A CNC components factory is only as good as its last order, and for many customers, that’s an order for custom CNC turning parts. As a reliable China CNC turning parts factory Falcon CNC Swiss manufacture custom and OEM CNC turned parts for customers in automotive, medical, aerospace, electronics, and industrial applications.

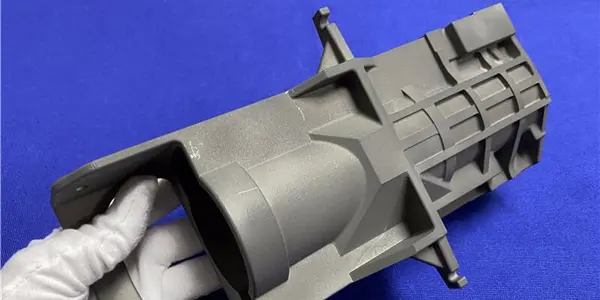

We use our VRD and CNC turning and Swiss machining capabilities so that we can manufacture CNC turning parts for any application in prototype and high-volume CNC turning part manufacturing, without sacrificing quality or reliability.

What Does Turning Mean in Machining?

Turning is the most prominent turning process in material machining, in which a workpiece rotates and a tool positioned accordingly is used to remove material by cutting in order to produce a part of the desired contour.

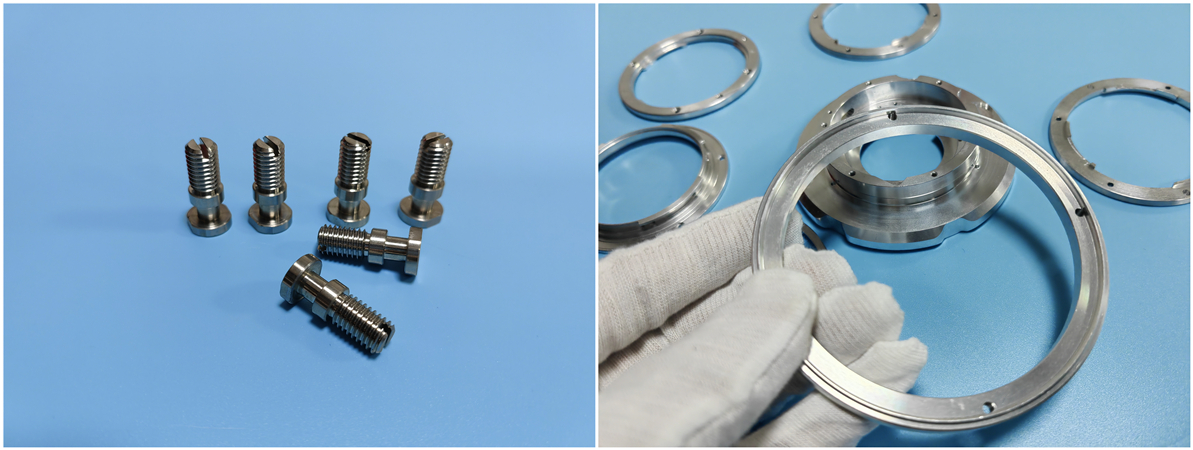

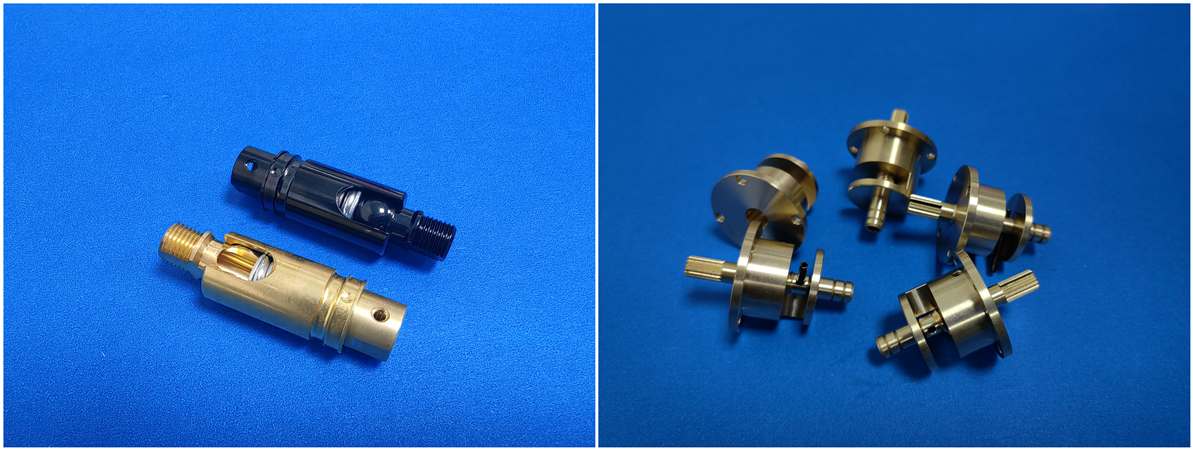

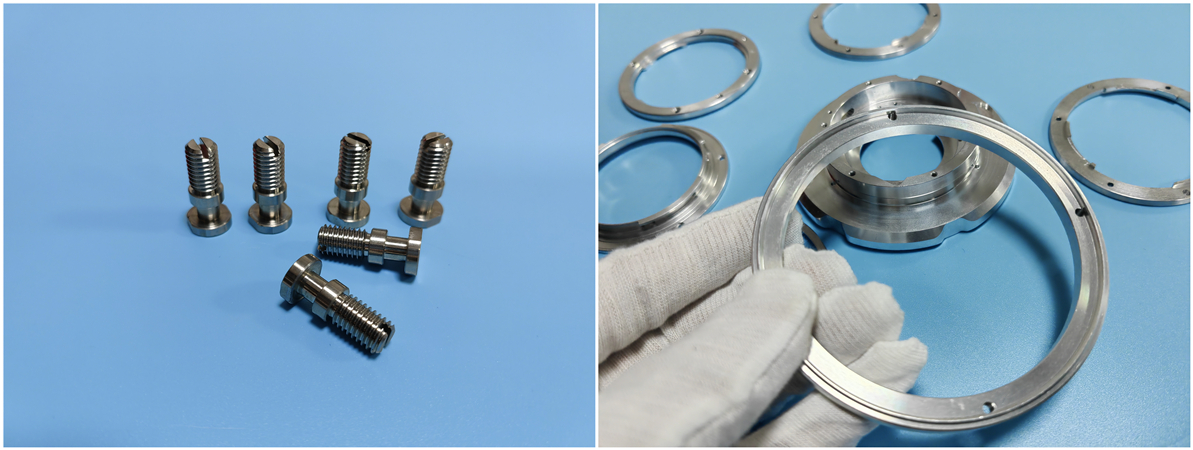

Turning is used to produce key components such as:

- Cylindrical parts, shafts, pins, bores, bushings, fasteners, and so on

- Thread using thread taps and forming tools

- Parts with grooves and other formed features around cylindrical workpieces

Since the tool has to track the direction of the workpiece, the process works very well for parts where centricity and a smooth finish are of utmost importance in any modern precision manufacturing process.

Is CNC Turning a Lathe?

Yes—a CNC turning is a kind of lathe machining, albeit many times more sophisticated and reliant on advanced technology than a conventional lathe operation.

CNC turning is used to control the movement of the tool(s) cutting the part. Rather than manually moving a tool bit, a turner “teaches” a CNC turning apparatus, with multi-lateral and 3D movement, where to move and direction of cutting. Often, there is another variation where the parts is simply moved, and a stationary tool cuts, which is the CNC Swiss turning used for long slender parts.

Traditionally, lathes have relied on controlled manual operation, but CNC technology makes it easily possible to not only track the motion of a lathe tool, but control the path. Newly available CNC lathe turning parts use sophisticated high-precision tools that result in unique parts with very small variation high-quality parts that are ideal for custom CNC turned parts, and OEM orders.

What Is the Advantage of CNC Turning?

The obvious advantages of CNC turning are high precision and repeatability over conventional machining, plus more benefits such as:

- precision tolerances (often ±0.002 mm)

- an inherently faster process with several opportunities to reduce the labor cost accessibility of price info and therefore cutting down the cost/cycle time.

- various materials such as aluminum or brass, stainless steel, and so on may be used.

- growing from prototype units through source with material sources for bulk highvolumeSESprit tends update.

Falcon CNC Swiss: A Trusted CNC Turned Parts Manufacturer

As an experienced CNC turned parts supplier, Falcon CNC Swiss provides end-to-end solutions—from engineering support to final inspection.

Our CNC Turning Capabilities

Capability | Description |

CNC Turning | High-precision turning for cylindrical components |

Swiss Turning | Ideal for long, slender, complex parts |

OEM Production | Consistent quality for large-volume orders |

Custom Machining | Design-to-spec CNC turned parts |

Quality Control | In-process & final dimensional inspection |

We combine Swiss-type machining with advanced CNC turning centers to ensure superior accuracy, surface finish, and production efficiency.

Custom & OEM CNC Turning Parts

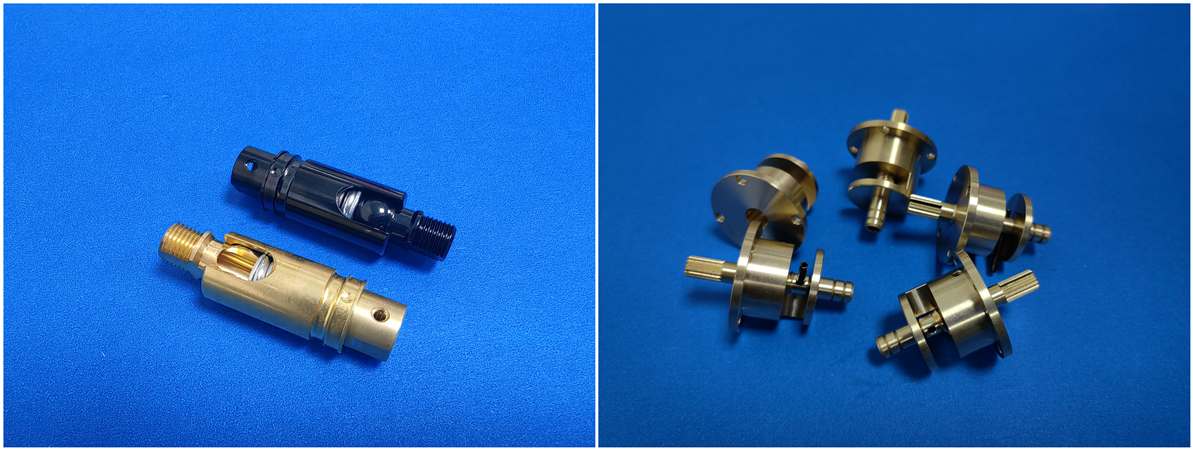

There are numerous potential components manufactured using CNC turning technology, with many producers looking to China for parts manufacturing. Falcon CNC Swiss is a professional manufacturer of:

Custom CNC turning parts produced based on customer blueprints

OEM CNC turning parts for long-term customer project delivery

Fast prototyping for expedited design build

Scalable output for larger production runs

Our engineers help clients develop parts through knowledge and experience, working to see designs optimized without losing useful functionality, while also reducing cost.

CNC Turning Parts Quotes: What to Expect

Since there’s no such thing as a ‘standard’ CNC turned part, seeking CNC turning parts quotes requires some patience. You will quickly learn many factors and decision points go into pricing, among them:

Material type and grade

Required face of CNC part contact, machines needed for part manufacture

Part geometry

Order volume

Secondary operations like threading, drilling and finishing

As a Chinese CNC turning parts factory, we keep our pricing consistent and clear, helping to ensure our customers know what to expect of us ahead of time. Details are of great importance to us.

Why Choose a China-Based CNC Turned Parts Factory?

As a premier CNC factory in Asia, working with a China CNC turned parts factory also comes with costs and challenges. With that said, we believe you’ll find: lower unit pricing, economical machinery and infrastructure, good labor costs, and superior engineering measuring counteract any complications.

If quality CNC part manufacture can be accomplished at a distance, it’s with professionals like those we provide. Far from the trimmings, Falcon CNC Swiss becomes a CNC turning parts supplier for manufacturers worldwide. Whether you need custom CNC turned parts, high-volume OEM CNC turning parts, or a reliable CNC turning parts manufacturer for long-term cooperation, Falcon CNC Swiss delivers precision, consistency, and scalability.

If you’ll need a small quantity of CNC turned high end parts, or if you need just one big CNC turning part, welcome; you’re in the right place. For every other standard CNC part service, from the CNC Turning Center, call for a free quote.