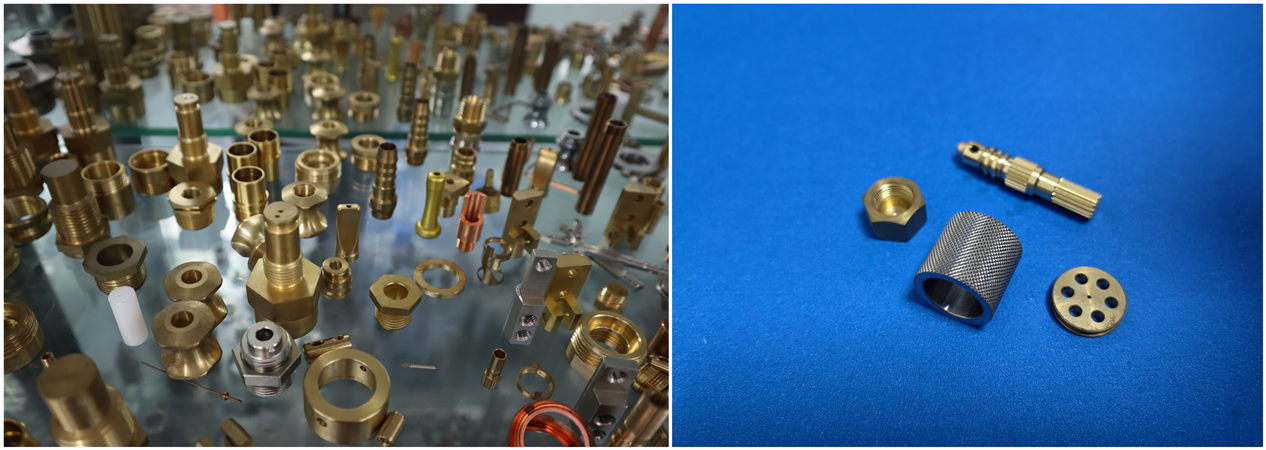

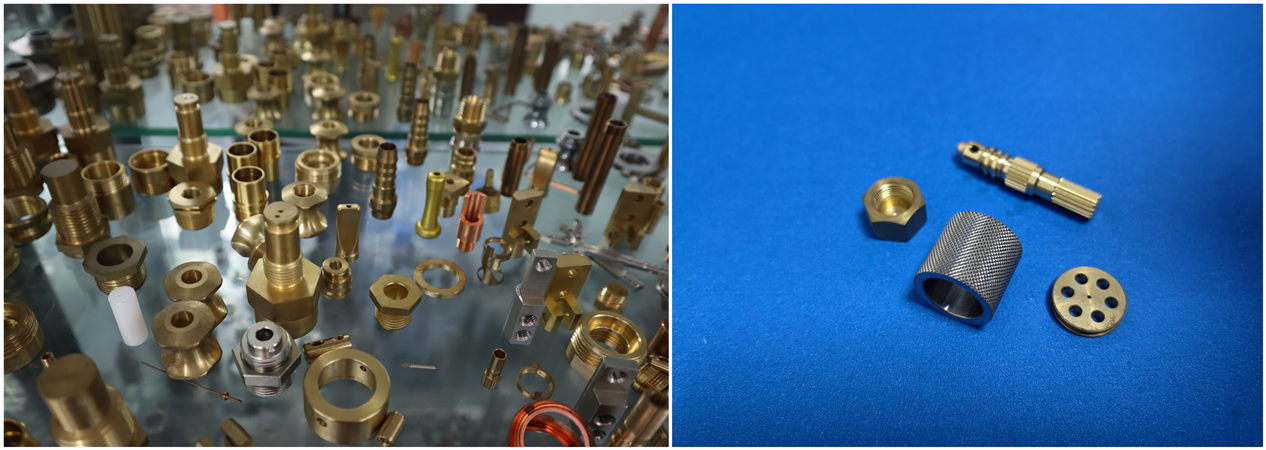

As the demand for resilient and precise fastening solutions grows in various industrial applications, brass inserts suppliers and makers are key to providing rugged threaded components for metal and engineered assemblies. Brass threaded inserts are often a material of choice because of their high machinability, corrosion resistance, and robust retention characteristics.

As an experienced brass insert manufacturer, Falcon CNC Swiss specializes in custom-designed solutions for a diverse range of knurled and threaded insert applications and provides service to OEMs and industrial buyers globally.

What Are Brass Threaded Inserts for Metal Applications?

Brass threaded inserts for metal are precision-machined components that create robust, wear-resistant internal threads in metal parts. Compared to tapping threads directly into softer materials, brass inserts greatly improve load-bearing capacity, service life, and assembly confidence. They are typically introduced via press-fit, heat insertion or threaded installation methods, depending on the application and base material.

Brass Insert Manufacturer with Swiss Machining Expertise

Because they are not mass-produced “fasteners,” high-performance inserts require very tight tolerances and consistent geometry. As a specialized brass insert manufacturer, Falcon CNC Swiss can produce inserts with:

Excellent concentricity and surface finish

Precision knurling patterns for better pull-out resistance

Tight thread tolerances for repeated assembly

Our high-precision Swiss machining service allows stable production of complex small brass inserts at volumes while holding micron-level tolerances.

Learn more about our capabilities here: Swiss machining services

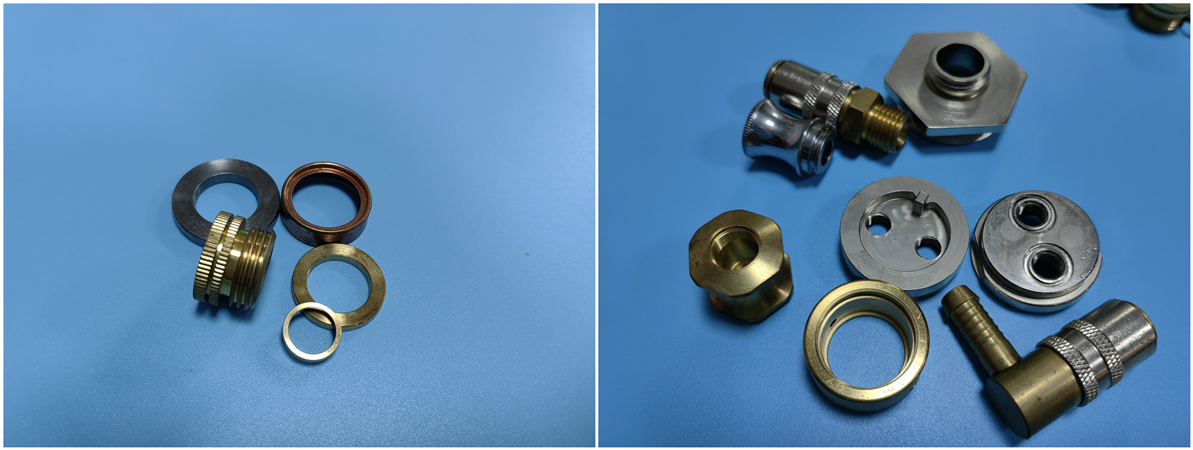

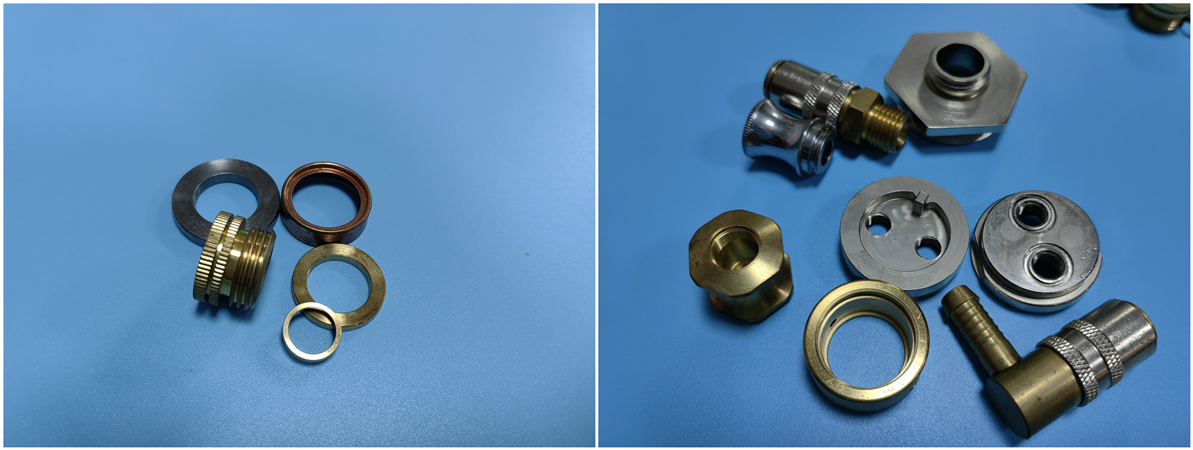

Knurled Brass Inserts and Brass Knurling Insert Designs

Knurled brass inserts feature external knurling that increases the mechanical locking effect of the insert in host material. These features help prevent relative rotation and axial movement under load. Typical brass knurling insert designs include:Straight knurlDiamond knurlHelical knurlThe specific knurl geometry selected relates directly to the installation method and hardness of the insert material. Precision Swiss machining makes it possible to hold bleeds on depth and knurl to consistent profiles critical to a high-strength assembly.

Brass Knurled Threaded Inserts for Industrial Use

Brass knurled threaded inserts combine internally-threaded insert features with outside knurling for both secure fastening and high pull-out strength. These inserts find application in automotive components, electrical housings, industrial enclosures and instruments, and medical parts. For buyers of these assemblies from brass insert nut manufacturers, important value considerations of small dimensional consistency and threaded features tie in successively into the downstream assembly process.

Custom Brass Insert Nut Providers: Meeting Unique Specifications

While standard insert nuts can fulfill many basic requirements, certain industrial uses necessitate the custom tailoring of dimensions, threads, or material grades. At Falcon CNC Swiss, we are among the most experienced of the brass insert nut manufacturers, supporting:

Engineering assistance to perfect inserts for automated installation and use longevity

Check out our full range of brass threaded inserts and custom insert services.

Picking a Good Supplier of Brass Inserts: Key Considerations

When selecting from among brass inserts suppliers, consider more than just price. Ask about:

The CNC Swiss machining capability of the shop

Quality control processes and traceability

Customization capability and prototyping support

Supply stability for long-term use

With a CNC Swiss-type shop floor and demanding inspection criteria, Falcon CNC Swiss has what it takes to deliver the dimensional consistency you need for prototype runs and into production as well.

Summary

From our knurled brass inserts to our brass threaded inserts for metal, precision manufacturing is what gives a part its performance. When you work with a veteran of brass insert nut manufacturers, you know that the component your piece needs is being built to exact specifications.

Heard enough about nuts to need a standard insert or fully-custom brass? Meet Falcon CNC Swiss for scalable, beautiful, accurate manufacturing!