Fluid connectors are essential in hydraulic and other fluids systems where quality of fit contacts, sealing, and dimensions directly determine safe and efficient operation. Making these components is not simply creating fittings, it takes deep experience and expertise in machining and materials and how they interact.

At Falcon CNC Swiss, we manufacture fluid connector products with Swiss, CNC and other advanced machining techniques for tightly toleranced and critically functional components for high-speed industrial usage.

Fluid Connector Product Manufacturing: Understanding and Experience

From a design and engineering standpoint, hydraulic connectors must project well under conditions of vibration and thermal change. This requires engineering and robust manufacturing experience in tight toleranced geometries and shapes.

Our experience and background in machining high-precision metal parts put us in the best position for:

Knowing great deal how the form of threads influences on leak-tight result

Realizing the relation between ra of finishes and leakage risk

The role of concentricity in assembly reliability

What the behaviour is of materials under an applied pressure

Our production and hands-on shop floor knowledge comprise some of the manufacturing skills in the bags behind our connectors for fluid delivery systems.

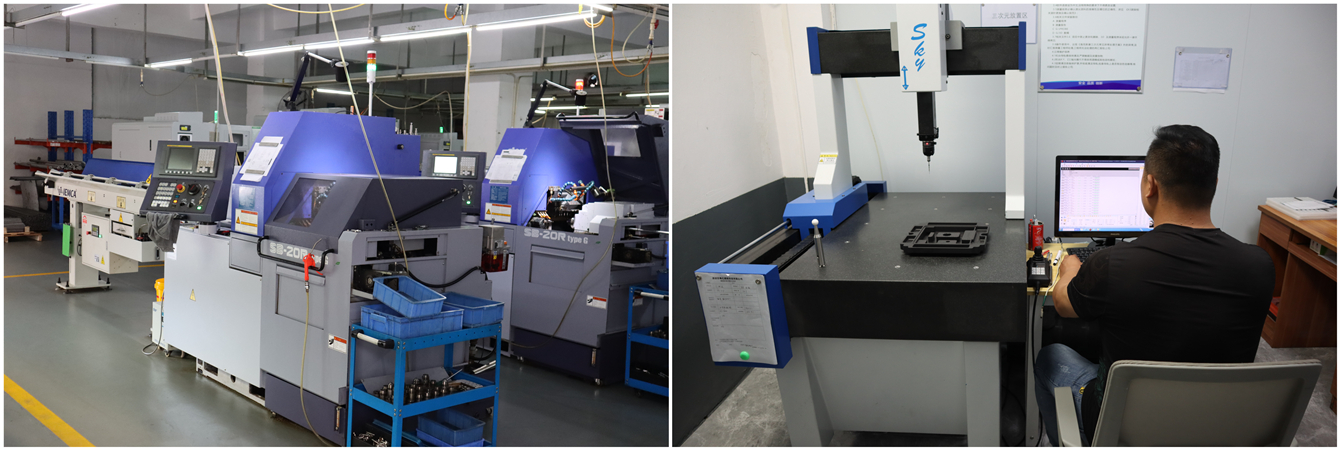

Swiss Machining Feeders: Very Small Diameters and Tight Controls

Providing feed for small, long, even slender and unevenly complicated fluid connector parts is dealt with effective means by Swiss-type machining procedures. Supporting the whole workpiece with sliding guidance close to the cutting zone brings exceptional dimensional stability, and Swiss parts are the rule for highprecision hydraulic fluid connectors and other threaded components.

Advantages of the Swisseffed technique for making fluid connector product offerings are:

Fluid connector quality in terms of wide use of controlling concentricity

Final accuracy of thread on Swiss-turned parts

Uniform surface finish on seal making areas

Close repeatability in volume runs.

CNC Machining for Connector Production

While Swiss machining is ideal for small simple components used in hydraulic connectors manufacturing, advanced CNC machining has capability for larger connector geometries as well as secondary operations. The combination of Swiss and CNC machining supports scalable production of fluid connect products of all sizes and complexities without compromising on quality.

Our CNC machining capabilities include:

Precision turning and milling

Complex port and adapter geometries

Secondary machining and finishing

Medium and large batch throughput

This hybrid mix of machining technologies is well suited to medium and large batch runs of fluid connectors from smaller hydraulic fittings to larger industrial connector components.

Hydraulic Connectors Materials

Fluid connector products are designed for service, so material selection is crucial to connection performance and service life. Our machining processes are optimized for some common connector materials:

| Material | Key Benefits | Typical Applications |

| Brass | Corrosion resistance, machinability | General fluid systems |

| Stainless Steel | Strength, chemical resistance | High-pressure hydraulics |

| Carbon Steel | Durability, cost efficiency | Heavy equipment |

| Aluminum | Lightweight, corrosion resistant | Mobile systems |

Understanding how each material machines—and behaves in real-world applications—is essential to producing reliable hydraulic fluid connectors.

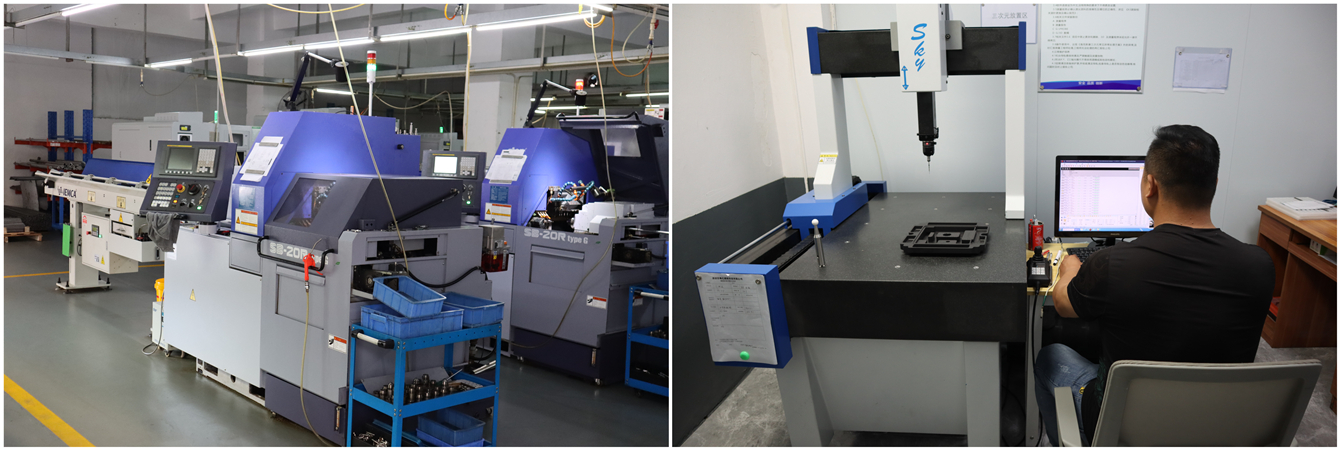

Quality Control and Production Reliability

Reliable fluid connector products depend heavily on discipline in every step of the machining and production process. We are focused on quality at several stages:

Tooling gauging and inspection

In process gauging of threading and other dimensions

Surface finish gauging on sealing faces

In process and final inspection

Each of these stages helps ensure that components meet functional requirements—not just dimensional ones.

Serving OEMs with High Volume Production

OEM customers for fluid connectors typically want suppliers who can provide a steady ramp in production without sacrificing precision. Our Swiss and CNC machining capabilities allow for:

Controlled output from batch orders

Consistent per-part quality from order to extended volume run

Controlled pricing with volume runs

Defined lead times for production programs

These are key, especially for manufacturers organizing for fluid connector products in hydraulic and industrial applications, and subsystem-level assemblies.

Precision Fluid Connector Products You Can Trust

From an EEAT perspective, reliable fluid connector manufacturing is built on real machining process capabilities and metrology. By combining Swiss machining precision with CNC bouts and design, seasons Falcon CNC Swiss builds connector products for function, performance, and medium to large runs of products consistently.