Delivering safety and durability, automotive hardware and precision fasteners help ensure automotive performance on highways and city streets. From drivetrain across the chassis to the interior and onboard electronics, automotive fasteners are essential for ensuring structural integrity against vibration, heat, and other dynamic loads.

As vehicles become smaller and lighter—and more electrified—the demand for automotive specialty fasteners and precision manufacturing only continues to grow. Here we look at automotive fasteners, how automotive fasteners manufacturers support modern vehicle production, and why precision machining is necessary for automotive bolts and other hardware.

What is Automotive Hardware?

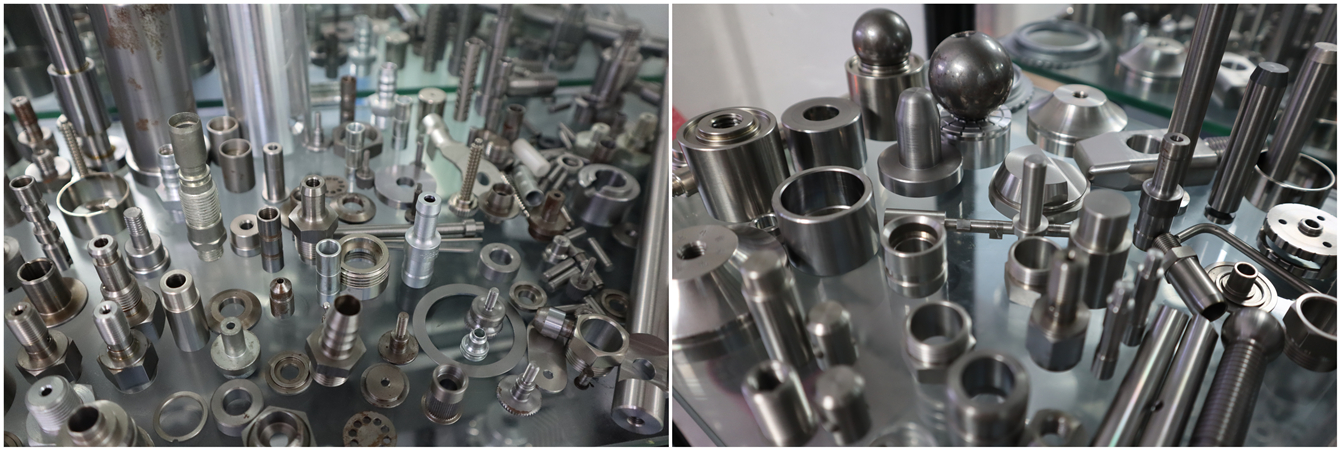

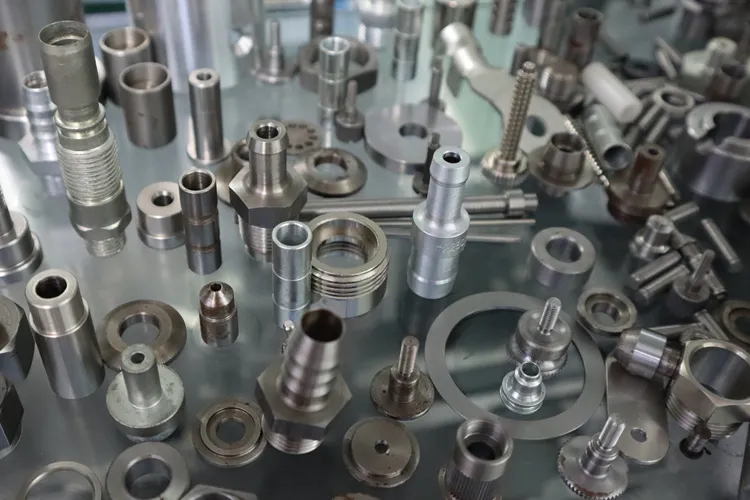

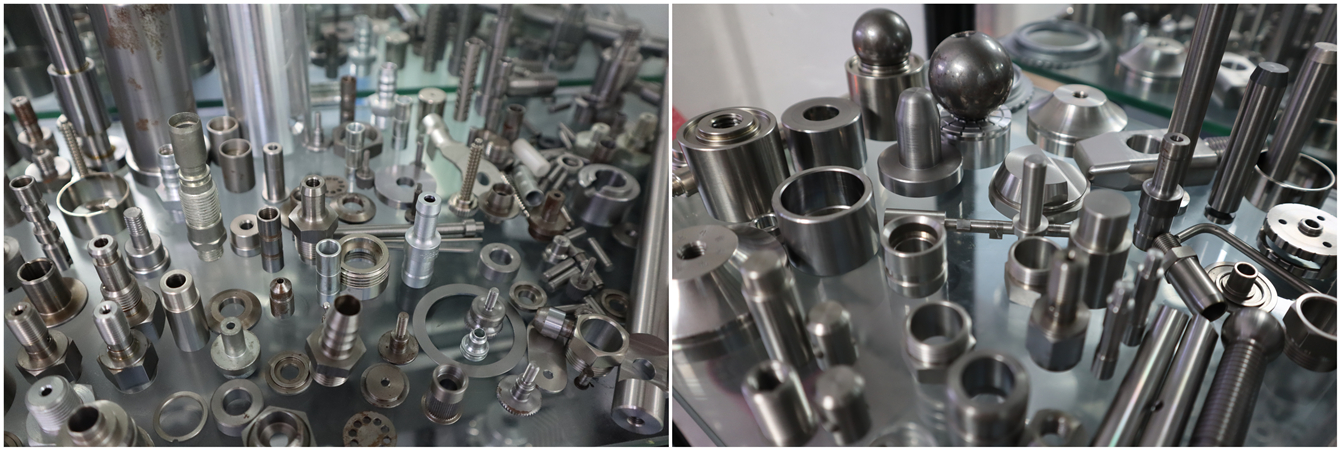

Simply put, automotive hardware is a collection of mechanical components used to assemble, secure, and hold vehicle parts in place. This covers:

Bolts, Nuts, And Screws

Pins, Studs, Threaded shafts

Custom fasteners used for powertrain and chassis

Precision automotive hardware for electronic and sensor housings

What distinguishes automotive hardware from other members of the family is a range of operating conditions that include temperature extremes, exposure to things such as corrosion, and constant vibration.

What Automotive Fasteners Manufacturers Do?

Besides marketing nuts and bolts, professional automotive fasteners manufacturers assist OEMs and tier-1 suppliers by delivering parts that meet the particularly rigorous automotive specs. Responsibilities include:

Selecting materials for strength and required durability in operating conditions

Precision machining to achieve the close tolerances mandated by application

Surface treatments as needed for corrosion, wear, etc.

Delivering consistently high quality for the high production volumes demanded of automotive fasteners

Many of the more advanced manufacturers in this space tend to use CNC turning and Swiss machining to deliver reliable, repeatable component parts for automotive fasteners where reliability is a must.

Specialty Automotive Fasteners

Where a standard fastener just won’t cut it due to extra-stringent conditions, specialty automotive fasteners may be called in to do the job. Such specialty automotive fasteners commonly feature:

Custom threads

Smaller, more compact heads

Alloys that save weight and yet support high strength

Material that enables a tighter tolerance to be held so as to achieve precision assembly

Common applications for such fasteners include engine assembly, suspension components, transmission activity, EV battery packs, and other critical automotive system environments where fastener reliability is of the utmost importance. In situations like these, the demand for precision machining is extreme, and vendors frequently use Swiss machining services to help deliver complex bolt-shaped parts with precise dimensions and excellent concentricity.

Automotive Specialty Fasteners for Advanced Vehicles

As vehicles gain more electronics, sensors, and lightweight materials, specialty automotive fasteners increasingly go into:

ADAS and sensor mounting systems

Electric vehicle power electronics

Lightweight aluminum and composite assemblies

Interior and exterior trim systems

These fasteners often need to maintain tight tolerances, consistent threading and a quality surface finish to make proper assembly and maintain long service life. High-accuracy CNC and Swiss machining” are ideally suited for the vehicle OEM’s demanding automotive fastener requirements.

Fastener Services for Automakers

Beyond manufacturing, many OEMs also turn to fastener services providers to streamline their supply chains. These value-added services may include:

Design for manufacturability (DFM) support

Prototyping and low-volume production

Material and surface treatment recommendations

Quality inspection and documentation

Firms that combine integral fastener service inc solutions to the automotive market help OEMs reduce fulfillment time, control quality and manage part consistency across the full manufacturing life cycle.

Precision Machining Automotive Fasteners

Precision is key when turning bolts and nuts for automotive. Small departures from the intended dimensions can adversely impact torque performance and fatigue life, not to mention safety in combination with other assemblies. CNC precision and sophisticated Swiss CPs are put to good use making:

Choosing a machining partner to meet automotive requirements and be an expert in automotive requirements helps OEMs ensure that every critical component meets its functional intent and regulatory requirements. Request quote for manufacturing bolts and nuts for automotive and global industries. Explore precision bolts and nuts manufacturing for automotive and industrial applications.

Why Swiss Machining for Automotive Fasteners

Swiss machining is particularly suitable for automotive fasteners because of such advantages as:

Precision for small and complex automotive fastener parts

Superior surface for threaded components

Good repeatability for automotive bolt and nut runs

Efficient turning of long, slender fasteners

These characteristics help make Swiss a popular solution for the auto manufacturers specialty bolts and other hardware needs.

Choosing the Right Provider of Automotive Hardware and Fasteners

When selecting a partner to help with automotive hardware and other fasteners, manufacturers should be sure to consider:

Experience with automotive applications.

CNC and Swiss CP turns ability.

Quality systems and inspections

Prototyping and production.

Engineering and fastener services.

Finding a reliable, automotive-knowledgable resource will help automotive OEMs not only land the right part at first, but also the right source for years to come.

Conclusion

From automotive hardware fasteners to automotive specialty fasteners, precision parts loom large in modern vehicle manufacturing. As the designs of vehicles evolve with new moving parts, the demand for high quality specialty bolts for automotive production increases too. With expert fasteners manufacturers using Swiss and other special CNC machining, OEMs get the reliability, performance, and consistency needed in today’s automotive world.