Over the years, Swiss machining has gained a reputable foothold in manufacturing; it has found use in industries requiring extreme accuracy, consistency and volume. As a Swiss lathe machine shop, Falcon CNC Swiss produces high-quality parts via CNC Swiss precision machining and Swiss screw machining for customers worldwide.

CNC Swiss Precision Machining - What Is It?

CNC Swiss precision machining is a specialized method for producing small, complex and high-tolerance components with extreme accuracy. It’s accomplished on Swiss-type CNC automatic lathes, quite different from traditional CNC turning machines.

The key to CNC Swiss precision machining is in the guide bushing; rather than gripping the part at one end, the material is held close to the cutting tool. This prevents significantly deflection, vibration and thermal distortion, making it well-suited for long, slender, and dimensionstically-critical parts.

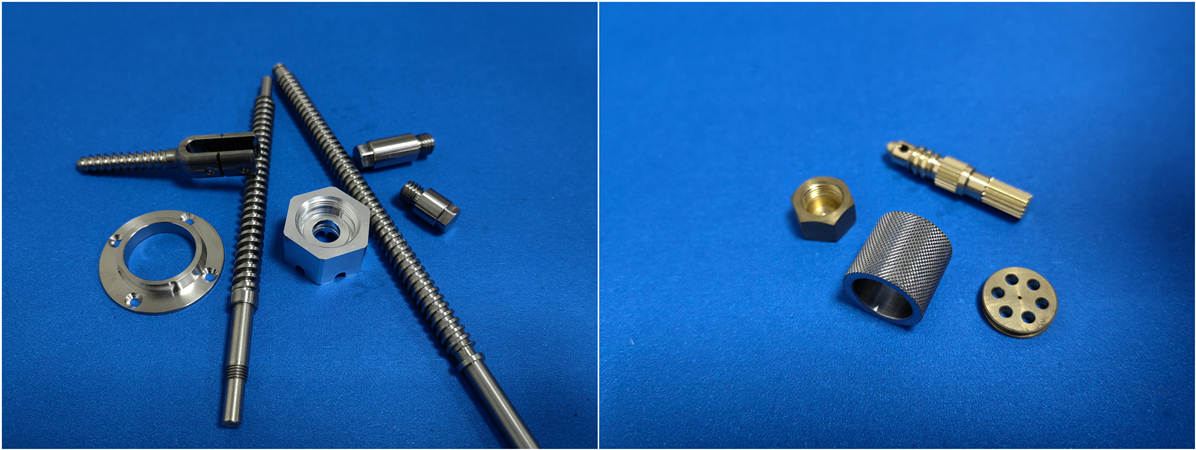

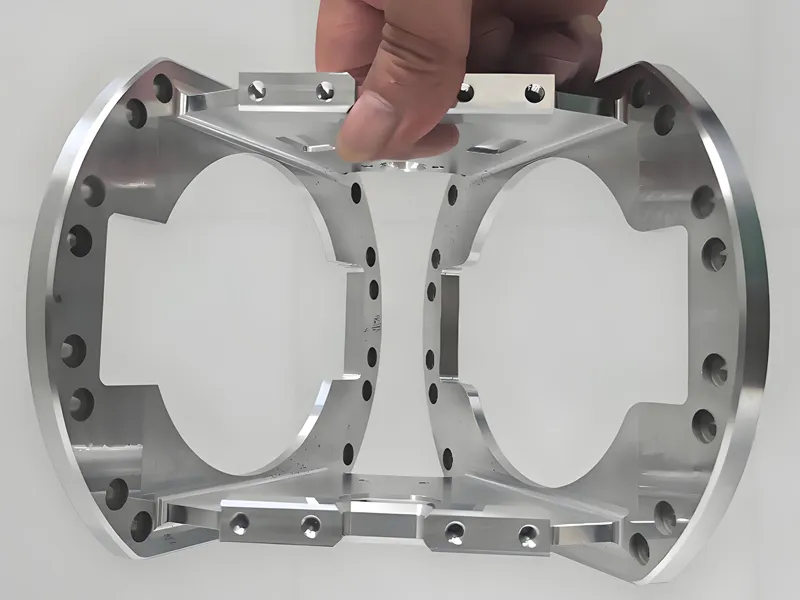

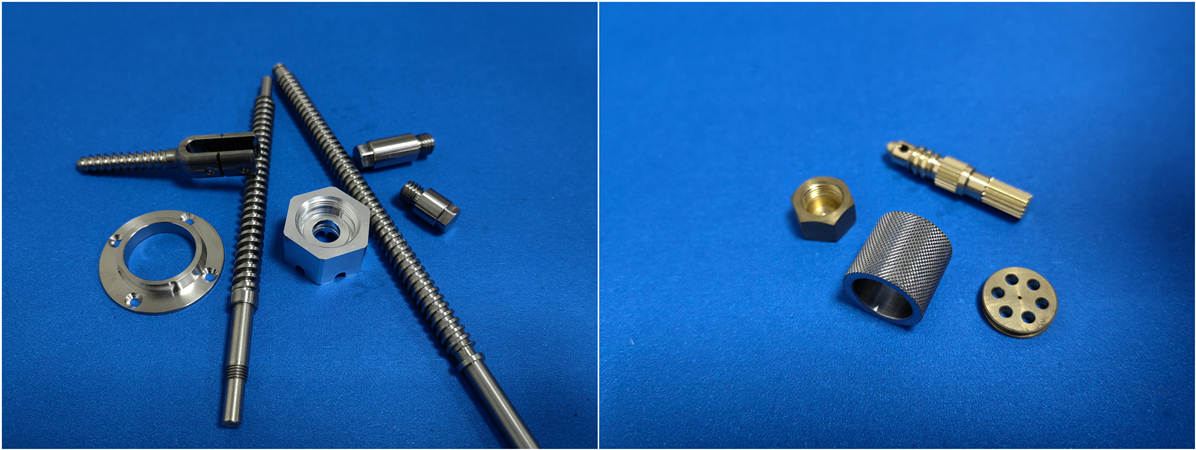

Characteristics of CNC Swiss precision machining include:

Extreme Dimensional AccuracyMinimization of vibration means tolerances as tight as ±0.002 mm are easily attainable. This degree of precision makes Swiss machining appropriate for medical, aerospace, electronics and automotive parts.

Part SynchronizationReducing complexity, Swiss machines undertake turning, drilling, milling, threading and even cross-hole machining all on one machine with one setup, thanks to integrated “live” tooling.

RepeatabilityMultiple identical parts turned repeatedly on CNC Swiss automatic machining insures exact quality throughout thousands or millions of parts.

Material ApplicationsWith its suitability for nonferrous materials of all kinds, CNC Swiss precision machining can be accomplished on stainless steel, brass, copper, aluminum—and specialty materials. These characteristics encourage the use of CNC Swiss precision machining in Swiss screw machine shops and progressive manufacturing as they favor precision, speed, and scalability.

What Is the Swiss Machining Process?

The Swiss machining process goes well beyond normal turning and is a controlled, automatic turning method embraced for its high level of efficiency as well as its precision. Swiss machining is quite different from conventional CNC turning.

Step-By-Step Swiss Machining Process:

Bar Material FeedingThe use of guide bushings along with manpowerless feeding of bar stock directly into machines positions the material very close to the cutting tools.

Guide Bushing SupportWorkpieces are never distant from the point of operation. That means eliminating vibration and improving dimensional accuracy.

Simultaneous Multi-Axis MachiningUsing multiple tools doles out shorter shave time: the Swiss machine does turning, drilling, milling, threading and even grooving all in one cycle.

CNC-Controlled Precision ExecutionSpeed of the spindle, movement of the tool and even feed rate are all controlled with highly accurate programming through CNC.

Automated Cut-Off of PartsFinished parts are separated cleanly with little need for secondary operations.

Why the Swiss Machining Process Matters

Benefit | Result |

Close Tool Support | Superior concentricity and surface finish |

Single-Setup Machining | Reduced cycle time and error risk |

Automation | Ideal for high-volume production |

Process Stability | Consistent quality across long runs |

This process explains why Swiss machining companies and Swiss screw machine shops are preferred suppliers for precision industries where even minor deviations can cause functional failure.

CNC vs Swiss Machining: What’s the Difference?

Understanding the difference between CNC and Swiss machining helps engineers choose the right manufacturing solution.

Feature | CNC Machining | Swiss Machining |

Workpiece Support | Clamped at one end | Supported by guide bushing |

Ideal Part Length | Short to medium | Long, slender parts |

Precision | High | Extremely high |

Production Volume | Low to medium | Medium to high |

Setup Efficiency | Multiple setups | Single, integrated setup |

In short:

CNC machining is ideal for larger or more complex 3D parts

Swiss machining excels in small, high-precision, high-volume components

That’s why leading Swiss machining companies rely on Swiss screw technology for medical, aerospace, electronics, and automotive applications.

CNC Swiss Screw Machining Services at Falcon CNC

At Falcon CNC Swiss we provide full range of CNC Swiss screw machining services:

Precision turning and threading

Cross drilling and live-tool milling

Complex profile machining

Tight-tolerance dimensional control

Our Swiss machines are designed for high repeatability for those customers who depend on CNC Swiss machining for small and high-volume components.

Why Choose a Swiss Lathe Machine Shop Like Falcon CNC?

The choice of Swiss lathe machine shop has a great impact on your product’s performance and success as well as its full cost.

Falcon CNC Swiss Advantages

Advanced Swiss-Type Equipment – Multi-axis CNC swiss automatic machining

Engineering Expertise – Decades of expertise in Swiss screw machining

High-Volume Capability – Reliable production of thousands to millions parts

Material Versatility – Brass, copper, stainless steel, aluminum, and special alloys

Quality Assurance – In process inspection and documented quality control

A dedicated Swiss screw machine shop differs from the regular machine shop in its focus on high repeatability and process stability for long-term production.

Applications of Swiss Screw Machining

Applications for Swiss machining are abundant in industries that need high repeatability and accuracy:

Medical devices and surgical components

Automotive sensors and fasteners

Aerospace and UAV components

Electronics connectors and precision pins

Industrial fluid and RF components

These applications gain and are protected through the Swiss precision machining processes other CNC machining techniques simply cannot compete with. Request a quote for high-precision Swiss machining services now.

Partner with a Trusted Swiss Machining Company

Among the years experienced Swiss machining companies, Falcon CNC Swiss brings together Swiss lathe skill, CNC automation, and engineering-driven manufacturing for precision quality components at volume producing prices.

For work with a Swiss screw machine company you can rely on, for ongoing orders or a supplier of precision parts, Falcon CNC Swiss has the skill and capacity to support yours from design to delivery.