Choosing the right dowel pin manufacturer is critical for applications that require accurate alignment, repeatability, and long-term mechanical stability. Dowel pins are widely used across automotive, electronics, machinery, and precision assemblies where positional accuracy is essential.

In this article, we explain how dowel pins are produced, what differentiates professional dowel pins manufacturers, and how advanced CNC and Swiss machining technologies support high-quality pin manufacturing.

What Does a Dowel Pin Manufacturer Do?

A professional dowel pins manufacturer specializes in producing cylindrical pins used for locating, aligning, or fastening mechanical components. Unlike standard fasteners, dowel pins often require:

Tight diameter tolerances

Excellent straightness and concentricity

Consistent surface finish

Reliable material performance

To meet these requirements, many manufacturers rely on Swiss machining services for producing high-precision pins with superior repeatability.

Learn more about advanced Swiss machining services for precision pin manufacturing.

Dowel Pin Manufacturing Process Explained

The dowel pin manufacturing process typically involves several controlled steps to ensure dimensional accuracy and performance:

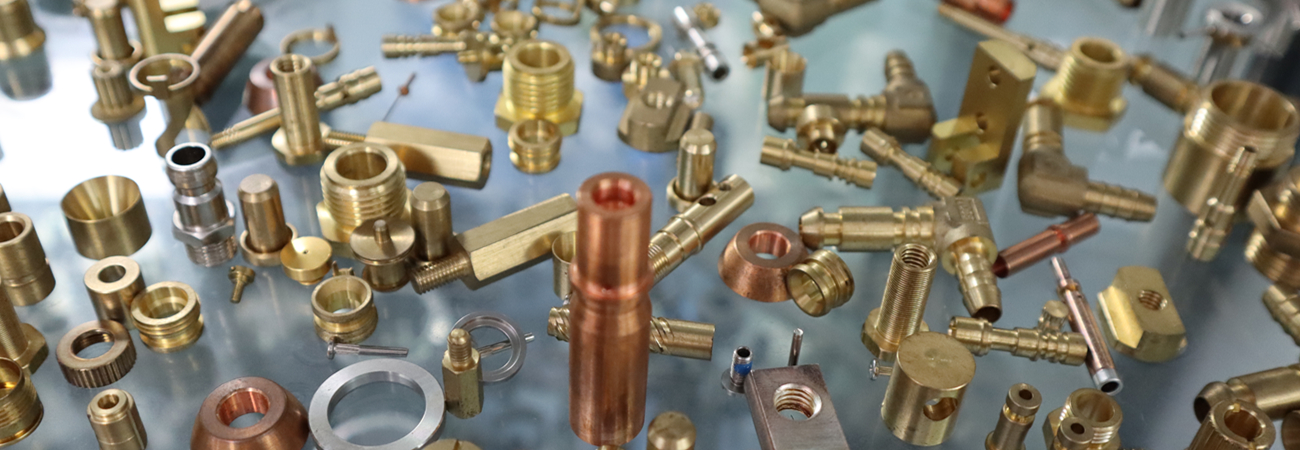

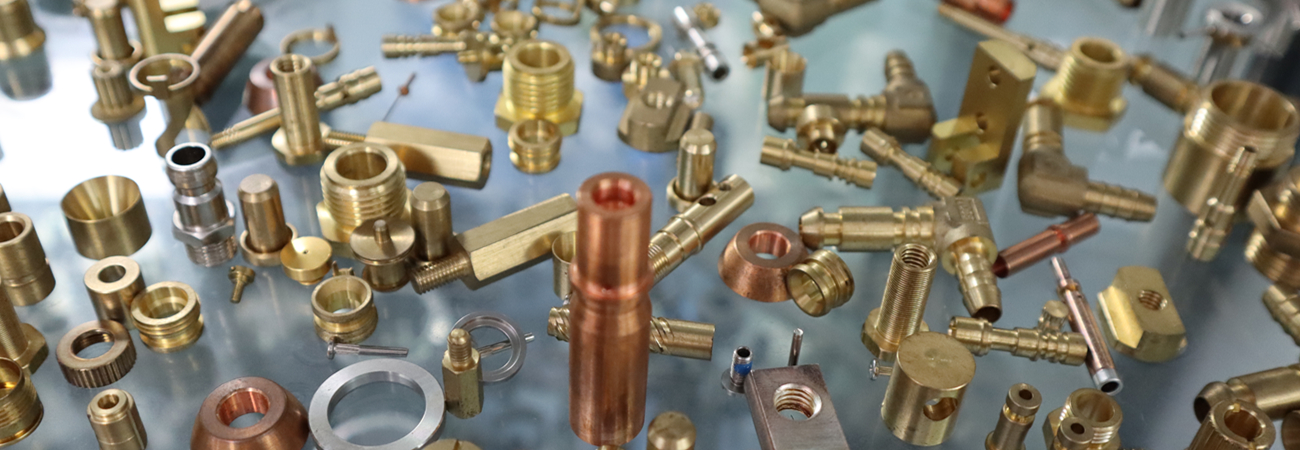

Material Selection – steel, stainless steel, brass, or specialty alloys

CNC Turning or Swiss Machining – for precise diameter and length control

Secondary Operations – chamfering, grinding, or polishing

Heat Treatment (if required) – to improve strength or wear resistance

Inspection and Quality Control – ensuring tolerance and consistency

Swiss-type CNC machines are especially effective for producing long, slender pins with tight tolerances, making them ideal for precision dowel pin applications.

Spring Dowel Pin Manufacturers and Their Applications

Spring dowel pin manufacturers produce slotted or coiled pins designed to provide flexibility and vibration resistance. These pins are commonly used in:

Spring dowel pins require precise slot geometry and controlled spring force, which demands stable machining processes and consistent quality control.

Custom Dowel Pin Manufacturers for Specialized Requirements

Standard pins do not always meet application-specific needs. That’s where custom dowel pin manufacturers add value by offering:

Custom diameters and lengths

Special chamfers or end forms

Tight tolerance control

Material and finish customization

Manufacturers with strong CNC and Swiss machining capabilities can efficiently support both prototyping and low-to-medium volume production of custom dowel pins.

Explore precision pins and shafts manufacturing for custom dowel pin solutions.

Brass Dowel Pins and Material Advantages

Brass dowel pins are widely used in applications that require corrosion resistance, electrical conductivity, or non-magnetic properties. Compared with steel, brass offers:

Because of these properties, brass dowel pins are commonly used in electronics, instrumentation, and light mechanical assemblies.

Reliable brass dowel pins suppliers typically focus on precision machining processes that maintain dimensional consistency while preserving surface quality.

Choosing the Right Brass Dowel Pins Suppliers

When evaluating brass dowel pins suppliers, consider the following factors:

Material certification and traceability

Dimensional tolerance capability

Surface finish quality

Experience with precision pin manufacturing

Ability to scale production

Suppliers that specialize in CNC and Swiss machining are often better equipped to deliver consistent quality for precision brass dowel pins.

Why Swiss Machining Is Ideal for Dowel Pin Manufacturing

Swiss machining is particularly well-suited for dowel pin production because it offers:

Exceptional precision for small diameters

Superior straightness and concentricity

High efficiency for long, slender parts

Stable quality across production runs

This makes Swiss machining a preferred solution for both standard and custom dowel pin manufacturing.

See how Swiss machining services support high-precision dowel pin production.

Conclusion

From standard locating pins to custom and spring-loaded designs, choosing the right dowel pin manufacturer is essential for ensuring performance and reliability. Experienced dowel pins manufacturers combine material expertise with advanced machining processes to deliver precision components for demanding applications.

Whether you are sourcing custom dowel pins, working with spring dowel pin manufacturers, or looking for reliable brass dowel pins suppliers, partnering with a manufacturer that offers advanced Swiss machining and precision pin capabilities can significantly reduce risk and improve product quality.