Bushings play a critical role in modern mechanical systems by reducing friction, absorbing vibration, and ensuring precise alignment between moving components. From automotive suspension systems to industrial machinery and fluid handling assemblies, the demand for custom brass bushings continues to grow as engineers seek higher reliability, tighter tolerances, and longer service life.

As experienced custom bushing manufacturers, precision machining suppliers are now offering highly specialized solutions, including custom suspension bushings, custom control arm bushings, and a wide range of brass and bronze bearing bushes designed for demanding operating environments.

Why Brass Bushings Are Widely Used

Brass and bronze alloys are among the most popular materials for bushings due to their excellent combination of properties:

Good wear resistance under moderate loads

Natural lubricity for smoother motion

High corrosion resistance

Excellent machinability for tight tolerances

These advantages make brass sleeve bushings and brass bearing bushes ideal for applications such as automotive assemblies, pumps, valves, agricultural equipment, and industrial automation systems.

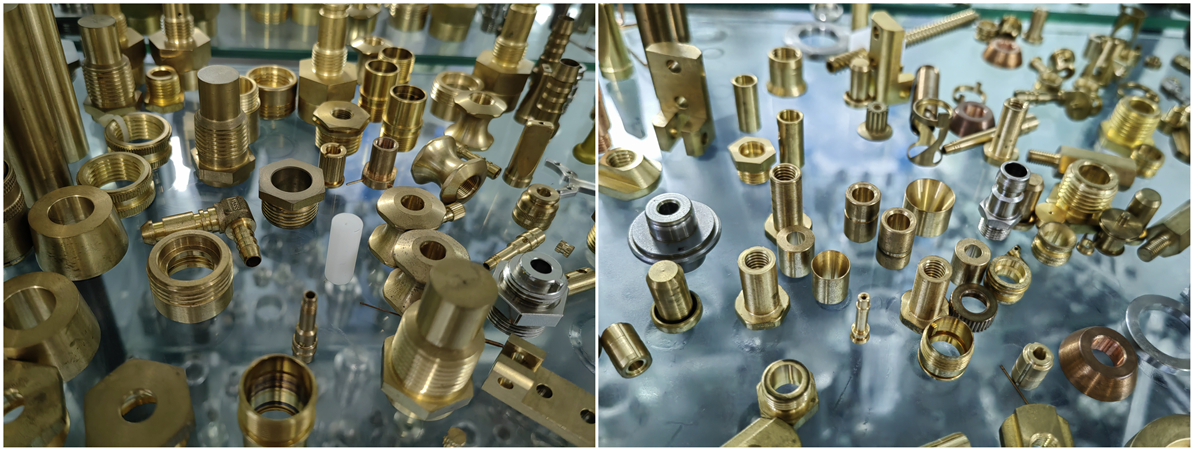

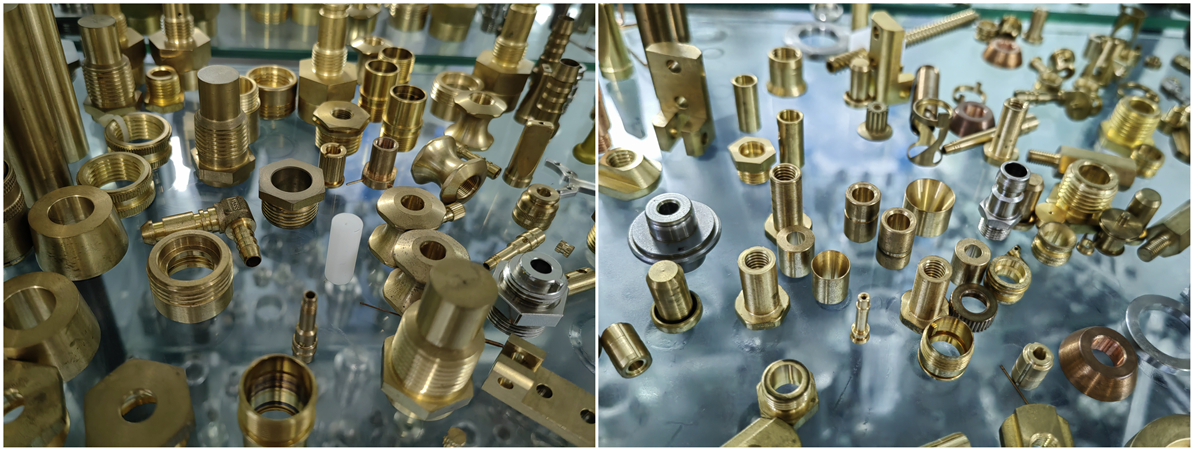

Types of Custom Brass Bushings

Modern manufacturers support a wide variety of custom configurations to meet specific design and performance requirements.

Simple cylindrical designs used for shafts and rotating components. Brass sleeve bushings are commonly used in motors, gearboxes, and linear motion assemblies.

Also known as flanged brass bushings or flanged brass bushing, these designs include an integrated flange to prevent axial movement and improve load distribution. They are widely used in housings and structural assemblies.

Brass bushings threaded internally or externally are often used as adapters, wear inserts, or reinforcing components in softer materials.

Designed to connect or reduce pipe diameters, brass pipe bushings are commonly found in plumbing systems, fluid control equipment, and industrial piping assemblies.

In higher-load or high-temperature applications, brass bronze bushing solutions (such as phosphor bronze) provide improved strength and wear resistance.

Custom Suspension & Control Arm Bushings

In the automotive sector, custom suspension bushings and custom control arm bushings are critical for vehicle stability, vibration damping, and ride comfort. Precision-machined brass and bronze bushings offer consistent dimensions and reliable performance under cyclic loads.

Compared with molded alternatives, CNC-machined bushings provide:

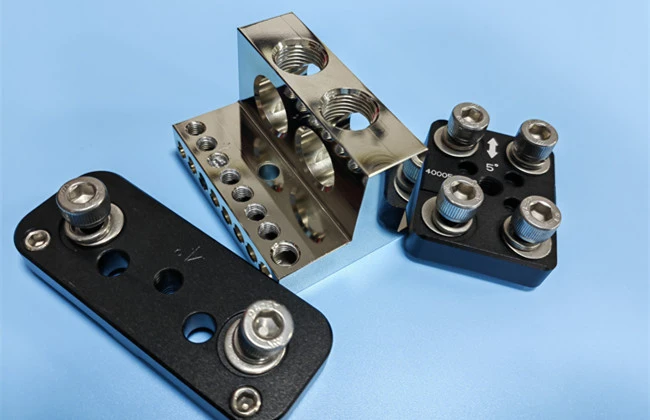

Precision Manufacturing with Swiss Machining

Producing high-quality bushings requires tight control over tolerances, surface finish, and concentricity. Advanced Swiss machining services enable manufacturers to produce complex bushing geometries with micron-level precision and excellent consistency.

At Falcon CNC Swiss, Swiss-type lathes are used to manufacture precision bushings with:

Learn more about our advanced capabilities through our

Swiss Machining Services: https://www.falconcncswiss.com/swiss-machining-services/

Inserts and Bushings for Industrial Applications

Custom bushings find broad use outside the automotive industry as wear-resistant inserts. Capabilities offered by precision brass bush manufacturers include customized inserts and bushings friendly to assembly designs which dictate load, speed and environmental specifications.

Falcon CNC Swiss offers CNC machined inserts and bushings for:

Explore our full range of precision inserts and bushings here: https://www.falconcncswiss.com/inserts-and-bushings/

Explore our full range of precision inserts and bushings:

Choosing the Right Brass Bushing Supplier

When choosing brass bushings suppliers, engineers and procurement teams should consider supplier more than price alone. Among the important concerns are:

Material traceability and alloy selection

Machining precision

Inspection processes and control of tolerances

Experience with custom, low to medium volume production runs

A capable partner with in-house CNC and Swiss machining experts can help optimize bushing designs, improving reliability and lowering total cost of production.

Conclusion

Using superior Swiss machining technology to achieve a wide variety of lengthy, precise runs of part precision machined from brass and bronze, manufacturers are assured of high performance in such parts as brass bushing sleeve and flanged brass bushing models. Custom suspension bushings and custom control arm bushings, along with many industrial applications, all start with a phone call to experienced custom bushing manufacturers.