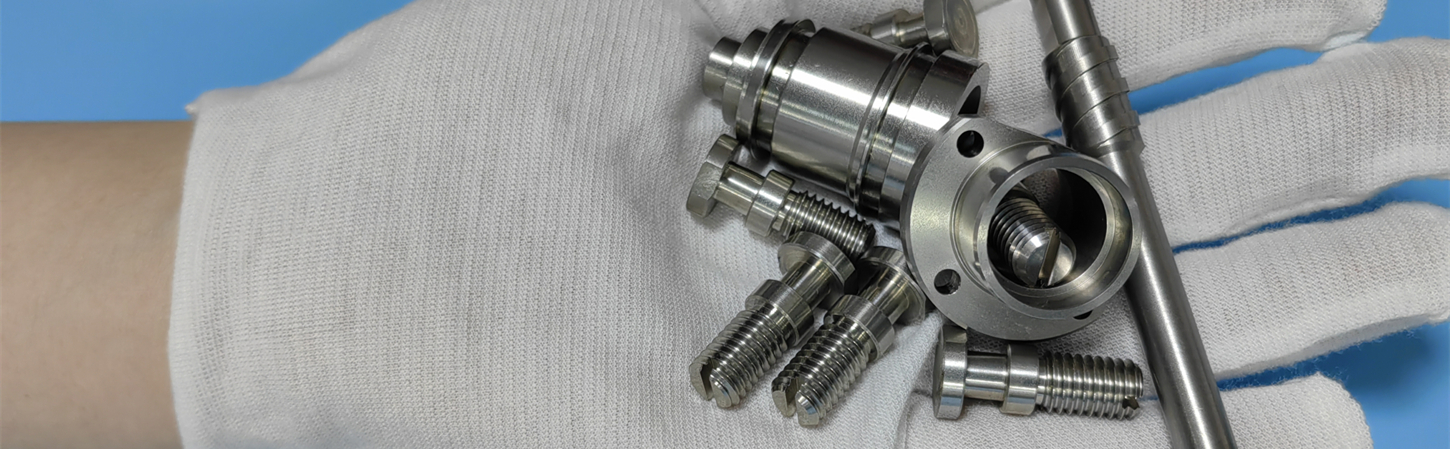

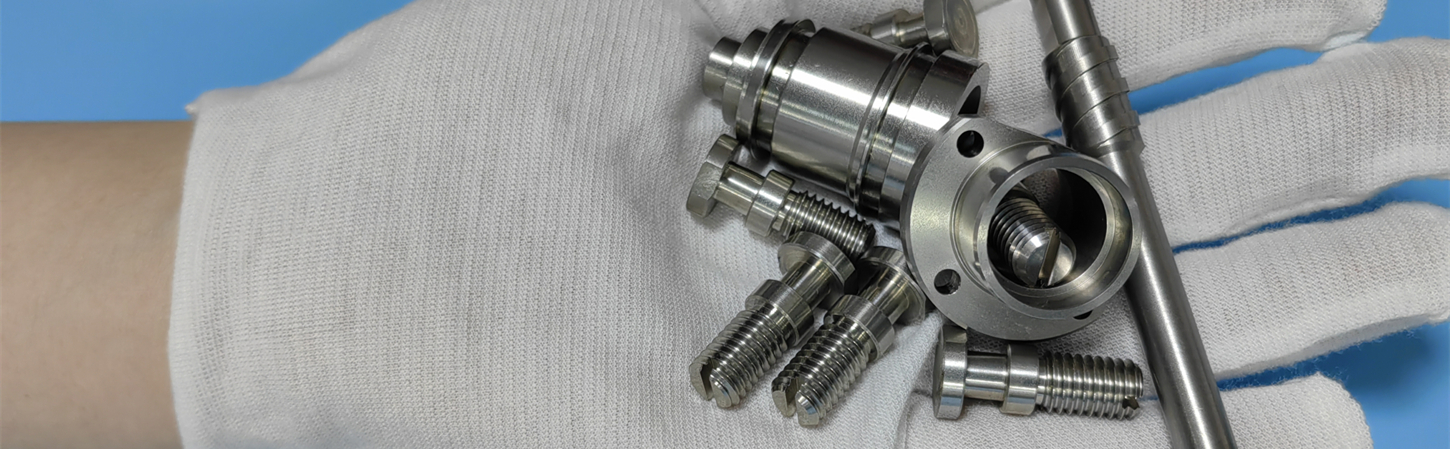

One of the most critical properties of materials used for fasteners and other mechanical components is dimensional stability of these features over time without warping, corroding or otherwise degrading. Stainless steel remains one of the most reliable materials for that application, as seen in everything from critical assembly (precision stainless steel machine screws) to custom stainless steel screw machine products.

In this article, we review stainless steel machine screws and screw machine parts, as well as some of the manufacturing capabilities to support high-volume production.

Why Stainless Steel for Machine Screws?

Stainless steel provides a desirable combination of mechanical strength, hardness and resistance to environmental degradation for demanding uses. Specific advantages of stainless steel machine screws include:

Excellent resistance to oxidation and corrosion

High strength and durability

Good dimensional stability at high and other extreme temperatures

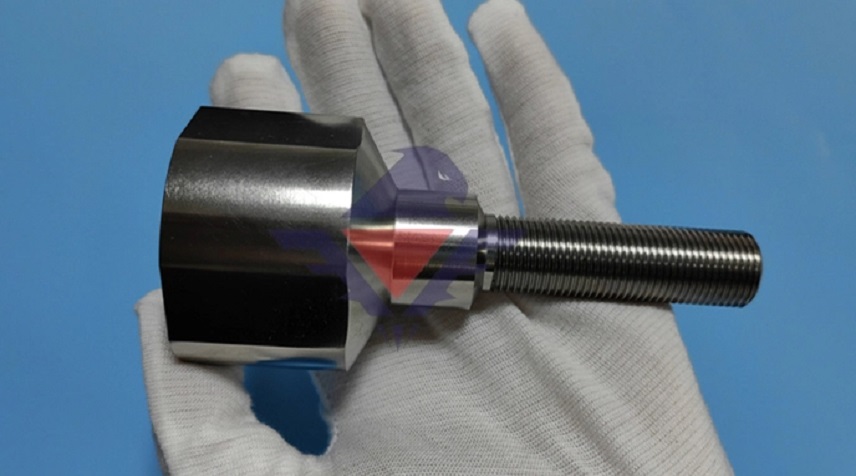

Ability to form precision threaded features

Long term durability and service life.

Auto parts, medical instruments, industrial equipment and electronics manufacturing are among the likely applications for stainless steel machine screws in demanding environments.

Precision Stainless Steel Machine Screws

Precision stainless steel machine screws are widely used in applications such as automotive sensors and controls, surgical instruments, industrial automation equipment and electronics.

Medical devices and surgical instruments

Automotive sensors and control systems

Industrial automation equipment

Electronics housings and structural assemblies

Manufacturing these components requires precision CNC screw machining that incorporates tight control of cutting tools, and in-process inspection to ensure consistent geometries and surface finish.

Stainless Steel Screw Machine Parts and Products

Beyond fasteners, many manufacturers require more complex stainless steel screw machine parts or stainless steel screw machine products such as:

Swiss-type CNC screw machining is the most common technique used for these special products, particularly smaller diameter components.

Custom Stainless Steel Screw Manufacturing

Successful custom stainless steel screw manufacturers have a deep understanding of both the properties of the material and the requirements of the application. For example, stainless steel—known for its hardness and edge-rolling characteristics—requires special treatment, such as:

Proper selection of tooling,

Control of cutting parameters, and

Control of the machining environment.

Custom stainless steel screw manufacturing is especially useful to allow a custom OEM fastener vendor to meet non-standard requirements for thread form, head styles, tolerances, surface finish, etc.

High-Volume Stainless Steel Machine Screws: What Defines Capability

Producers of high volume stainless steel machine screws “get it done” with more than correct machine count. They know that stability and production activity are key, and in the large, stable environment of stainless steel machine screws manufacturers, exist capabilities for production and prototyping without issue.

| Manufacturing Capability | Benefit to Customers |

| Swiss CNC Screw Machines | High precision for small, complex parts |

| Automated Bar Feeding | Continuous production for large batches |

| In-Process Inspection | Consistent quality across long runs |

| Process Optimization | Reduced cycle time and unit cost |

| Scalable Production Lines | Reliable delivery for repeat orders |

Stainless Steel Machine Screws Suppliers: More Than Production

For supply chain, stainless steel machine screws suppliers should provide a complete package of material certification and traceability, documentation of consistent quality, engineering support for design optimization, and flexibility with batch sizes as well as volumes. Controlling lead time and product consistency is much more achievable working with a stainless steel screw machine parts supplier that understands each element of the screw machine production process—operations, inspection and secondary operations.

Material traceability and certification

Consistent quality documentation

Engineering support for design optimization

Flexible batch sizes with scalable volume

Working with a stainless steel screw machine parts supplier that integrates machining, inspection, and secondary operations ensures better control over lead time and product consistency.

Industries Served by Stainless Steel Screw Machine Parts

Stainless steel screw machine parts are widely used across multiple industries, including:

Medical and healthcare equipment

Automotive and transportation

Industrial machinery

Electronics and electrical systems

Energy and fluid control

Each industry places unique demands on tolerance, surface finish, and reliability—making precision screw machining a key factor in performance.

Conclusion

From precision stainless steel machine screws to complex stainless steel screw machine parts, high-quality screw machining is essential for meeting modern manufacturing demands. By partnering with experienced stainless steel machine screw manufacturers and suppliers capable of high-volume production, OEMs gain consistency, reliability, and long-term value across their component supply chain.