One of the most precise CNC manufacturing processes for small, complex and many-tolerance parts, is Swiss machining. As a high precision Swiss machining company, Falcon CNC Swiss provides next-generation CNC Swiss machining services to customers requiring consistent quality at scale.

What does Swiss mean in machining?

In machining, Swiss does not refer to a material, an accuracy grade, or the country of origin, but rather an architecture and related principles of machining made known by Swiss-type machining.

Swiss-type machining promotes a guide bushing, which “holds” the work at a location close to the cutting tool, modifying what we think of being common machine cutting as described below.

Technical characteristics of Swiss End Machine

Guide bushing support: Since the bar stock is supported right at the cutting point, deflection is greatly diminished.

Sliding headstock: The material material slides axially, but is fully supporting in that process.

Extreme dimensional stability: Allows ultra-small diameters and commitments to be machined to tight tolerances.

High concentricity and repeatability: Which is why Swiss machine parts are so important in the first place.

Since the material is “held” continuously, Swiss machinists find it very easy to machine long parts and micro-parts (with a small diameter) without worrying about it deflecting or vibrating off-center as it would on a standard CNC turret lathe. The following are components that make up a normally found in anest pre-processor:

Used in Modern Facilities for:

Medical and surgical parts

Aerospace and drone components

RF connectors and equipment

Automotive sensors and fasteners

The term “Swiss” has become an indication of precision, stability and repeatable accuracy, rather than where the machining takes place.

Why Is It Called Swiss Machining?

In fact, the machine process is named Swiss because it comes from a technology invented in Switzerland to meet the precise requirements that could be met for the demanding watch-foundryware industry. In the late 1800’s and early 1900’s, Swiss watchmakers faced these challenges:

Extremely small parts

Incredibly small tolerances- dimensionally of the order in microns

Long parts, that since they were thin, tended to bend as they were machined

To solve this dilemma, Swiss engineers came up with a new type of lathe that supported the material close to the cutting tool (instead of far back with lots of rotating, erratically changing material unsupported hanging out in space extending from the machine chuck). With the new lathe, machining parts became much more accurate and repeatable.

Why the Swiss design was revolutionary:

Traditional Lathe | Swiss-Type Lathe |

Workpiece unsupported | Guide bushing support |

Higher deflection risk | Minimal vibration |

Limited for small parts | Ideal for micro components |

Lower repeatability | Exceptional consistency |

That name Swiss or “Swiss” machining did become known as such the world over, that is how the subject matter came to be known globally as Swiss or Swiss type machining.

Although Swiss machines today are fully CNC controlled, and today Swiss machining takes place also in China, etc., the name is indicative not of the real geographic location but of a superior design and engineering.

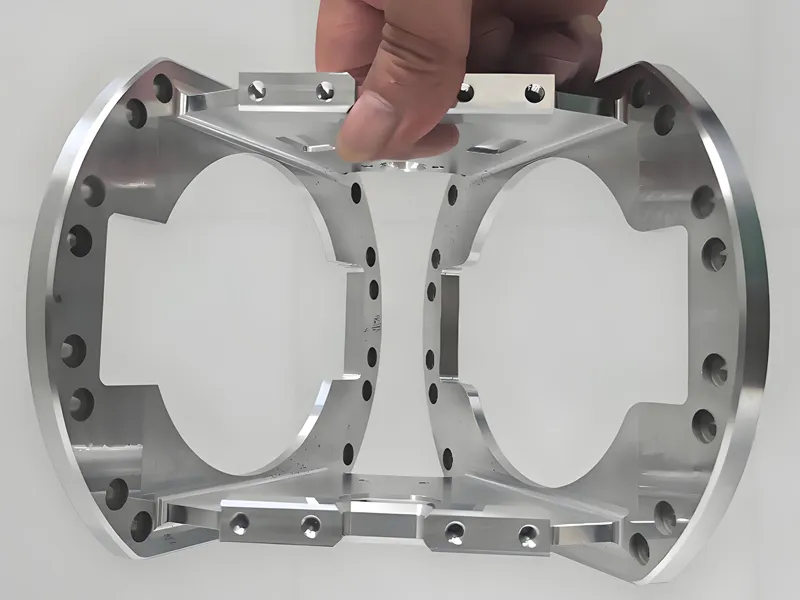

What Is Swiss Precision Machining?

Advanced Swiss precision machining refers to a CNC-controlled system for machining precision Swiss machine parts with:

Tight tolerances (generally ±0.002 mm)

Excellent surface finishes

High repeatability on a large production scale

Suitable for:

Small precision components

Complex geometries

High-volume production with minimal variation

Combine this with a bar-feeding automated Swiss CNC lathe and you have an extremely reliable platform for demanding applications.

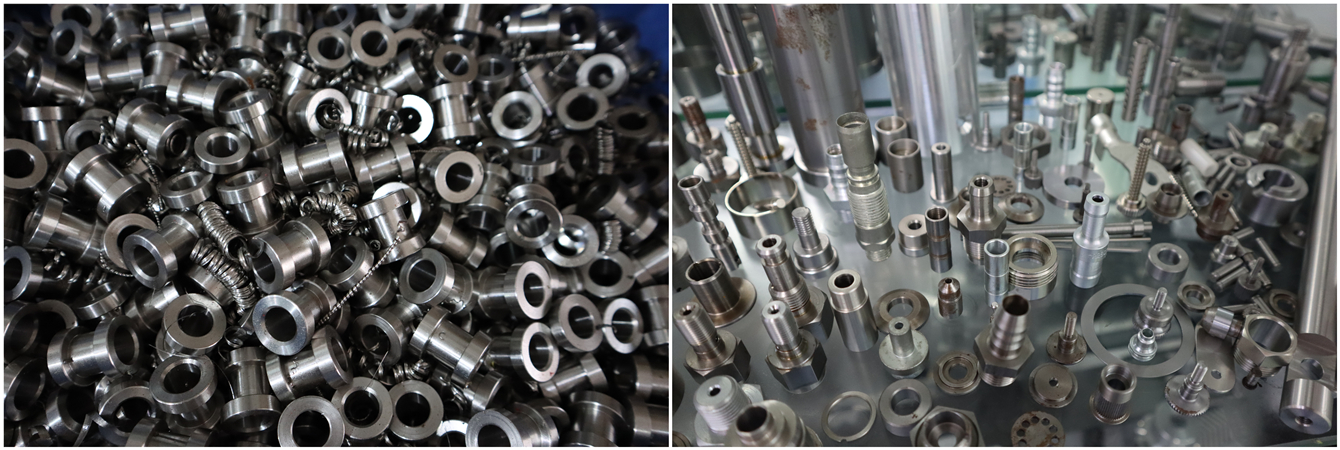

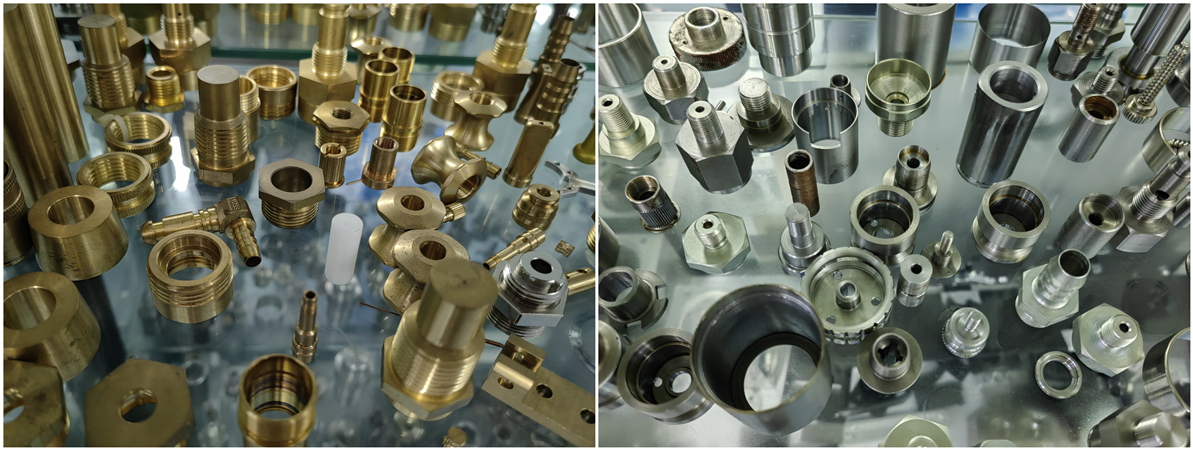

Swiss Machining Services for Small Parts

Swiss machining excels in applications where traditional CNC turning is less effective, such as:

Precision fasteners and shafts

Medical component parts

Electronic connectors and RF parts

Automotive sensor components

With a guide bushing underneath, Swiss machining services for small parts can maintain its accuracies even on parts with prohibitively high ratios of length-to-diameter size, making Swiss machining the best choice for the manufacture of small, precise parts.

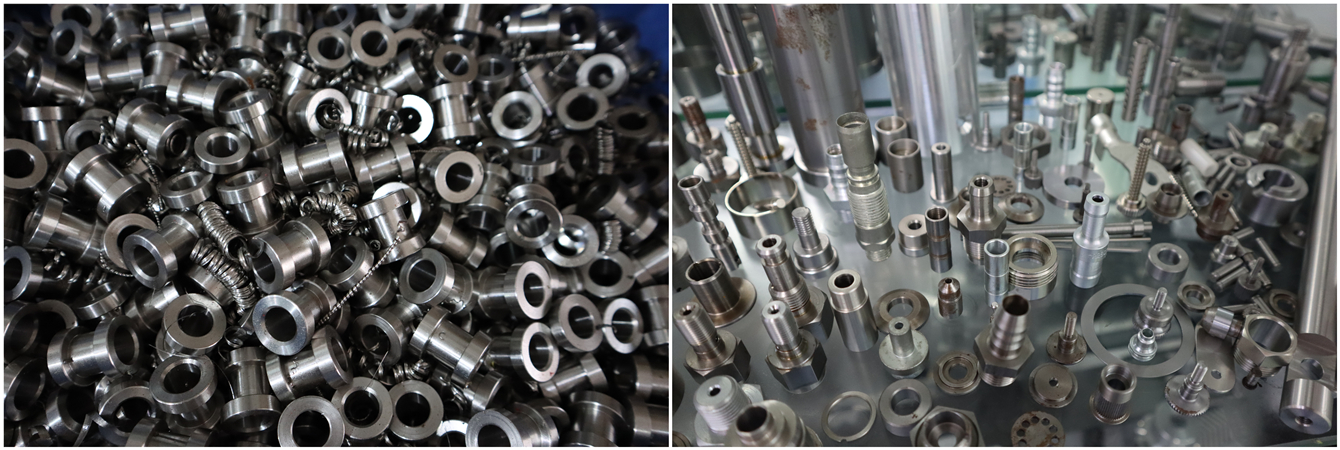

Swiss Machining for High Volume Production

Falcon CNC Swiss is not only a high precision Swiss machining company that does prototypes or low-volume jobs. We also specialize in:

Medium to high-volume part production

Automated bar feeding systems

Quality, consistent results across as many thousands or millions of parts as you may need.

Reason Swiss Machining is the answer for many types of high-volume production

Advantage | Benefit |

Guide bushing support | Superior dimensional stability |

Multi-axis CNC control | Complex features in one setup |

Automation-ready | Reduced cycle time and labor cost |

Process repeatability | Stable quality at scale |

Swiss Machining in China: Precision without Compromise

Swiss machining processes in China have developed quickly as the country moves to offer cost-effective manufacturing without cutting corners using CNC Swiss Machining to achieve results on par with elsewhere in the world.

Falcon CNC Swiss uses:

In this way, we can afford to produce their Swiss machining services for precision parts work the world over in good lead times while remaining competitive.

Why Choose Falcon CNC Swiss Machining Services?

As a CNC Swiss machining services maker, we feel Falcon CNC Swiss stand out because of:

Precision Expertise – Proven ability to get tight tolerances

Small & Compact Capability – Good for micro and slender parts

High-Volume Capability – Consistent quality with repeatable parts

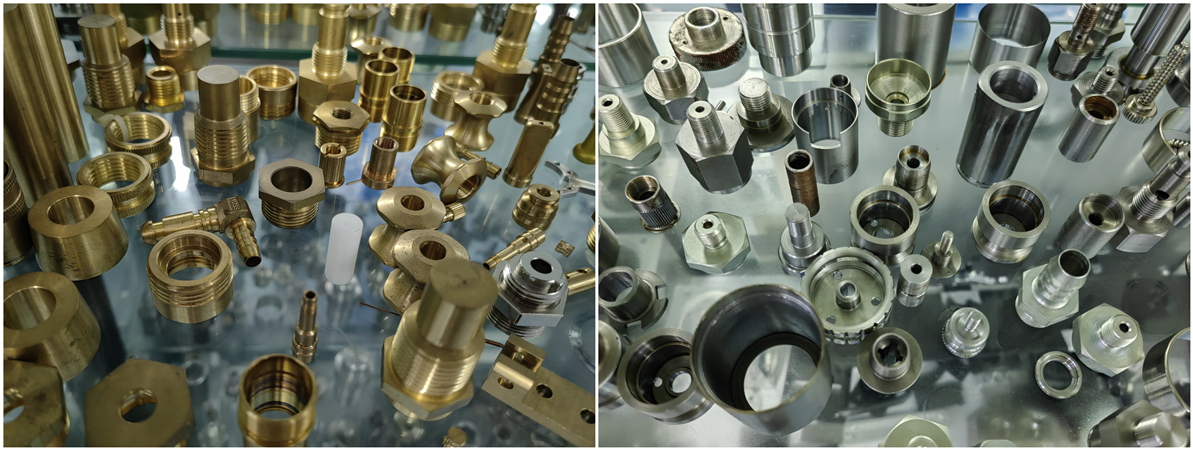

Materials Capability – Aluminum, brass, copper, stainless steel, and more

Support from Engineering – Design-for-manufacturing 101 with Swiss machining

Not just a supplier but a partner in your long-term precision machining. Talk to our Swiss machining engineers about your precision part requirements

Conclusion

Swiss machining isn’t the only method of manufacturing used today. But when it comes to run rates, Swiss machining stands head and shoulders above its competitors. Whether you need precision Swiss machining, or only Swiss machining services?

Explore our Swiss machining services and consider Falcon CNC Swiss for your next precision machining project.