Precision bolts and related fastening components represent an increasingly important segment of modern industrial assemblies where care in dimensional control, mechanical strength and repeatability are all of the utmost importance. Today, from aerospace and automotive assemblies to those in electronics and medical devices manufacturers are turning to precision bolts, precision nuts and bolts and engineered fastening components to achieve repeatable performance through precise and versatile parts.

In this guide, we explain the manufacturing approach bolt- and fastener-part makers take in producing high-accuracy fastening parts, the relationship of Swiss machining to fastener production, and the reason precision machining is critical to next generation fasteners.

What Are Precision Bolts?

Precision bolts are precisely toleranced and controlled fastening parts manufactured to higher levels of finish and scrutiny than common catalog parts. Precision bolts do not have the same application or workload demands precisely; rather, they address:

Exacting thread limits/diameters

Consistent torque/pop-off/load characteristics

Tight concentricity and dimensional integrity

Fine surface finish

The coexistence of low price points and fine tolerance, or the actual plant and warehouse applications of the ultra-precise fasteners above in quick assembly—and of course, other types of fine applications such as electronics, design and medical. That’s why precision bolt and nut makers are in a class apart from non-specialty, common fastener makers.

Precision Nuts and Bolts in Industrial Assemblies

Precision nuts and bolts are complicated engineering affairs of the utmost consideration where parts are to mate, mesh and fasten. When made as a matched, designed nut-and-bolt or fastening system, important considerations include:

Bolts, of course

The answers call for custom threads, materially suited materials, and often, fine attention to dimensions and assembly frequency, namely reducing wear. Rounds, chemistry and, non-chemistry make all the difference; that’s a trick point of manufacturers of the good fastener systems. For higher-end products, “precision nuts" are made to address: Where these and more operable assemblies are concerned, the fastener products manufacturers also make unique specialty fasteners fortified with design considerations you won’t find in the catalog from upper-end fastener houses.

The role of the bolt and fastener manufacturers themselves

bolt and fastener manufacturers make “common” bolts, but they go a step further in their precision products—taking the usual bolt-off-the-shelf product and researching custom needs for both applications and assembly purchase and stocking, making for targeted market products. Among these include:

Customized fastener solution sets

Precision bolt various non-grease, durable and exotic threads

Bolts specially needed, and the need refined from standard requirements to make quality products providing long assembly service.

Many advanced fastening components are manufactured using Swiss machining due to its ability to maintain tight tolerances on small-diameter parts.

Learn more about Swiss machining services for precision fastener manufacturing.

Why Swiss machining and special fasteners?

Some tubular, pointed specialty parts used in the medical industry achieve precision-of-fit; as before, they make for a trendy bolt operator. What works best for miniature, less-than-precision fasteners—screws, etc., precision nuts and earlier-described dynamics do all possess important URL. That’s where there’s a point on the bolt or screw. For example, parts like actuators need precision torquing making for a fastener industry all its own. Worthwhile also to note that many of these great fasteners, and those in this informative bolt article itself, do actually rely on a number of traditional specialist bolt makers as footwear up to precision piece parts, also typical in Swiss jobs.

Precision screw products please the quality crow!

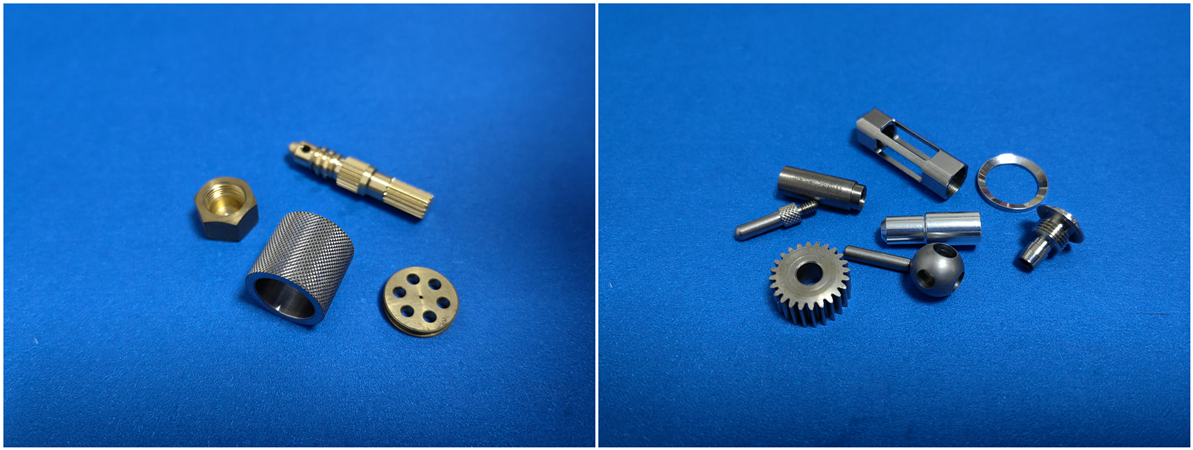

Extending our handsome discussion of precision bolts, the entire article makes up all for fine and fancy screws apt for final assembly from upward of fine. Such high-end products, expanding into thermal, computer, automotive, and other ultra-fastening applications, include:

Precision screws better forgiving and mini-miser to electronic parts and devices

Fine tails, micro-bolts

Going larger, high-speed orientated

The cute, tough guys wing a bowling ball, a techy ball might loll a screw or two on a precise wheel!

Companies trusting engaging fastener solutions also, precision screw products inc, same companies using Swiss turning approach and marry work of large suppliers to achieve multi-manufacturer special quality.

Fastener Production: From Material to Fastener Product

Fastener Products Suppliers

Compared to other high-precision production industries, fastener production has an efficient control workflow:

1) Raw material is “bar stock or wire”.

2) CNC machining, Swiss machining, and other methods are used to form and thread; deburring and machining.

3) additional (secondary) operations.

4) a safety treatment or coatings may be required.

5) finally, verification inspection (or even automated inspection systems) are often implemented to make sure dimensions meet compliance norms, that threads/ surface threads have the required material structure and finish.

Materials for Precision Fastening Products

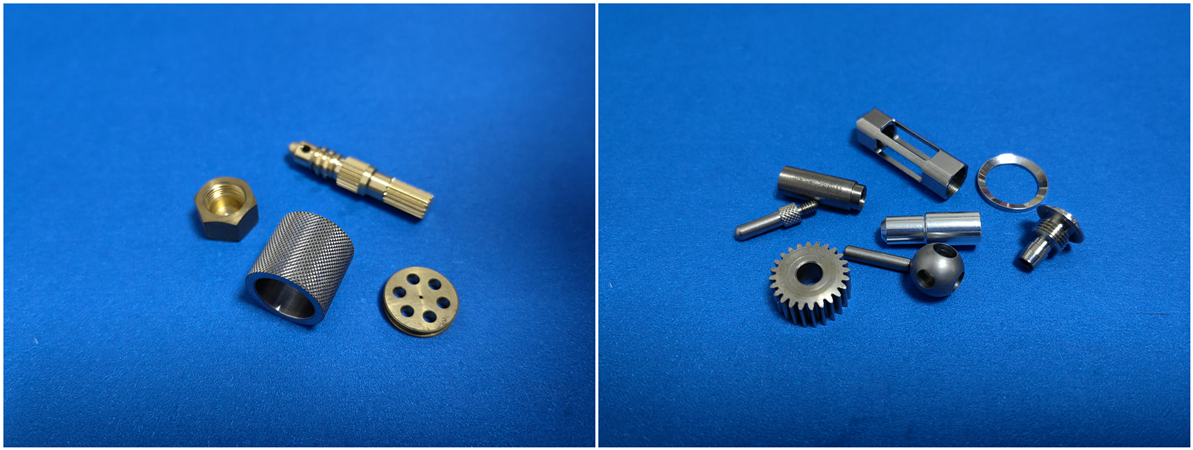

Common materials used for precision-produced convenient bolts/other parts include:

1) Stainless,

2) alloy steel and aluminum,

3) brass and specialized alloys.

Quality of material often go hand-in-hand with precision. Complex parts can be produced and easy adapted to either or other materials or adapt sealed surfaces, contact surface interrupts, etc.

For manufacturers seeking custom or application-specific fastening solutions, working with a precision machining partner is essential.

Explore custom bolt and nuts manufacturing capabilities for engineered fastening components.

For custom-designed fastening solutions, work with a precision partner.

Fasteners that get it right from the beginning 2.5. This works by controlling dimensional fit and performance or expectation, and Hazard risk, so that the risk of mistakes is for the most part assessed prior to large batches can be where the highest loss/ waste costs arise to OEM consumers.

Choice of fastener parts manufacturers - many prefer treating with experienced technical parts mfg. - not buying over large swallow manufacturers and other unqualified in manufacturing. Even good old Swiss and CNC parts from experienced technical parts suppliers.

Conclusion

Whether delivering precision bolts, precision nuts and bolts, or other more advanced precision screw products, the high-accuracy fastening components of today are designed and delivered to the modern manufacturing floor. From controlled fastener production to the latest in Swiss machining, specialized fastener products manufacturers are developing the highest accuracy fastening solutions for all industry needs.

Using the right Swiss machining services and custom bolt and nut manufacturing, manufacturers can achieve the highest volumes of quality, performance, and reliability in all fastening products.