In today’s competitive manufacturing landscape, the ability to scale production efficiently is what separates the leaders of industry from the rest of the pack. For engineers, product managers and procurement agents, the true question is: How can you maintain unwavering precision, material integrity, and design fidelity going from prototypes to production runs into the thousands, and even hundreds of thousands of parts? The answer; advanced high volume CNC machining processes.

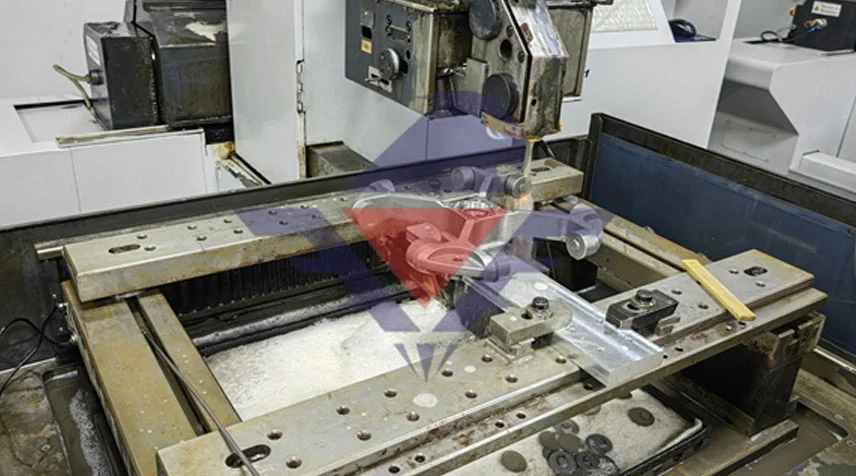

While basic 3-axis CNC mills and 2-axis lathes have a place, they are usually a bottleneck for any significant scale up of production. Going forward, the future of large scale manufacturing is closely tied to advanced integrated systems. When the combined advantage of 5-axis precision machining, and automated Swiss lathe production come together, they present a real path from design to mass production.

The Cornerstone of Engineering - Precision at Scale

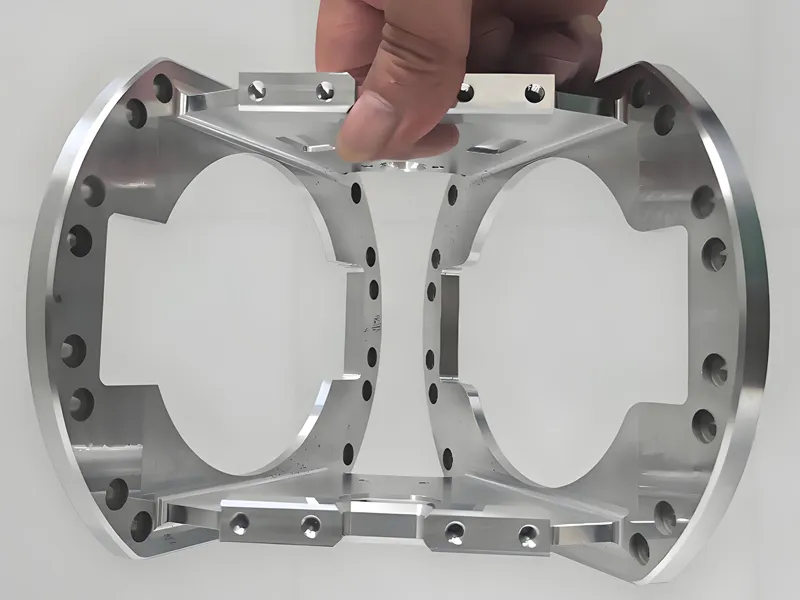

High volume CNC machining from an engineering perspective doesn’t mean running machines longer. It means designing a manufacturing process that guarantees repeatability and accuracy part after part.

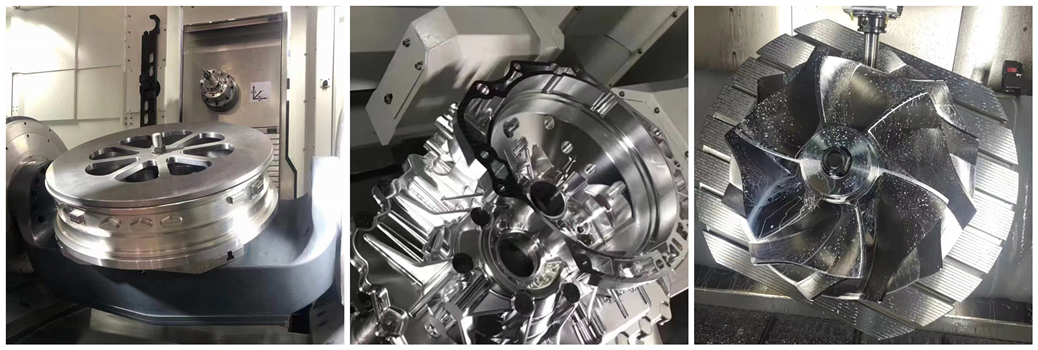

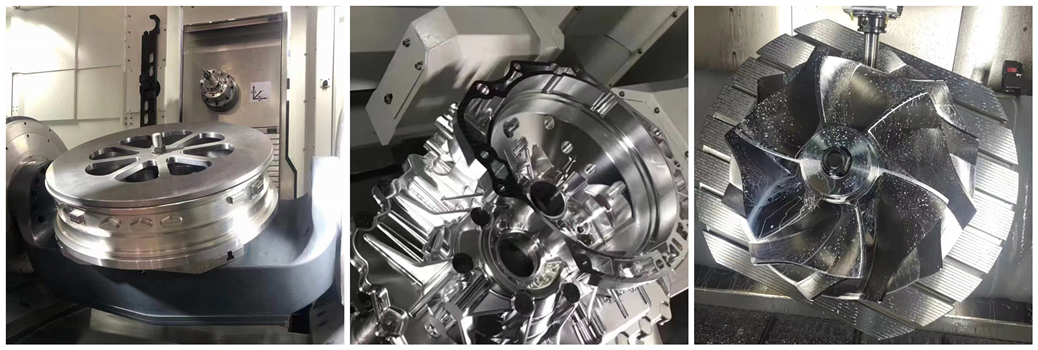

1. The Unmatched Capability of 5-Axis Machining:

A 5-axis CNC machine can orient a part on three linear axes (X, Y, Z) and two rotational axes (A and B) at the same time. This capability is essential for high volume precision machining of intricate parts.

Single-Setup Machining Control: The greatest benefit to high scale production is the speed of set up process. Compound parts that require multiple fixtures and operations on a 3-axis machine can typically be achieved in one setup in a 5-axis CNC machine eliminating cumulative error, therefore decreasing handling and ultimately provide better CNC machining consistency.

Best Position of Tooling: 5-axis CNC machines can continuously position the part at the most favorable angle in relationship to the cutting tool keeping the tool shorter and more rigid enabling higher feed rates and better surfaces, therefore machining complex features and deep undercuts that typically are not possible with 3-axis technology - all of which are relevant for the manufacturing of complex parts.

2. Swiss-Type, The Gold Standard for Efficiency for Rotational Parts:

Automated Swiss lathe production is incomparable for high volume, small, complex, cylindrical parts. Originally, they were designed for watch making, eliminating the “greatest” Swiss lathe strengths - precision.

Continuous, Unmanned Operation: Swiss lathes run with a guide bushing to support the bar stock exceedingly close to the cutting action. The supports the parts at precise tolerances, while performing intricate machining. When this is paired with a bar feeder and a part conveyor, they can run unmanned for hours. Automated Swiss lathe processes are in their design for massive quantities of turned parts.

Secondary Operation Integration: Contemporary Swiss lathes typically have live tooling (milting and drilling operation) and back working spindles. Which facilitates multipurpose operations - turning, milling, cross-drilling - all within one cycle, effectively creating a “done-in-one” CNC machining cell design appropriate for high volume CNC services.

The Business Case: Driving Down Costs and Time-to-Market

In addition to technical specifications, the business benefits of advanced high volume CNC machining displays visible benefits to the profit margin and operational responsiveness.

Cost Savings: While the upfront costs are higher for 5-axis CNC machining and Swiss lathe technology, the Total Cost of Ownership (TCO) in large volume manufacturing decreases substantially. Automated systems reduce labor, superior precision decreases scrap rates, and second operations can be reduced, resulting in a lower cost per processed part. From a business viability standpoint, high volume contract manufacturing can be a very economical option.

Time Savings: Single set-up machining and automation for material handling drastically reduces lead times. Businesses can react to demand faster, get products to market more quickly, and handle inventory management better due to on-demand manufacturing and scalable CNC solutions.

Supply Chain Simplicity: Selecting a manufacturer with high volume precision machining capability adds simplicity to your supply chain. Instead of juggling multiple sources for individual parts, use a single point of contact of high volume precision parts, with whom you can develop, manufacturer and deliver millions of precision parts. Reliability is the foundation of the durable parts manufacturing model for critical industries.

Market Applications: Precision and Volume

This manufacturing approach is not theoretical, it is the basis for innovations in some of most challenging industries.

Aerospace & Defense: Aerospace requires durable parts manufacturing from exotic materials, like titanium and Inconel. 5- Axis high volume machining is utilized to manufacture durable structural components, engine components, and landing gear assemblies, considering strength-to-weight ratios and trust/certifications.

Medical Device Manufacturing: The medical industry requires the ultimate in biocompatibility and CNC machining consistency. Bone screws, surgical instruments, and intricate orthopedic implants are all produced using automated Swiss lathe production and 5-axis machining with every part produced being compliant with stringent FDA and ISO compliance.

Vehicle Development: The move to electric vehicles (EV) and the development of advanced driver-assistance systems (ADAS) has led to a massive increase in demand for highly precise components for automotive applications. Everything from delicate sensor housings and connectors to lightweight structural components for EV’s are produced using high volume CNC services.

Selecting a Manufacturer

Choosing a vendor for your high volume CNC machining needs is strategic. You want a vendor that can demonstrate:

Machinery: A sufficient number of 5-axis CNC mills and multi- axis Swiss-type lathe machine tool capacity .

Quality: Established quality certifications like ISO 9001:2015 certification and AS9100D certification, along with extensive in-house metrology for first article inspection and statistical process control.

Materials: Experienced manufacturing a variety of material including, but not limited to, plastic, aluminum, stainless steels, and high performance alloys.

Past projects: Proven experience in delivering a successful high volume contract manufacturing project within your industry.

Conclusion: The Strategic Value of Precision Machining

In today's global economy, CNC machining at high volume isn't a simple commoditized service. It's an engineering process utilizing processes like 5-axis machining and automated Swiss lathes to achieve substantial improvement on cost, quality and scalability. By applying scalable CNC processes to your product’s fabrication, you’re able to minimize costs, decrease time-to-market, and even innovate in product design and functionality, including significant complexity.

Do you want to scale your manufacturing with confidence? Contact Falcon CNC Swiss today and let’s discuss how our high-volume precision machining services can be the launchpad of your next great product! We are happy to provide you details of our volume quote process and a proposal to show you why we are a leader is large-scaled manufacturing.