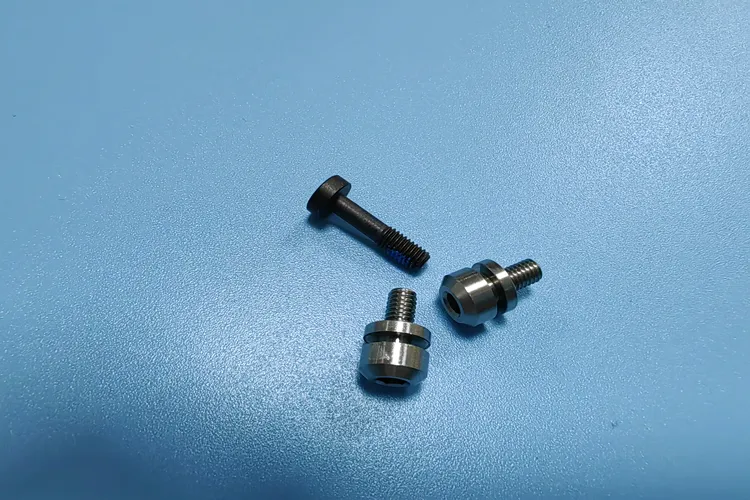

1. It’s Precision Like You’ve Never Seen

Here’s an example: Let’s say you’re constructing a hydraulic system. If the valves aren’t flawlessly crafted, even the smallest mistake ought to reason a leak. Think about it—this tiny mistake ought to purpose a large failure. But with Swiss machined valves, that’s in no way going to happen. Every phase is so precise, it is as if it was once measured with a ruler made of mild itself.

The tight tolerances in Swiss machining are some thing that, let’s be real, most producers solely dream about. The tighter the tolerance, the higher the machine works, and Swiss machining offers you that in spades. Imagine how a lot less difficult existence would be if you should matter on your factors to just… work, each and every time. That’s what we deliver.

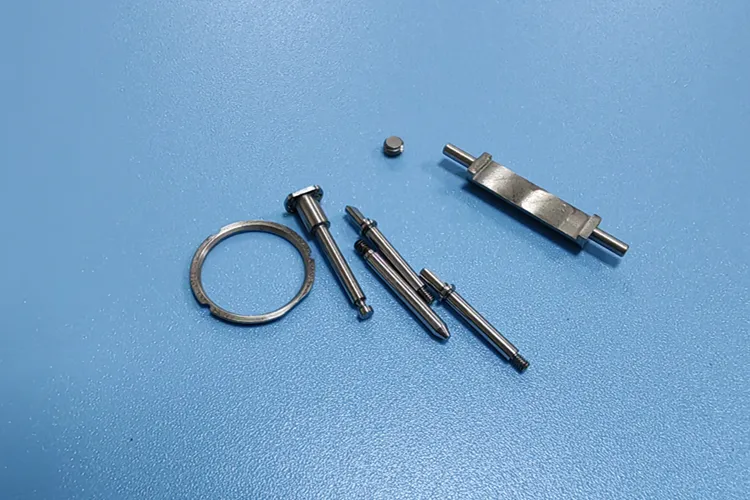

2. Built to Last—Trust Us, We’re Talking Longevity

Let’s be blunt: Swiss machined couplings don’t quit. They would possibly no longer be as glamorous as the state-of-the-art smartphone, however these matters are designed to cope with the hard stuff—extreme pressure, loopy temperatures, even corrosion. It's like the distinction between shopping for a low-priced knock-off and investing in first-class boots for a hike. One’s going to fall apart. The other’s going to raise you thru thick and thin.

For example, I’ve considered these components keep up in locations the place normal couplings would actually buckle. Whether it’s oil rigs, strength plants, or some loopy aerospace project, they don’t returned down. Why? Because they’re made of top notch substances that can take a beating.

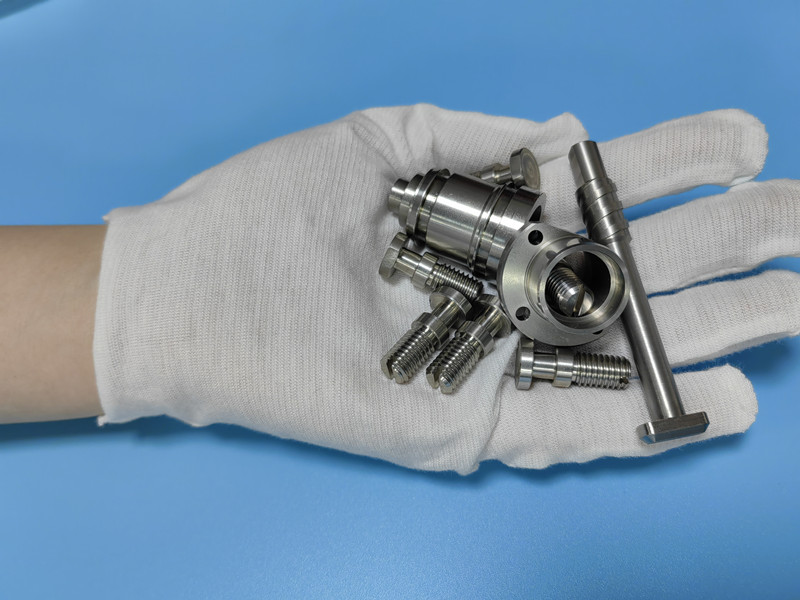

3. Customized Solutions to Your Exact Needs

You don’t continually prefer the identical aspect as every person else, right? Same goes for couplings and valves. Sometimes, you want some thing special, some thing that matches your desires perfectly. That’s the place Swiss machining honestly shines. It’s like getting a custom-tailored suit.

Let’s say you want a valve for a machine that’s bought a excessive strain limit. Most producers will inform you to take a hike, however with Swiss machining, it’s no huge deal. Custom options are essentially our thing. We’ll work with you to create the best in shape for something you need. It’s like a suit made in heaven.

4. Top-Notch Quality at a Reasonable Price

Wait, you would possibly think—precision comes at a steep price, right? Wrong. Swiss machined valves and couplings provide high-quality that normally comes with a hefty rate tag, however we’ve cracked the code. The effectivity of Swiss machining capacity that we can pass by the financial savings on to you besides compromising the quality. It’s like shopping for a Ferrari however at a fee that’s simply a little bit extra than a Honda. Who wouldn’t desire that?

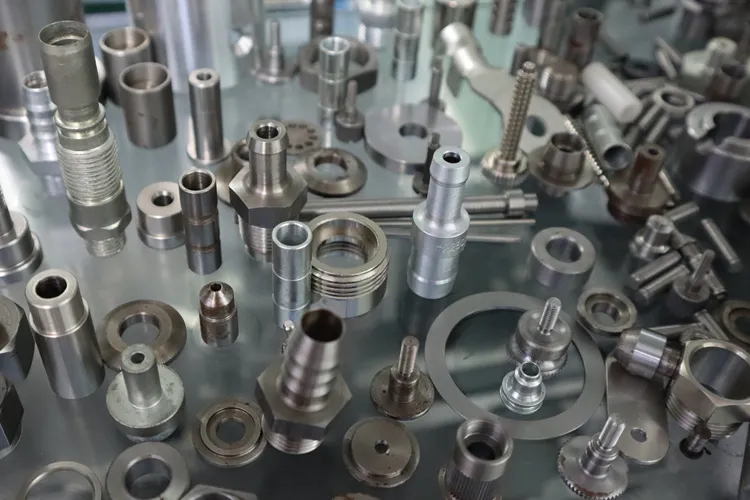

5. Ready for High-Volume Production

Okay, however how about if you want a ton of these? No problem. Swiss machining is all about efficiency, which capacity it’s now not simply for the one-off parts. We can produce excessive volumes of valves and couplings with that identical stunning precision. Think of it like baking cookies: you can make one perfectly, however when you want dozens, you don’t prefer to lose that magic touch. Swiss machining lets you do both.

Conclusion

To sum it all up—if you’re serious about quality, precision, and durability, Swiss machined valves and couplings are the way to go. The subsequent time you’re going through an engineering mission that needs top-notch performance, assume of us at Falcon CNC Swiss. We’ve received the information and the tools to supply precisely what you need, whether or not it’s a customized sketch or a high-volume run.

Trust us—your structures will run smoother, closing longer, and most importantly, you’ll keep away from the stress that comes with subpar components. So, why settle for less? Reach out to us these days and let’s make it happen.