The robotics revolution is not some science fiction story anymore; it is an industrial and technological reality right now. From humanoid robots traversing complex environments to collaborative arms working in concert with humans to autonomous systems revolutionizing logistics, the need for complex robots is exploding. Underpinning this revolution is a critical discipline of manufacturing: the manufacture of custom robot parts for high-performance. The complexity and performance needs of these components cannot easily be produced by traditional manufacturing. Therefore, the industry is increasingly settling on the flexibility and precision of 5-axis CNC machining.

This blog will explore why 5-axis machining has taken the lead in the production of precise robotic parts, while looking at the engineering demands, the obligating business advantages, and the market forces driving this beauty.

The Engineering Demand: Why Custom Robot Parts Need 5-Axis

Robotics, by definition, is on the edge of mechanics, material science, and design. The parts needed are not simple clips, they are complicated, very integrated, and mission critical parts.

1. Complex Geometries All at Once:

The robot performance is a function of kinematics, weight, and stiffness. 5-axis CNC machining can produce complex, organic shapes, deep pocketing, and complex contours that cannot be machined in one hit on a 3-axis machine.

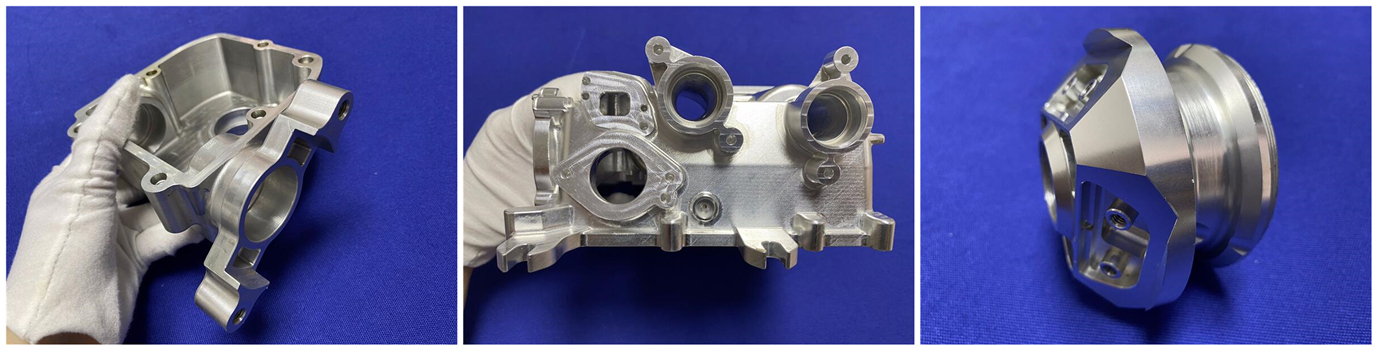

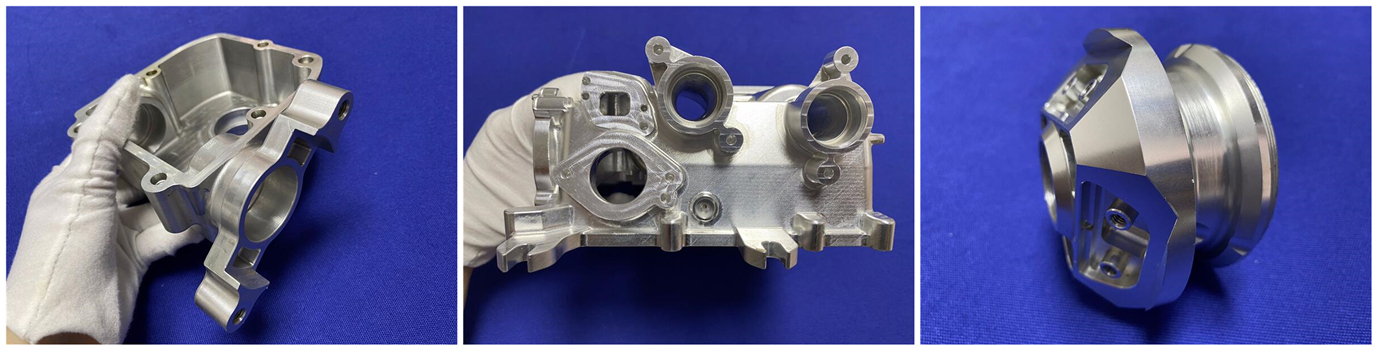

Anatomy of a Joint: Think about a humanoid robot hip or shoulder joint. That is not a simple hinge, that is a complex assembly, an engineering marvel that needs lightweight, very strong housings, that incorporate mounting points for actuators, cable pass through, and bearing seat surfaces in compound angles. With 5-axis machining, the entire hip housing can be produced as a single, solid part to guarantee precise alignment and no cumulative tolerances caused by a multi-part assembly. For complex robots, this is a requirement.

Topology Optimization: Modern design software can produce organically-shaped, lightweight parts where the parts are structurally optimized. These “generatively designed parts” are ideally suited for 5-axis CNC machining as the machine is able to accurately reproduce the part shapes and geometries from a solid (or a sheet of stainless steel) and leave you with lightweight robotic structures without losing strength.

2. Unbeatable Precision and Surface Finish:

The precise, smooth operation of a robot is a function of how accurate the parts are. Any backlash in a gear set or misalignment of the links to the arm could spell disaster or unusable operation.

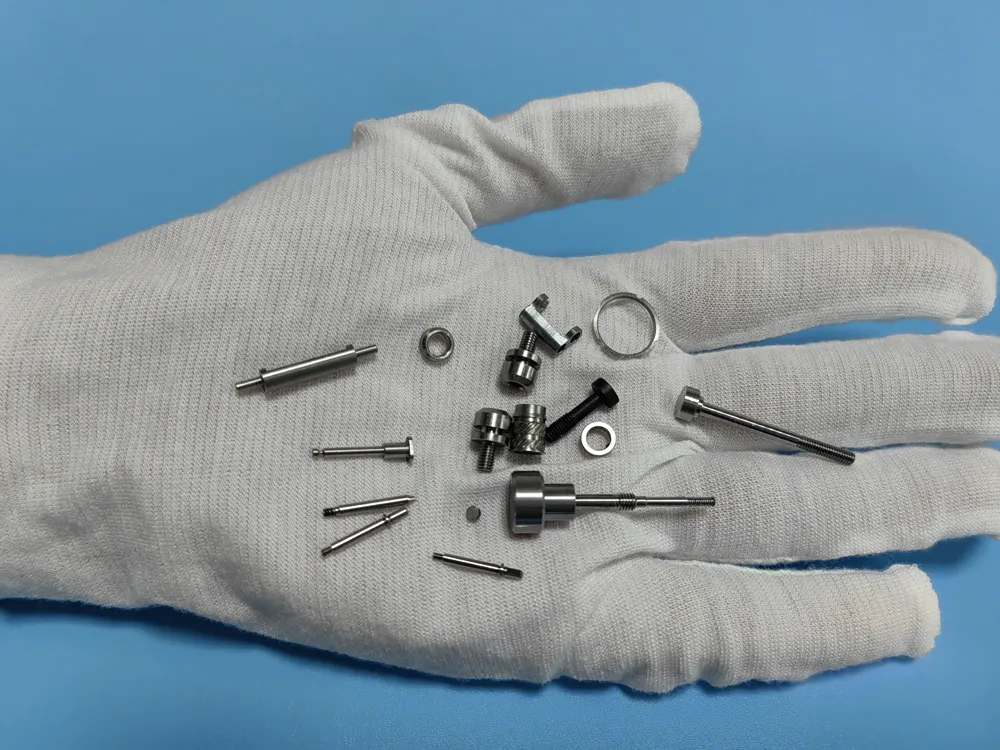

Dimensional Accuracy: The primary reason for the 5-axis machines are better accuracy is because they allow the cutting tool to take the most effective cutting angle to the work, which maintains proper perpendicularity and minimizes cutting tool deflection. This is very important to produce high-tolerance robot gears, end effector mounts, and actuator housings (where hair follicles count).

Ideal Surface Finishes: By allowing the cutter contact point to remain consistent and using shorter, rigid cutting tools, you get great surface finishes. It can make your custom end effector capable of managing delicate objects, reduce sliding surfaces, and component which minimize friction.

Material Flexibility for Challenging Environments:

Robots experience many different environments, making for a variety of materials. CNC machining for robotics needs to machine everything from light weight aluminum alloys to high-strength titanium and engineering plastics like PEEK.

Strength-to-weight ratio: Al 7075 and 6061 are common materials used in light weight robotic frames and structural links. For tougher applications, like aerospace robotics, or industrial arms under high loads, machining robots from titanium provides you with a lot of strength without adding a lot of weight.

Wear and heat resistance: Components for robots like gears, bearings, and joints often use tool steels or stainless steels, such as 17-4PH for wear resistance and corrosion stability, for long-life durable robotic components.

Column 2 of Business & Market Analysis: Investing in Advanced Manufacturing

5-axis cnc machining for your custom robotics is not only an engineering decision, but also a great part of your business strategy.

1. Reduced time to market

In this way, 5-axis cnc machining is significantly faster than other options, such as multi-step conventional. The "single-setup" ability that enables not only a single body of a complex part to be machined, thus greatly reducing lead time to production for robotics. Manufacturers can move faster with design, prototype and get to market before slower competitors. The fundamental principle for on-demand robotics manufacturing.

2. Cost-effective at all levels

A higher per-hour machine costs of 5-axis and having a lower total cost.

Less assembly labor: Instead of using multiple components to be manufactured, handled, and assembled, machining one unit obviously saves all the labor costs.

Less tooling: CNC machining is generally a low-cost investment process. Other processes, such as injection molding and casting with expensive and time-consuming molds have no up front tooling costs. CNC machining is the method of choice for low to mid-volume production of robotics, from prototyping to early market production runs.

Less scrap and rework: Highly precise manufacturing process yields lower parts rejections and less scrap. The net result is a decrease in tool and material costs that affect the bottom line.

3. Meeting Explosive Growth of the Market

Robotics market is growing at explosive rates globally and across all industries:

Industrial Automation: Custom end effectors and specialized jigs and fixtures for specific assembly tasks will never diminish.

Humanoid Robotics: The leading edge field requires us to build the most advanced, supervise robotic components and avoid using anything except light weight robotic frames and complicated, articulated joints that emulate human ergonomics.

Medical Robots & Cobots: The amount of safety, precision and reliability required is beyond any other currently promoted application. The demand should also place a limited restriction on the material machine; most use clean, long-life and lightweight robot components and equipment that are almost magnetic free. Such a great area for CNC machining with advanced robotics.

Falcon CNC Swiss is here for you as a solution and source of experience

Choosing a manufacturing partner is never a minor decision. Falcon CNC Swiss is not at all a supplier of your standard parts. We arrange it so you can use our expertise, and advanced manufacturing method allowing us to machine the durable robotic components that your innovation will rely on for its ruggedness.

Our capabilities are designed to support robotics industry requirements:

5-Axis Precision Machining – For exceptionally intricate structural frames and robotics assemblies.

Metrology – Making sure every component is machined to the precision tolerances needed to have a robot function flawlessly.

Material Science – Coaching you on the best material selection to suit strength, weight, and deployment environment.

Conclusion: Precision is the Cornerstone of Autonomy

The future of robotics is being built today, one precision part. The motions of actuators, sensors, and structures that allow them to perceive and interact with the environment are based off the manufacturing foundation that ties all together. 5-Axis CNC machining is not just a process for manufacturing a custom robot part, it is an enabling technology. It provides the design flexibility, material integrity and geometric precision needed to transform innovative robot designs into functioning, safe, and deployable commercial solutions.

Are you ready to build the future? Contact Falcon CNC Swiss today to discuss your project! Let our experience in 5-Axis CNC machining and custom robotics manufacturing help bring your cutting edge robot designs to completion. Ask for a full quote and find out how we can be your partner in innovation.