For producing parts with close tolerances and complex geometries, CNC turning is one of the most useful and precise manufacturing processes. Our CNC turning and Swiss turning options cover a range of rotating parts fabricated from aluminum, brass, and stainless steel that our customers use in applications that demand high precision and reliability.

What is CNC Turning?

CNC turning, or computer numerical control turning, is a process for shaping material into the desired geometries by holding the cutting tool in a stationary position while continuously rotating the workpiece around its axis. Compared to manual lathe turning, CNC provides high repeatability, consistent accuracy, and a high degree of complexity while removing as much human involvement as possible.

Key Features of CNC Turning:

Rotating WorkpieceMotion: The workpiece’s natural rotation rotates around its turning shaft while the cutting tool moves linearly.

High Precision: Part/systems can reach tolerances upwards of ±0.002 mm, making CNC turning useful for components found in the aerospace, medical, and automotive industries.

Complex Geometries: The CNC turning centers used today can fabricate complex thread, shaft, and stepped diameter geometries along with grooves and other surface features in one setup.

MaterialFlexibility: CNC Turning can cover aluminum, brass, stainless steel, and exotic alloys.

Efficiency and Scalability: Suitable for producing small-prototype runs as well as high-volume production decreasing both lead times and labor costs.

CNC Turning vs CNC Milling

Feature | CNC Turning | CNC Milling |

Workpiece Motion | Rotates | Stationary |

Tool Motion | Linear | Rotates & linear |

Ideal Parts | Cylindrical shapes | Complex 3D geometries |

Precision | High for concentric features | High for flat and contoured surfaces |

Common Materials | Aluminum, Brass, Stainless Steel | Aluminum, Brass, Steel, Plastics |

Understanding this difference helps engineers choose the optimal process for aluminum CNC turning parts, brass CNC turned components, or stainless steel CNC turning parts.

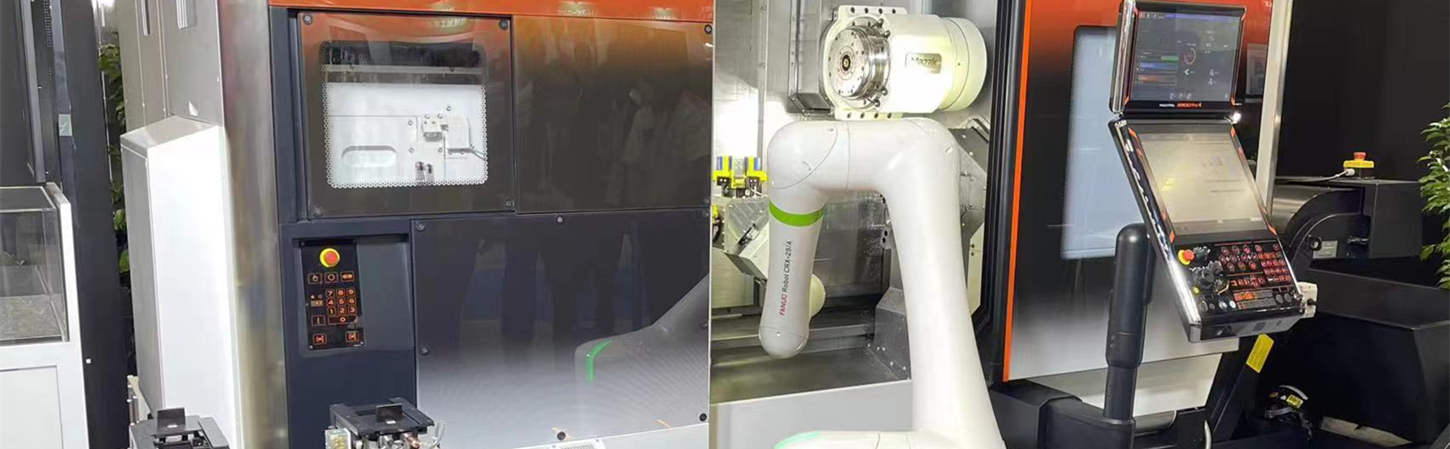

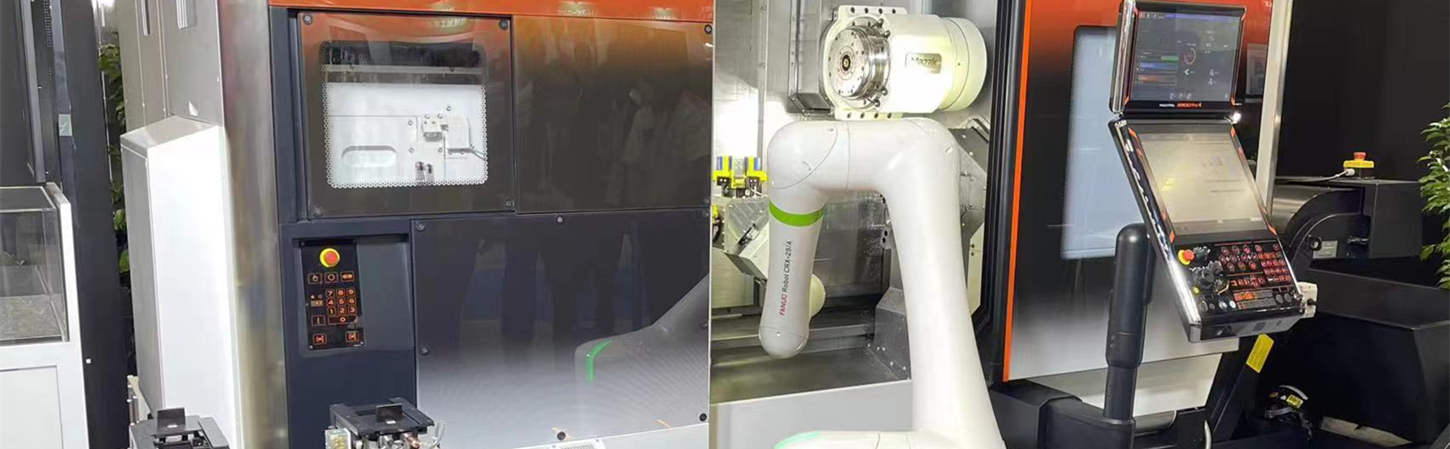

Our CNC Turning Expertise

Falcon CNC Swiss specializes in customized CNC turning parts, offering precision solutions for multiple materials:

Material | Capabilities | Typical Applications |

Aluminum | CNC turning, Swiss turning | Aerospace, automotive, electronics |

Brass | Swiss CNC lathe turning, custom parts | Precision fasteners, connectors, fittings |

Stainless Steel | CNC lathe, Swiss turning | Medical devices, industrial components |

Why Choose Falcon CNC Swiss?

Swiss Turning Knowledge- Great for long slender parts with tight concentric tolerances.

High Volume CNC Turning- Consistent quality across hundreds of thousands of parts coming off our lines.

Custom Part Configuration- Complex features on aluminum, brass and stainless.

Material Experience- Materials include aluminum alloys, brass alloys, stainless steels.

EEAT Backed Quality- Parts produced only with proven techniques and documented inspection processes, against ISO requirements.

Applications for CNC Turning Parts

Falcon CNC Swiss makes precision turned parts for these markets:

How Falcon CNC Turning Providers Get The Job Done Right

The combination of our Swiss turning experience with CNC turning gives Falcon CNC Swiss an edge over the typical provider of turning services.

Feature | Falcon CNC Swiss | Typical Competitor |

Concentricity (±) | 0.002 mm | 0.005–0.01 mm |

Material Range | Aluminum, Brass, Stainless Steel | Limited alloys |

Swiss Turning Capability | Full range | Rare / limited |

Batch Scalability | Small to high-volume | Limited mid-batch |

Engineering Support | Consultative DFM | Minimal |

Explore our CNC Turning manufacturing capabilities to learn more about how we can support your precision manufacturing projects.

Detailed Advantages:

Swiss Turning technology for small parts- We excel at long slender pins and shafts, but Swiss machining is also used for many fastening components for medical uses.

High volume production runs- Hydraulic component parts and others in medium to quarter million part order quantities are our specialty. Statistical process control assures that the parts stay in spec run to run.

Expertise with cutting materials- Parts composed of tool, aluminum, brass and stainless are in our past and present. We know how to optimize cutting parameters for good surface finish and accuracy among materials.

Diverse Tooling, and Multi-process Capability- Threading, grooving, complex profiles and no secondary ops, all in one setup.

Finish and Accuracy in Functional Parts- Mirror quality finishes for automatic hydraulic equipment, aerospace, medical.

Engineering Support and Customization- Using Design-for-manufacturing insight, we can help customers optimize parts for Swiss/CNC turning.

Conclusion

Whether aluminum CNC turning parts, customized brass CNC turned parts, stainless steel CNC turning parts, If you need the turn parts, Falcon is there. Quality is serious to us and we run the parts you need in CNC and Swiss turning machines. Talk with our team and let us show you how we can help you with good high quality reliable parts in demanding applications.

Our team combines advanced machining capabilities with deep industry experience, ensuring reliable, high-quality parts for demanding applications. Need a free quote for your precision components? Contact us today!