Demand for high-accuracy fasteners is steadily growing in the automotive, electronics, medical devices, and industrial equipment markets. At the heart of this demand are CNC Swiss screw machine parts, produced through advanced CNC Swiss automatic machining processes that offer consistency, precision, and efficiency at high volume.

This article explains how Swiss screw machining supports fastener production today, how to define precision screw products, and how experienced fastener products manufacturers meet tight tolerances and high volumes.

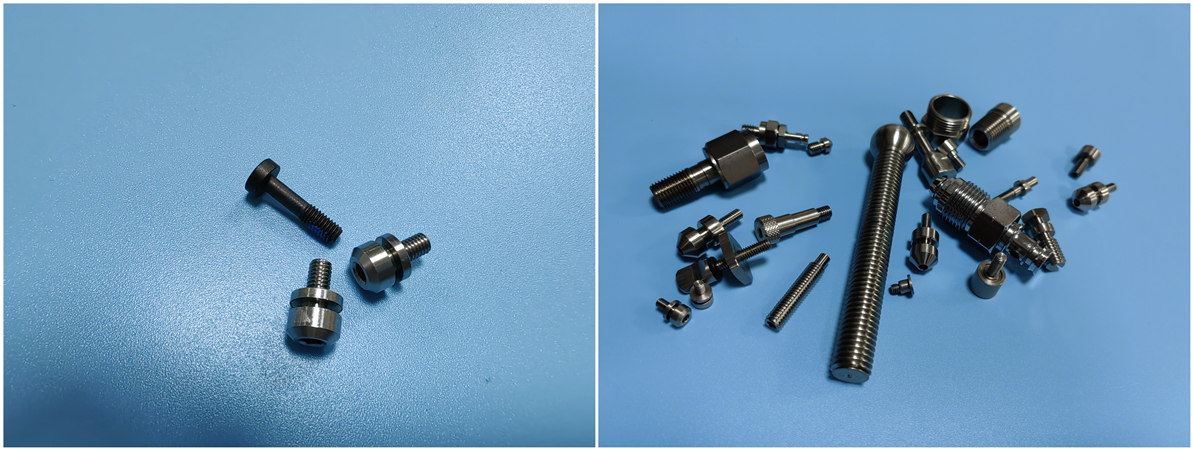

What Are CNC Swiss Screw Machine Parts?

CNC Swiss screw machine parts are precision components, produced on Swiss-type automatic lathes. Swiss machining differs from conventional CNC turning in that support for the workpiece takes place close to the cutting area. This allows for outstanding stability, especially for small-diameter and high-length-to-diameter parts.

Swiss machining finds usage in producing:

Precision screws and threaded components

Custom fasteners and miniature shafts

High-volume fastening products with tight tolerances

Companies with a strong reliance on consistent quality frequently turn to Swiss machining for repeatable, high-precision fastener components.

CNC Swiss Automatic Machining Explained

CNC Swiss automatic machining shares bar-fed automation with multi-axis control, allowing continuous manufacture of screw parts, screw, and fastener parts. These machines inhabit a landscape in which precision and efficiency are equally important.

Benefits include:

Dimensional accuracy for finished parts

Stable machining for longer, slender parts

Short cycle for large volumes

Integrated secondary operations such as drilling, additional, threading, and slotting.

With these advantages, Swiss machining becomes an attractive solution for precision screw products manufacturers and providers of complex fastening components.

Learn more about Swiss machining services tailored to high-precision screw and fastener production.

Precision Screw Products in Modern Manufacturing

Precision screw products see heavy usage in assemblies, where the use of reliable, repeatable fastening performance as a design feature is paramount. These products find application in:

Automotive and transportation

Industrial machinery

Medical and electronic assembly

Aerospace and high-performance products

Precision screw products inc and screw products inc are examples of companies that depend on Swiss-type to maintain quality standards and controlled efficiencies. To meet their expectations, fastener products manufacturers focus on process control and material selection and repeatable CNC machining.

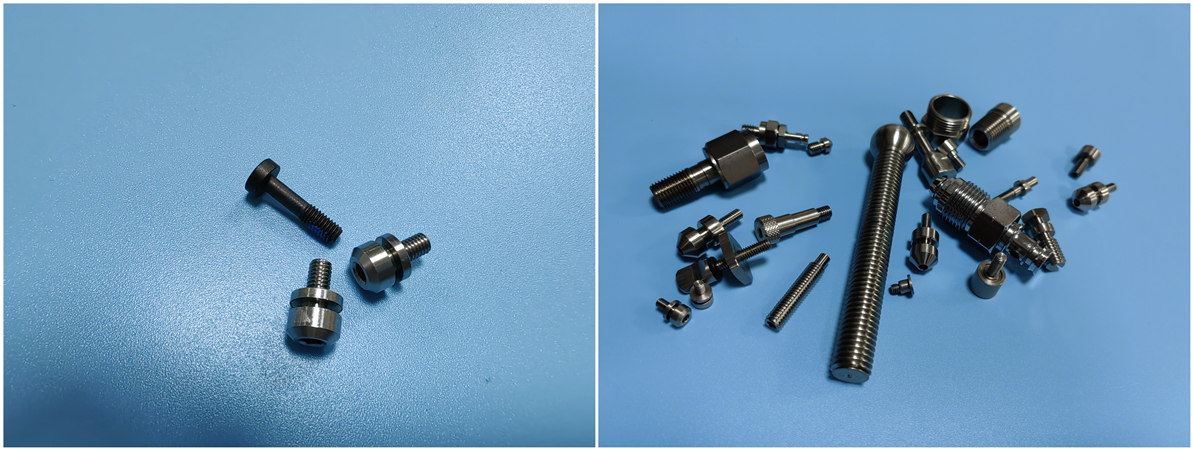

Fastener Production and Manufacturing Capabilities

Today’s fastener products manufacturers cannot simply begin their offerings with finished threads. Rather, they now must be able to achieve:

Tight tolerances and consistent thread profile

Multiple materials, from stainless steel, to alloy steel, brass, and aluminum

Stable, large-volume runs

Secondary finishing and inspection operations

Fastening products that meet both cosmetic and functional requirements are efficiently produced by voluminous fasteners manufacturers with CNC Swiss machining processes. For other fasteners, relating to bolts, nuts, and threaded fasteners precision machining remains vital for strength and fit, and long-term reliability. Follow through for applications in producing custom bolt and nut manufacturing.

How Fasteners Are Kept Precise

In most of the more complicated fasteners, it’s not just enough to bolt up two components using a simple threaded pin. The assembly fasteners inc and other manufacturers supply, are called on to do their job whatever they’re exposed to be it vibration, load, even environment.

Getting the precision just right means knowing how to handle:

The geometry and finish of threads

How to produce each part of a consistent size/grading

Material integrity and resistance to corrosion

Swiss screw machining allows the manufacturers to control these things with excellent accuracy and contributes greatly to the manufacture of quality precision fasteners inc in complex assemblies.

Why Swiss Machining Works for Fastening Products

Swiss machining works especially well for fastening products. Compared with habitual turning, Swiss machines means:

More support for slender fastener components

More reliable repetition for long term production runs

More pleasing surface aesthetics and less scrap

Many fastener products manufacturers are confident that Swiss machining will work to deliver precision screw and fastener products in automatic cycles.

Choosing Your Fastener Manufacturer

When you make your choice of a supplier of CNC Swiss screw machine parts look for:Swiss Machining

A manufacturer skilled also and showing expertise in CNC Swiss automatic machining.

Materials

Especially, a firm working the metals most frequently used to produce the parts you need.

Quality control

Things like inspection, traceability, and stability of process.

Scalability in production

That is, a firm capable of producing each part equally well in small prototype batches and for telecommunication orders.

Trustworthy Swiss machining services and custom bolt and nut manufacturing, and you’re set up to find secure and trustworthy fasteners for quality uses.

In Conclusio

From precision screw products through to more complicated fastening assemblies, CNC Swiss screw machine parts play a vital part today. With CNC Swiss automatic machining, manufacturers enjoy the preferred accuracy, consistency and efficiency to produce reliable fasteners.

Turning to the Swiss machining experts for bespoke Swiss screw screw products and custom bolt and nut manufacturing keeps several industries secure.