Introduction – Why Stainless Steel is Perfect for Swiss Machining

At Falcon CNC, we deliver precision through Swiss machining made of stainless steel, which offers many advantages for medical, automotive, and electronics industries. Why choose stainless? Its corrosion resistance, strength, and excellent durability hard boil it as the right choice for components that must perform well over long periods. Machining stainless can be tricky, with work hardening and heat generation. That’s why Falcon CNC relies on Swiss machining. Our JCTD32 Swiss machines with integrated CNC turning, bar feeding, and advanced cutting allow for the intricate manufacture of the smallest parts from stainless steel the most precisely.

Advancements and Benefits of Swiss Machine Stainless Steel

Precision and Tolerance

Our precision stainless steel swiss machining results in very tight tolerances, within ±0.005 mm often, for those components which must fit right like a screw used in a medical device or robotics connector. This in manufacturing ensures no variances that impact on product value.

Consistent High-Volume Performance

While other machining methods limit to one or two parts per cycle, stainless steel Swiss screw machining allows for all those parts to be run simultaneously with little worry of variances if built correctly. So how’s that better than turning or milling? Far faster in throughput while fully maintaining product value.

Complex Geometries Made Simple

Components frequently require challenging geometries including fine threads, micro-holes, and/or stepped diameters. Swiss machining handles all these variations with ease. From stainless steel screw machining to the production of complex components, Falcon CNC’s CNC Swiss machines manage this work without requiring an additional operation to meet tight tolerances, saving time and reducing costs.

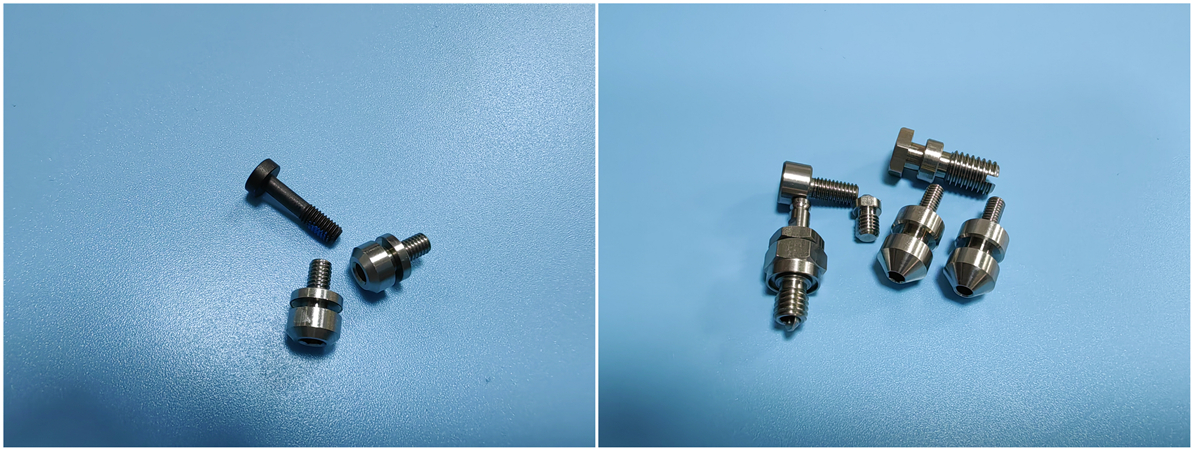

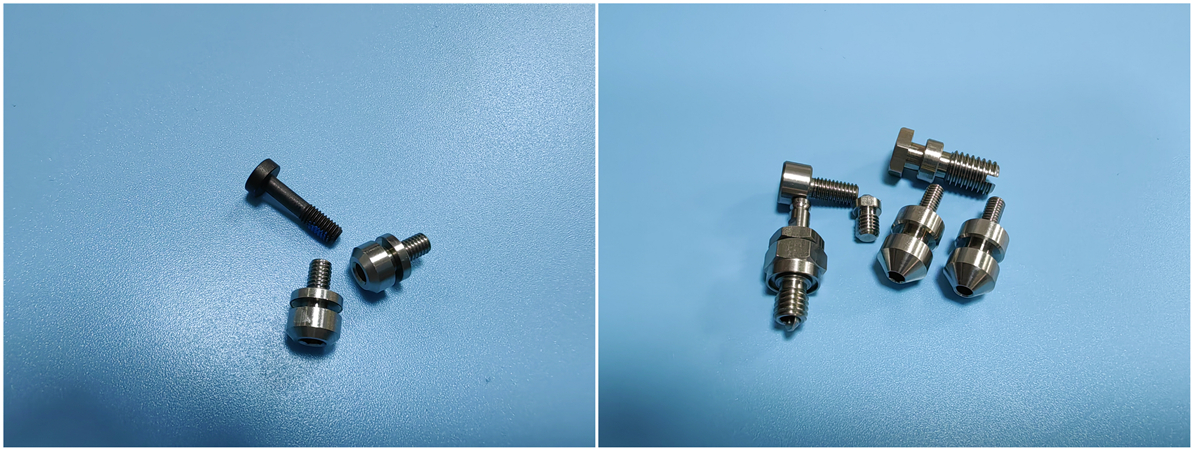

Common Stainless Steel Components Produced with Swiss Machining

At Falcon CNC, we provide a large spectrum of custom stainless steel machined parts including, among other formats:

Miniature screws, nuts, and fasteners.

Precision shafts, pins, and connectors.

Micro components for medical, electronics, and automotive applications.

To learn more about these services, visit our Swiss Machining Services page. All are produced to tight tolerances and reliable performance in even the harshest conditions.

Design and Manufacturing Tips for Stainless Steel Swiss Machined Parts

Material Selection

Choosing the right grade of CNC swiss machining stainless steel components is essential. 304 stainless steel is used for most good applications, while 316 stainless steel resists corrosion better than that for parts destined for medical and marine use. Our team helps clients find the correct grade of stainless steel for their application, balancing price with machinability and performance.

Design Considerations

Avoid excessive wall thickening that can create deformities during machining

Avoid excessive sharp angles and corners without proper chamfers, radii, or fillets for stress relief

Remember tolerancing stacking issues for multi-part assemblies

Get more information on our skills on the Stainless Steel Machining page. Our engineers analyze part designs for manufacturability to ensure every stainless steel Swiss machined part is made to the correct level of precision and performance.

Why Choose Falcon CNC for Your Swiss Machining Needs in Stainless Steel?

When you need expert stainless steel screw machining services, turn to Falcon CNC Swiss. We have the equipment, the people, and the experience to provide service including:

– High tolerance high precision cutting

– Fast turnaround

– Quality assurance check with ISO processes

– Prototyping according to your needs

Get Falcon CNC machining services and and let us save you the headache of high-quality stainless steel components made to last in the toughest applications.

Conclusion – Your Reliable Swiss Machined Stainless Steel Supplier

When you need Swiss machined stainless steel components you can trust, turn to Falcon CNC. From tiny screws to complex multi-featured parts, we deliver the quality and precision you need.

Learn more about our:

Swiss Machining Services

Stainless Steel Machining

Contact Falcon CNC to experience the difference of expert Swiss machining in stainless steel.