In the modern manufacturing landscape, CNC precision turned parts are vital constituent components for a huge range of industries, from automotive through to medical devices. Here at Falcon CNC Swiss, we specialise in producing precision CNC turning parts with tight tolerances, complex geometries, and consistent quality of parts.

Our advanced Swiss-type CNC turning technology ensures that precision and reliability are never compromised and that the aluminium, brass, and stainless steel parts we produce exceed the industry across the board.

What are Turning Parts?

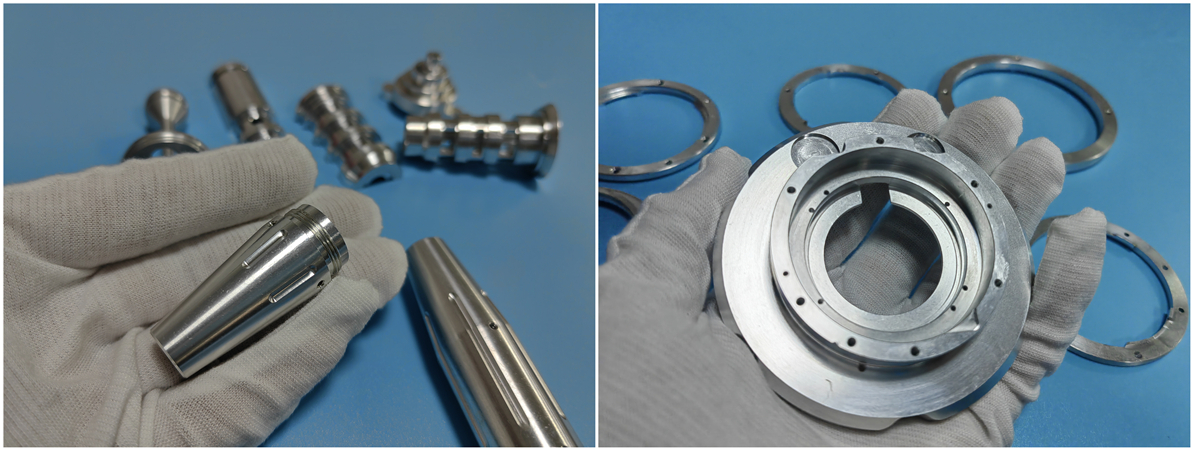

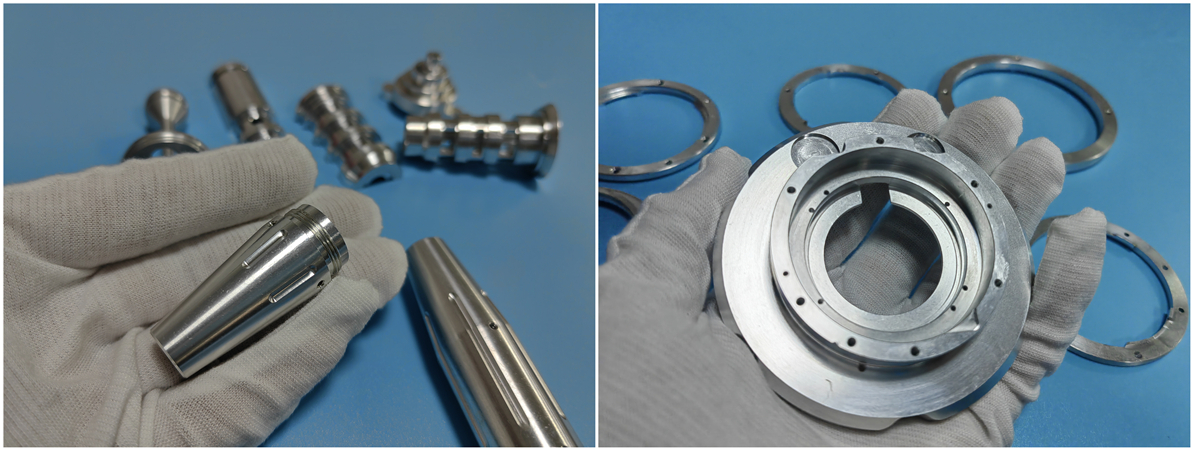

CNC turning precision parts are components produced by removing material from a rotating workpiece using cutting tools. Commonly, turning parts are cylindrical, conical or otherwise symmetrical around an axis. Turning parts can be found within the heart of countless assemblies all around us, from floor-standing mechanisms to compact pieces of high-precision machinery.

Key Characteristics of Turning Parts

While it takes plenty of skill and training to accurately manufacture turning parts to a high standard, certain characteristics set our products apart from the rest, namely:

Cylindrical Geometry Perhaps the most common variety of turning part, most parts are circular, including shafts, pins etc.

High Concentricity The higher the reach, the more essential concentricity is, especially where the parts rely upon rotation or interconnectivity.

Precision Surface Finish Enabling everything to move smoothly and resist friction in mechanical usage.

Complex Features Threading, grooving, edging, or steps in diameter and novel cut-out features.

Diversity of Material Range In terms of metal selection from aluminium through brass and stainless-steel, further back to specialist alloys.

Applications of Turning Parts:

Industry | Example Turning Parts |

Automotive | Shafts, bushings, custom fasteners |

Aerospace | Connectors, precision fittings, actuator components |

Medical | Surgical instruments, implantable devices |

Electronics | Brass pins, conductive connectors |

Industrial Machinery | Spacers, sleeves, shafts |

Any industry that encompasses products where mechanical precision, tight tolerances, and reliable performance are required will see that these turning parts are critical for optimum production.

What is a CNC Turning Center?

While every turner worth their digital weight will tell you how crucial the CNC lathe is for the success of each job, many aren’t aware of just how transformative turned part production really is. A CNC turning centre consists of several sub-components, including several others that are linked either in operation or logic function.

So, what makes CNC centres tick? The features of CNC turning centres include:

Automated Computer Numerical Control Highly configurable, the CNC mechanic can thus control how the apparatus works via software.

Rotational Aspect Where hundreds of worker flaws can be papered over manually, or intentionally disguised right from the start, simple rotation does most of the work for turning machines.

Multi-Process Capable A competent CNC lathe machine that is conversely superbly smart by nature, will go beyond control incutting and control through drilling-grooving-chamfering or whatever you call it and do it all in a single set-up.

High Repeatability Given how close we can allow the work with CNC machinery, this is where it differs from your more run-of-the-mill country custom turners. Tolerances below +/-0.002 mm are more than achievable.

Variety of material Depending on the machinist and materials available... or not!

Swiss Turning Capable The expert appendage from USA comes into play when you try and turn a long, slim part. It’s demanding enough as is, but with intricate turns, keystrokes and the like it gets vastly worse. However, alas, we are left with a solution.

Advantages of CNC Turning Centers:

Advantage | Benefit |

High Precision | Consistent tolerance and quality for complex parts |

Multi-Material | Aluminum, brass, stainless steel, and more |

Scalability | Ideal for prototypes to high-volume production |

Efficiency | Reduces setup time, tooling changes, and secondary operations |

Complex Geometry | Can create threads, grooves, stepped diameters, and more |

Our CNC Turning Capabilities

Falcon CNC Swiss provides a full range of CNC turning services with unmatched expertise:

Material | Capabilities | Applications |

Aluminum | CNC lathe turning, Swiss turning | Aerospace, automotive, electronics |

Brass | CNC lathe turning, custom parts | Precision fasteners, connectors |

Stainless Steel | CNC lathe turning, Swiss turning | Medical devices, industrial machinery |

Why Choose Falcon CNC Swiss for CNC Precision Turning Parts?

Swiss & CNC Turning Expertise: Perfect for high-precision, long, and slender components.

High-Volume Production: Maintain consistent quality for large orders.

Custom Design Support: We produce complex geometries tailored to your requirements.

Material Versatility: Extensive experience with aluminum, brass, and stainless steel.

EEAT Backed Quality: All parts are manufactured under strict quality controls and ISO standards.

Falcon CNC Precision Turning: Why We’re Better than the Rest of Them

As one of the best precision CNC turning parts suppliers in China, Falcon focus on precision CNC turning services and high volume Swiss machining.

Extreme Precision: Reach tolerances of concentricity up to ±0.002mm for parts with critical specifications.

Intelligent Tooling: Multiple step operations achieved in a single setup, reducing potential for errors and need for secondary operations down the line.

Smooth Surface Finish: Come to us for mirror-like finishes for functional and decorative purposes alike.

Batch Scalability: From prototyping, all the way through small orders to great big runs of components, all without sacrificing quality.

Targeted Engineering Guidance: Leverage our knowledge of design-for-manufacturing to produce your parts and slash costs at the same time.

Final Thoughts

Whatever your need – high precision cnc turned parts, CNC brass lathe turning machine parts, parts machined on our high-precision CNC Lathe Turning – Falcon CNC Swiss is the professional cnc lathe turning parts factory who has the technology, expertise and production capabilities to deliver with efficiency each and every time. See the gear as it’s actually being used at our CNC turning center and contact us now to see how we can help with your next project.